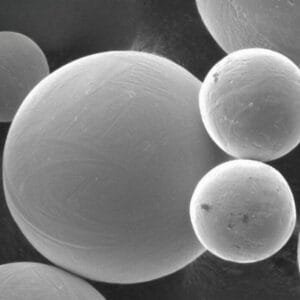

Zirconium Powder

TFM stands out as a top provider of premium zirconium powders, including Zirconium Powder, Nano Zirconium Powder, and Spherical Zirconium Powder specifically designed for 3D printing. Our products are crafted to meet the rigorous demands of diverse industrial applications.

Zirconium Powder Features

• Excellent corrosion resistance

• Application: Used in military industry to make fuze and pyrotechnic pharmaceutical materials, powder metallurgy, metal alloy raw materials, electron tube spraying, and arson materials for missiles

Chemical Composition of Zirconium Powder

| Grade | Chemical Composition (%) | |||||

| Zr+Hf | H | O | N | C | Fe | |

|---|---|---|---|---|---|---|

| ≥ | ≤ | |||||

| Zr | 99.5 | 0.01 | 0.05 | 0.006 | 0.01 | 0.042 |

| Zr-4 | – | 0.005 | 0.16 | 0.01 | 0.01 | 0.24 |

| Sieve mesh | -60mesh – +400mesh 1-3um, D50=0.5um | |||||

| Grade | Total Zr<% | Active Zr% | Chemical Composition (%) | |||||||

| Fe | Ca | Mg | Al | S | Cl | F | Flash Point | |||

|---|---|---|---|---|---|---|---|---|---|---|

| FZrb-11 | 92.0 | 70-80 | 0.20 | 0.05 | 0.05 | 0.04 | 0.03 | 0.003 | 0.008 | 280-370 |

| FZrb-12 | 270-350 | |||||||||

| FZrb-13 | 260-330 | |||||||||

| FZrb-21 | 95.0 | ≥90 | 0.20 | 0.05 | 0.05 | 0.04 | 0.03 | 0.003 | 0.008 | 270-340 |

| FZrb-22 | 250-330 | |||||||||

| FZrb-23 | 220-320 | |||||||||

| FZrb-1 | 96.0 | ≥90 | 0.20 | 0.05 | 0.05 | 0.04 | 0.03 | 0.003 | 0.008 | 200-280 |

| FZrb-2 | 96.0 | ≥92 | 0.20 | 0.05 | 0.05 | 0.04 | 0.03 | 0.003 | 0.008 | 200-280 |

| Grade | Standard sieve mesh (um) | Size | Average size (um) | |||||||

| <6um | <10um | 10-20um | >20um | |||||||

| FZrb-11 | 63 | – | 17-27 | 28-43 | 35-50 | 18±3 | ||||

| FZrb-12 | 63 | – | 34-45 | 25-40 | 15-30 | 13±3 | ||||

| FZrb-13 | 63 | – | 50-70 | 28-43 | <10 | 9±2 | ||||

| FZrb-21 | 63 | – | 17-27 | 28-43 | 35-50 | 13±3 | ||||

| FZrb-22 | 63 | – | 35-45 | 25-40 | 15-30 | 13±2 | ||||

| FZrb-23 | 63 | – | 50-70 | 28-43 | <10 | 9±2 | ||||

| FZrb-1 | 45 | ≥80 | – | – | – | 6±2 | ||||

| FZrb-2 | 45 | ≥90 | – | – | – | 6±2 | ||||

| Special requirements to be agreed upon by the supplier and buyer | ||||||||||

Reviews

There are no reviews yet.