1. Introduction

The global shift toward electrification of transportation has created an urgent need for advanced energy storage systems. Among these, solid-state batteries (SSBs) are gaining prominence due to their potential to deliver higher energy densities, improved safety, and longer life spans compared to traditional lithium-ion batteries. A critical component in the development of SSBs is the solid electrolyte, particularly when engineered into thin films for efficient ion transport and compact cell architectures. This article delves into the application of solid-state batteries in new energy vehicles (NEVs), with a particular focus on solid electrolyte thin films based on materials such as Lithium Lanthanum Zirconium Oxide (LLZO) and Lithium Germanium Phosphorus Sulfide (LGPS), their sputtering targets, and prefabricated film technologies.

2. Why Solid-State Batteries Matter

Conventional lithium-ion batteries have enabled the first wave of NEVs, but they come with inherent limitations:

- Safety risks due to flammable liquid electrolytes

- Limited energy density, constrained by separator thickness and electrode design

- Dendrite growth, which can cause short circuits and thermal runaway

- Degradation mechanisms at the electrode-electrolyte interface

SSBs eliminate many of these issues by replacing the liquid electrolyte with a solid counterpart. The solid electrolyte acts as both an ionic conductor and a physical separator, mitigating dendrite penetration and enabling the use of lithium metal anodes, which have much higher theoretical capacities.

3. Overview of Solid Electrolytes

Solid electrolytes can be broadly classified into three categories:

- Oxide-based (e.g., LLZO, LATP)

- Sulfide-based (e.g., LGPS, LPSCl)

- Polymer-based (e.g., PEO-LiTFSI composites)

The choice of electrolyte depends on several factors, including ionic conductivity, electrochemical stability, mechanical properties, processability, and compatibility with electrodes. Oxide and sulfide electrolytes dominate current research due to their superior conductivity and stability, making them prime candidates for thin-film applications in NEVs.

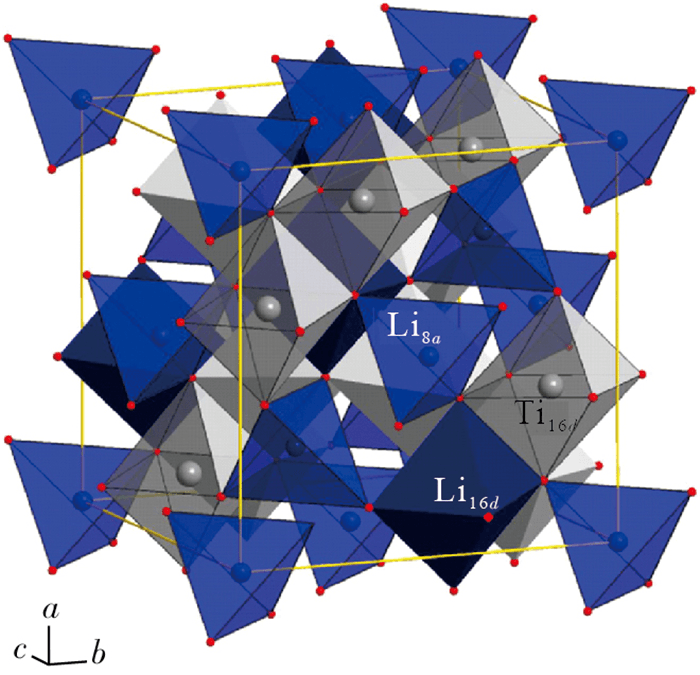

4. LLZO: Garnet-Type Oxide Electrolyte

Lithium Lanthanum Zirconium Oxide (LLZO) is a garnet-structured oxide that has shown promising ionic conductivities in the range of 10^-4 to 10^-3 S/cm at room temperature.

Key features:

- High ionic conductivity when doped (e.g., with Ta, Al, Ga)

- Stability against lithium metal

- Wide electrochemical window (~0-6V vs. Li/Li+)

- High thermal and chemical stability

However, LLZO’s brittleness and high sintering temperatures pose manufacturing challenges, particularly for large-scale film fabrication.

5. LGPS: Sulfide-Based Superionic Conductor

Lithium Germanium Phosphorus Sulfide (LGPS) exhibits even higher ionic conductivities (~10^-2 S/cm), rivaling that of liquid electrolytes.

Key features:

- Excellent lithium-ion transport

- Low processing temperatures

- Easier densification and adhesion to electrodes

The downside lies in its sensitivity to moisture and air, requiring stringent manufacturing controls to prevent degradation.

6. Thin Film Electrolytes: A Strategic Advantage

Thin film electrolytes enable:

- Reduced internal resistance

- Enhanced interfacial contact with electrodes

- Space-saving designs for compact battery architectures

They are especially useful in:

- Micro-batteries

- Stacked multilayer pouch cells

- Hybrid film-stack solid-state EV batteries

The precision required for these films necessitates advanced deposition techniques such as:

- Magnetron sputtering

- Pulsed laser deposition (PLD)

- Atomic layer deposition (ALD)

7. Sputtering Targets for LLZO and LGPS

Sputtering targets are critical raw materials in the production of thin films. High-purity, dense targets are essential for achieving uniform deposition and film integrity.

LLZO Targets

- Usually sintered ceramics with purities of 99.9% or higher

- Doping with elements like Ta or Al enhances conductivity

- Backing plates (typically copper or molybdenum) help manage thermal loads during sputtering

LGPS Targets

- Fragile and sensitive to environmental conditions

- Often produced using hot-press techniques under inert atmospheres

- Require glove box handling and sealed transportation

8. Manufacturing Considerations

The transition from lab-scale development to commercial-scale production presents multiple challenges:

- Target fabrication: Requires precise control of stoichiometry and microstructure

- Deposition systems: Must accommodate reactive gases and controlled environments

- Substrate preparation: Critical for adhesion and crystallinity of the film

- Post-deposition treatments: May include annealing to improve phase formation and conductivity

9. Integration in Battery Cells

SSBs using thin film electrolytes are constructed via layer-by-layer deposition:

- Substrate (e.g., stainless steel, silicon wafer)

- Current collector (e.g., platinum, gold)

- Cathode layer (e.g., LCO, NMC)

- Solid electrolyte (e.g., LLZO, LGPS film)

- Lithium metal anode or alloy

This structure ensures minimal interfacial resistance and maximizes ionic transport efficiency.

10. Benefits in New Energy Vehicles

Thin-film solid electrolytes can significantly enhance NEV battery performance:

- Increased range: Due to higher energy densities and lithium metal compatibility

- Faster charging: Enabled by higher ionic conductivity and thermal stability

- Improved safety: No flammable liquids, reduced thermal runaway risk

- Longer lifespan: Stable interfaces and reduced degradation

11. Companies and Research Trends

Major automakers and battery firms are actively investing in SSB technologies:

- Toyota: Oxide-based solid-state prototypes with LLZO films

- QuantumScape: Developing multilayer pouch cells using sulfide electrolytes

- Samsung: Research into ultrathin sulfide-based separators

- Solid Power: Working on scalable oxide-based SSBs with tape casting and sputtered layers

12. Challenges and Future Directions

Despite the promise, several hurdles remain:

- High cost of sputtering targets

- Scalability of thin-film deposition techniques

- Material compatibility at interfaces

- Long-term cyclability and mechanical integrity

Research directions include:

- Co-sputtered doped LLZO films

- Hybrid oxide-sulfide multilayers

- Roll-to-roll sputtering systems

- In-situ diagnostics for film quality

13. Conclusion

Solid-state batteries are a cornerstone in the future of NEVs, and thin-film solid electrolytes play a pivotal role in enabling high-performance architectures. Materials such as LLZO and LGPS, when used as sputtering targets or prefabricated films, form the foundation of scalable, safe, and energy-dense solutions. As deposition technologies and material science continue to evolve, the path to mass adoption becomes increasingly clear.

14. You May Also Want to Know (FAQs)

- What is the role of a sputtering target in solid-state battery production?

- It provides the source material for vapor deposition of solid electrolyte films.

- Why are LLZO and LGPS preferred over other electrolytes?

- Their high conductivity and chemical stability make them ideal for thin film applications.

- Can solid-state batteries really eliminate the risk of fire?

- They significantly reduce the risk due to the absence of flammable liquid electrolytes.

- How thin are solid electrolyte films in EV batteries?

- They can range from 100 nanometers to a few micrometers.

- What purity is required for sputtering targets?

- Typically 99.9% or higher.

- Are there prefabricated thin film options available?

- Yes, several suppliers offer pre-laminated or pre-deposited films.

- How do these films improve fast charging capabilities?

- Their ionic conductivity allows for quicker lithium transport and heat tolerance.

- Do these films support lithium metal anodes?

- Yes, they provide a physical barrier to dendrites and support high-capacity anodes.

- Are sputtered films scalable for mass production?

- Technologies like roll-to-roll sputtering are being developed for this purpose.

- When will we see solid-state EVs on the road?

- Many industry experts predict mainstream adoption between 2026 and 2030.