Introduction

Zirconium Dioxide Evaporation Materials (ZrO₂), also known as zirconia evaporation materials, are widely used in physical vapor deposition (PVD) processes for producing high-performance oxide thin films. Owing to their exceptional thermal stability, chemical inertness, and optical transparency, ZrO₂ materials are essential in optical coatings, electronic devices, and advanced protective layers. Their ability to form dense, durable films makes them a reliable choice for both research-scale evaporation and industrial vacuum coating systems.

Detailed Description

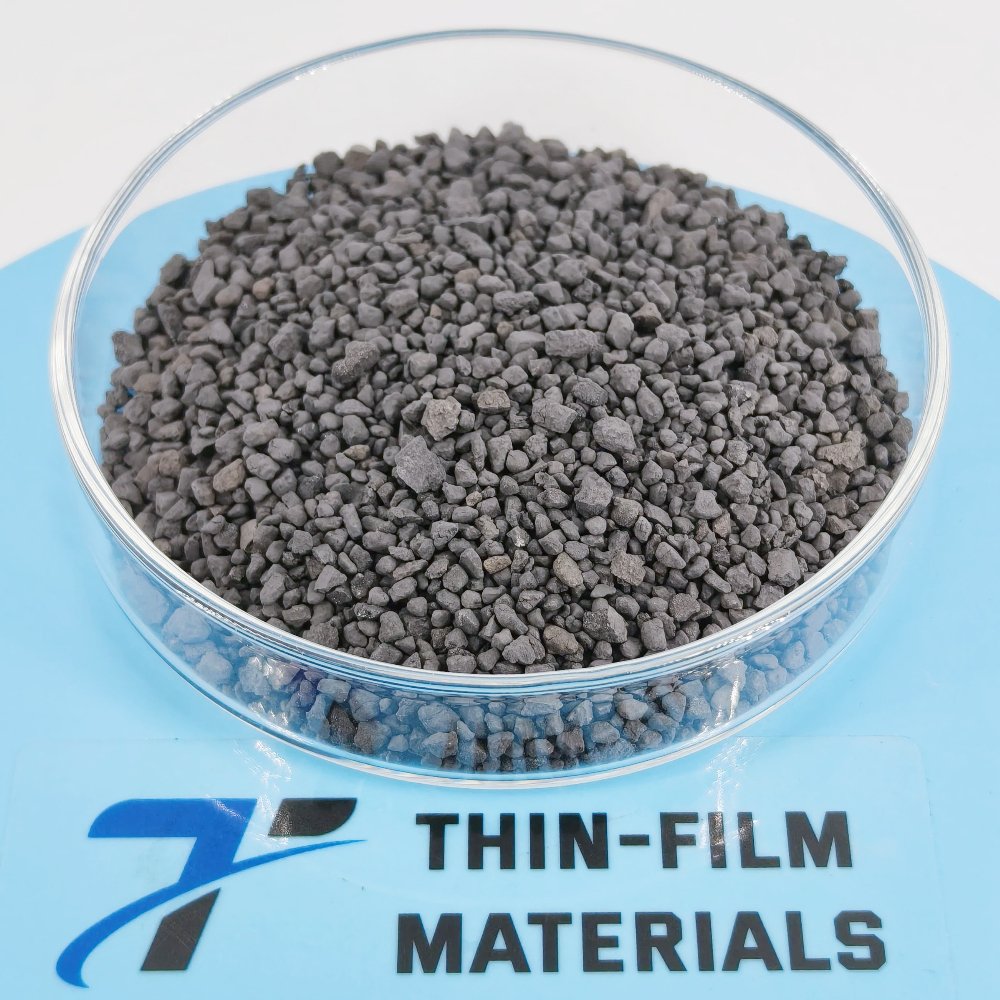

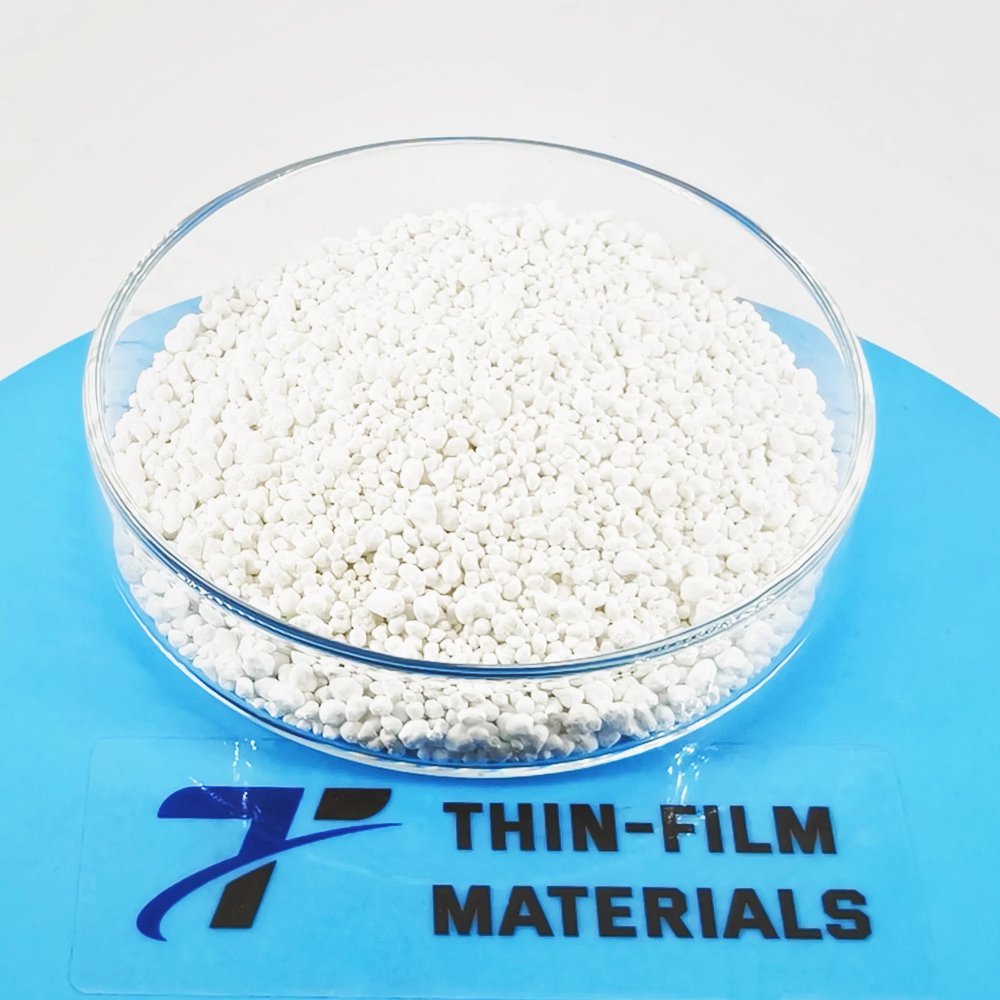

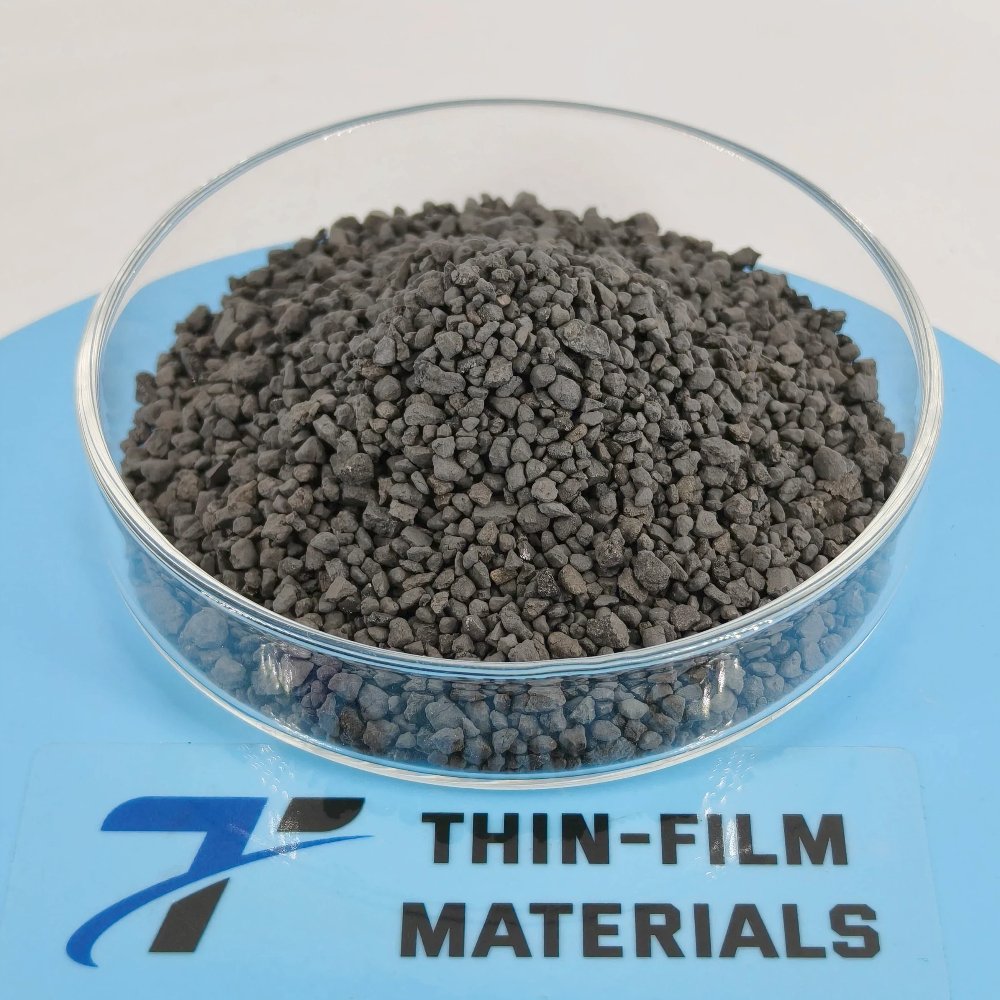

ZrO₂ evaporation materials are produced from high-purity zirconium oxide powders that undergo carefully controlled calcination, granulation, or sintering processes. This ensures consistent composition, low impurity levels, and stable evaporation behavior under high vacuum and elevated temperatures.

One of the key advantages of ZrO₂ is its extremely high melting point and strong resistance to chemical attack. These properties allow zirconium dioxide to maintain structural integrity during electron beam evaporation, thermal evaporation, and reactive evaporation processes. Compared with many other oxide materials, ZrO₂ offers superior film hardness, high refractive index, and excellent adhesion to a wide range of substrates.

Zirconium dioxide evaporation materials are typically supplied in pellets, granules, tablets, or custom-shaped pieces to suit different evaporation sources such as crucibles, boats, and e-beam hearths. Controlled particle size and morphology help achieve stable evaporation rates and uniform film thickness, especially in precision optical and electronic applications.

Applications

Zirconium Dioxide evaporation materials are commonly used in:

Optical coatings: High-refractive-index layers for lenses, mirrors, laser optics, and filters

Thermal barrier coatings: Heat-resistant layers for aerospace and high-temperature components

Semiconductor devices: Dielectric and insulating films in microelectronic structures

Decorative coatings: Durable, wear-resistant finishes with excellent color stability

Energy and functional coatings: Protective and insulating layers in advanced energy systems

R&D thin-film studies: Material research involving oxide ceramics and multilayer stacks

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Chemical Composition | ZrO₂ (Zirconium Dioxide) | Defines thermal and optical performance |

| Purity | 99.9% – 99.99% | Minimizes contamination in deposited films |

| Form | Pellets, granules, tablets, custom shapes | Matches different evaporation sources |

| Particle Size | Custom controlled | Influences evaporation stability |

| Melting Point | ~2700 °C | Enables high-temperature evaporation processes |

| Evaporation Method | E-beam / Thermal | Flexible compatibility with PVD systems |

Comparison with Related Oxide Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| ZrO₂ | High refractive index, excellent thermal stability | Optical & protective coatings |

| Al₂O₃ | Good insulation, lower refractive index | General dielectric coatings |

| HfO₂ | Higher density, high-k dielectric | Semiconductor devices |

| TiO₂ | Strong optical absorption control | Decorative and optical films |

FAQ

| Question | Answer |

|---|---|

| Can ZrO₂ evaporation materials be customized? | Yes, purity, form, and particle size can be tailored to your process. |

| Which evaporation method is recommended? | Electron beam evaporation is commonly used due to ZrO₂’s high melting point. |

| How are the materials packaged? | Vacuum-sealed with moisture-proof protection for safe transport and storage. |

| Are these materials suitable for optical coatings? | Yes, ZrO₂ is widely used for high-index optical thin films. |

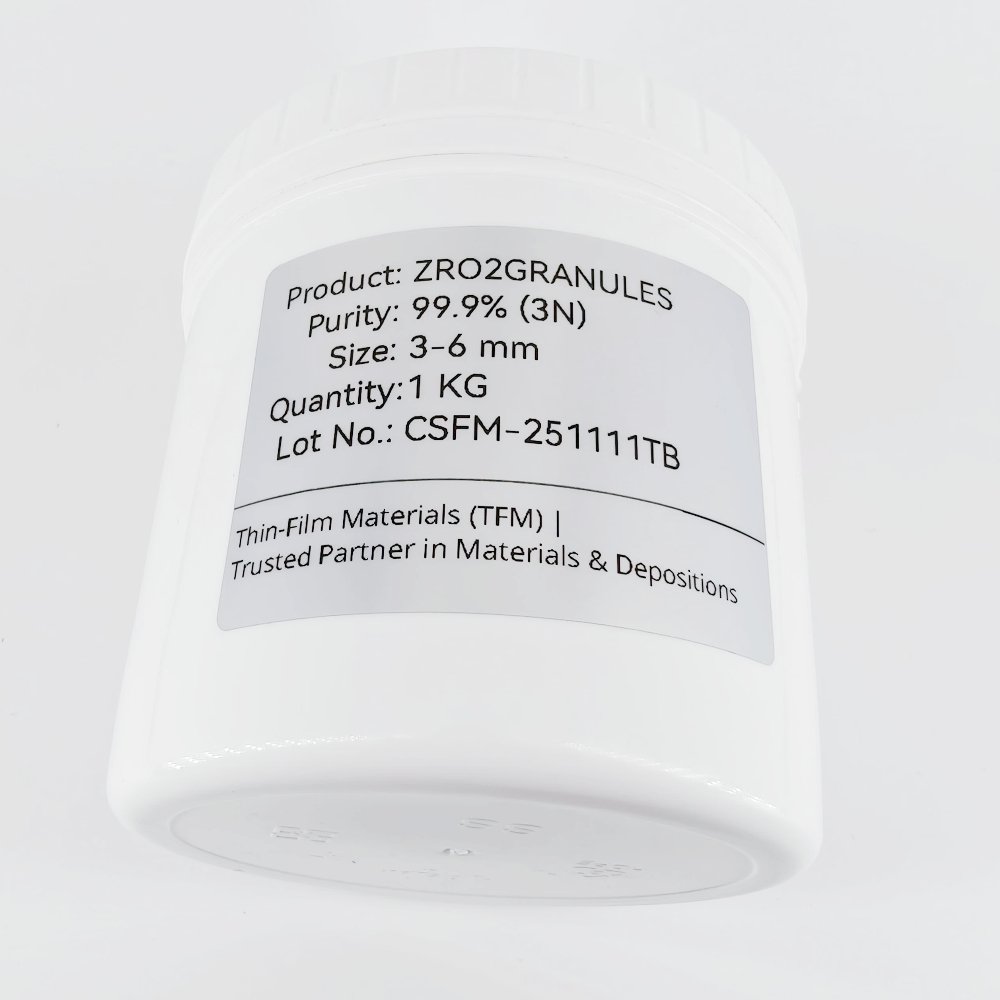

Packaging

Our Zirconium Dioxide Evaporation Materials (ZrO₂) are carefully labeled and securely packaged to ensure accurate identification and consistent quality control. Each batch is vacuum-sealed and protected with reinforced cushioning to prevent contamination, moisture exposure, or physical damage during storage and international transportation.

Conclusion

Zirconium Dioxide Evaporation Materials (ZrO₂) provide a robust and reliable solution for depositing high-quality oxide thin films with excellent thermal, optical, and mechanical performance. With flexible customization options and stable evaporation behavior, ZrO₂ is an ideal material for demanding optical, electronic, and protective coating applications.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

MSDS File

MSDS File

Reviews

There are no reviews yet.