Introduction

Yttrium, a rare earth element with atomic number 39, has gained significant attention due to its unique properties and diverse applications. When processed into a spherical powder form, yttrium exhibits enhanced characteristics that are invaluable across various industries. This article explores the properties, applications, and market trends of spherical yttrium powder, highlighting its importance in modern technology and industry.

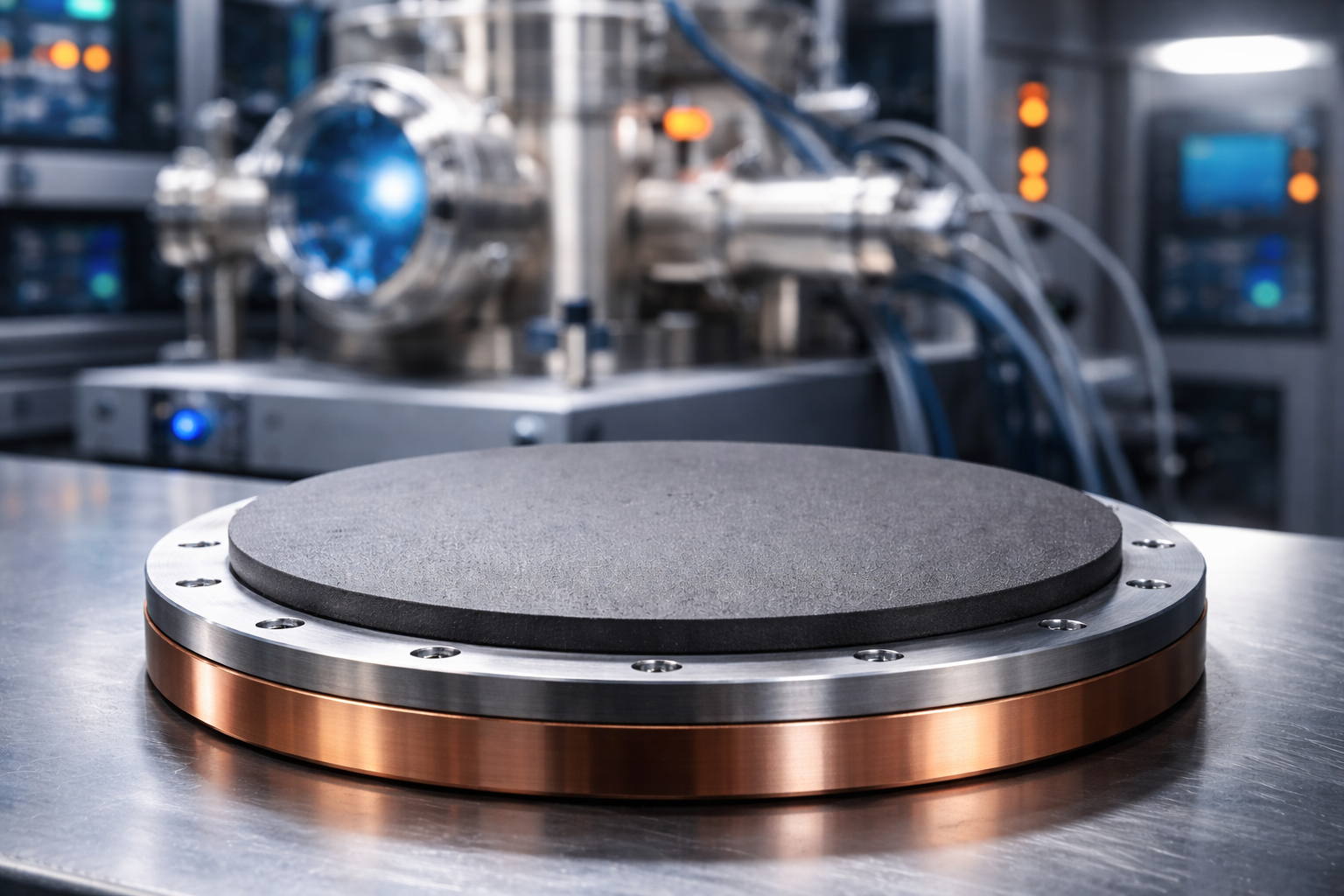

Properties of Spherical Yttrium Powder

Spherical yttrium powder is notable for its uniform, spherical morphology, which provides superior flowability and packing density compared to irregularly shaped particles. This characteristic is particularly beneficial in processes like additive manufacturing and thermal spraying, where consistent powder flow is essential.

The powder typically boasts high purity levels, often exceeding 99.9%, ensuring minimal contamination in sensitive applications. Its density is approximately 4.469 g/mL at 25°C, and it has a melting point of 1522°C, making it suitable for high-temperature applications. The particle size distribution can be customized, with common median particle sizes (D50) around 45 micrometers, though finer or coarser powders are available based on specific requirements.

Applications of Spherical Yttrium Powder

The unique properties of spherical yttrium powder make it a material of choice in several advanced technological applications:

1. Thermal Spraying and Coatings

Spherical yttrium oxide powder is extensively used in thermal spraying techniques to produce coatings that are resistant to high temperatures and corrosion. These coatings are essential in protecting components in industries such as aerospace and energy. The spherical shape of the powder ensures efficient flow and uniform deposition during the spraying process.

2. Additive Manufacturing

In the realm of additive manufacturing, or 3D printing, spherical metal powders are preferred due to their excellent flowability and packing characteristics. Spherical yttrium powder is utilized in producing complex components that require high precision and material integrity.

3. Alloying Additive

Yttrium serves as an additive in various alloys to enhance their mechanical properties. When added to magnesium and aluminum alloys, yttrium improves strength and reduces grain size, leading to materials that are both lightweight and robust. These enhanced alloys find applications in the automotive and aerospace sectors, where material performance is critical.

4. Catalysts

Yttrium-based compounds function as catalysts in numerous chemical reactions. In the petrochemical industry, yttrium catalysts are employed in the production of high-density polyethylene, a widely used plastic. The effectiveness of yttrium in catalytic processes contributes to more efficient and sustainable chemical manufacturing.

5. Electronics and Phosphors

Yttrium oxide is a critical component in the production of phosphors, especially the red phosphors used in display technologies such as cathode ray tubes and LED screens. The incorporation of yttrium enhances the brightness and color quality of these displays, contributing to improved visual experiences in consumer electronics.

Market Trends

The global market for yttrium, including spherical yttrium powder, has been experiencing steady growth. In 2024, the market was valued at approximately USD 114.9 million and is projected to reach around USD 179.92 million by 2034, growing at a compound annual growth rate (CAGR) of 4.6%.

This growth is driven by increasing demand in sectors such as electronics, aerospace, and additive manufacturing. The unique properties of spherical yttrium powder make it indispensable in these industries, particularly for applications requiring high-performance materials.

Regionally, East Asia is expected to hold a significant share of the yttrium market, accounting for approximately 34.7% by 2034. This dominance is attributed to the robust electronics manufacturing industry in countries like China, Japan, and South Korea. Additionally, Mexico is anticipated to witness a notable growth rate of 7.4% during the same period, reflecting the expanding industrial base in the region.

Comparison of Spherical Yttrium Powder Properties

To provide a clearer understanding of the characteristics of spherical yttrium powder, the following table summarizes its key properties:

| Property | Description |

|---|---|

| Purity | ≥ 99.9% |

| Density | 4.469 g/mL at 25°C |

| Melting Point | 1522°C |

| Particle Size | D50: 45 µm (customizable) |

| Morphology | Spherical |

| Applications | Thermal spraying, additive manufacturing, alloying additive, catalysts, electronics |

Conclusion

Spherical yttrium powder stands out as a material of significant importance across various high-tech industries. Its unique properties, including high purity, spherical morphology, and excellent thermal stability, make it a preferred choice for applications ranging from thermal coatings to additive manufacturing. As market trends indicate continued growth, the role of spherical yttrium powder in advancing technology and industry is poised to expand further, solidifying its position as a critical material in the modern world.