1. Introduction

Tantalum box heaters have become a critical class of high-temperature components in modern physical vapor deposition (PVD) systems, vacuum furnaces, semiconductor processing tools, and research reactors requiring stable, contamination-free thermal environments. As thin-film engineering continues to advance toward higher precision, lower defectivity, and more demanding thermal loads, the performance of heating assemblies inside vacuum chambers plays a decisive role in determining coating quality, reproducibility, and equipment lifespan.

Among refractory metals, tantalum stands out for combining ultra-high melting temperature, excellent chemical inertness, low vapor pressure, and strong mechanical stability even in extreme thermal cycling. These characteristics make tantalum box heatersTantalum Box Heaters—a box-shaped or shield-shaped heating assembly fabricated from high-purity tantalum—one of the most reliable heater designs for vacuum applications exceeding 1500–2000 °C.

This article provides a detailed technical overview of tantalum box heaters, including their design principles, materials science background, thermal performance characteristics, fabrication methods, integration into vacuum systems, and their increasingly important role in high-precision PVD evaporation, annealing, and material development. It also offers practical guidance for engineers selecting heating components for advanced thin-film processes.

2. What Is a Tantalum Box Heater?

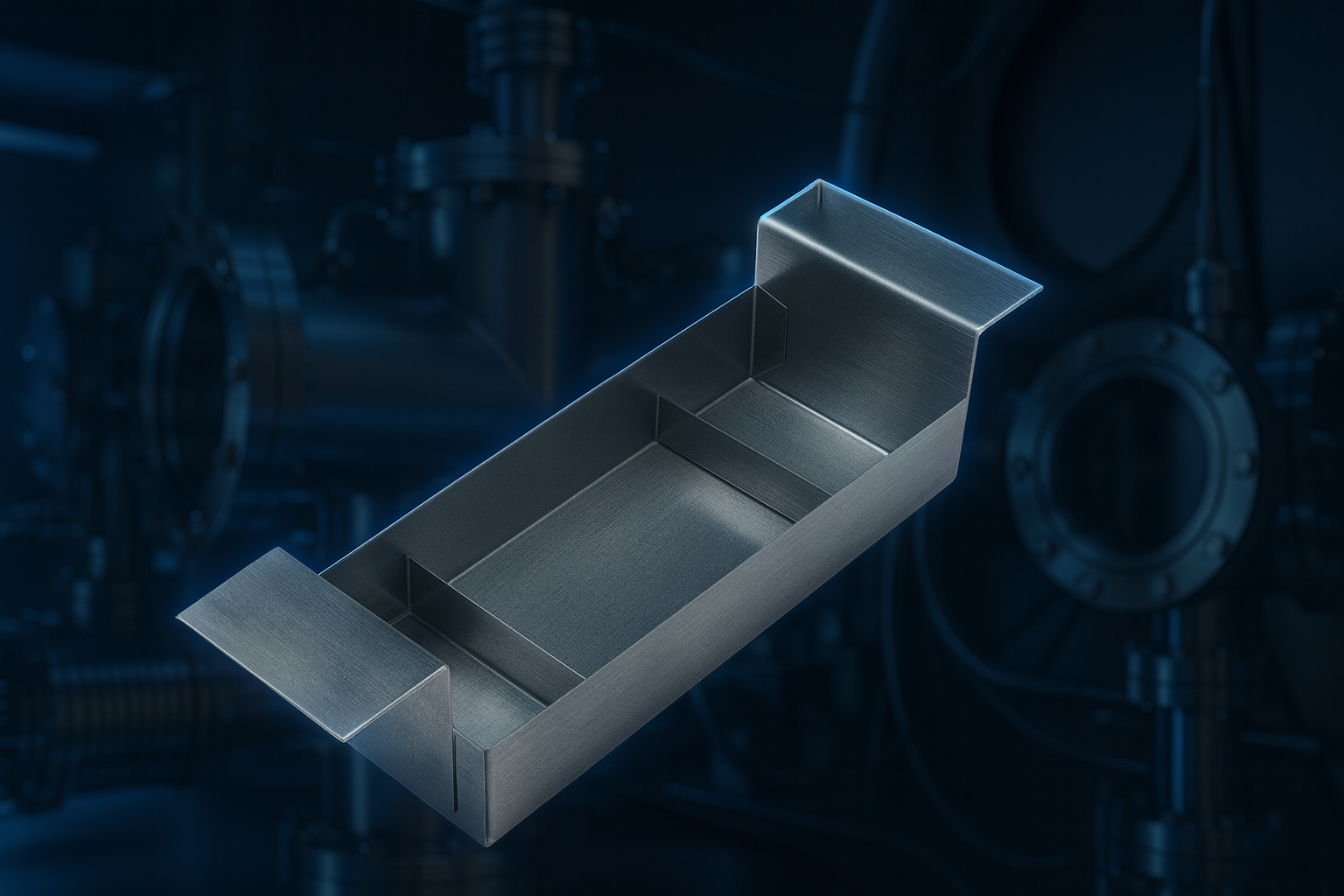

A tantalum box heater is a high-temperature heating assembly constructed from high-purity tantalum sheets, plates, wires, or strips, formed into a partially enclosed box-like geometry. The open top allows heat to radiate toward the substrate or evaporation material, while the sidewalls reduce heat loss and stabilize temperature distribution.

While the exact configuration varies by equipment manufacturer, common features include:

A box or trough-shaped tantalum enclosure

Internal heating elements (Ta strips, Ta wire, or Ta ribbon)

Electrical feedthrough tabs for connection to the power supply

Optional thermal shielding layers to enhance efficiency

A rigid structure designed to withstand hundreds of thermal cycles

The geometry is especially suited for evaporation sources and small thermal processing zones that require:

High uniformity

Low contamination

Stable radiative heat transfer

Tantalum’s unique physical characteristics make it exceptionally fit for this type of heater design.

3. Material Science Basis: Why Tantalum?

Tantalum (Ta, atomic number 73) is classified as a refractory metal. Its properties contribute directly to heater performance in vacuum and inert atmospheres:

3.1 Ultra-High Melting Point

- Melting temperature: 3017 °C

- Boiling temperature: 5458 °C

- Allows stable heater operation in the 1500–2200 °C range

These temperatures exceed those safely achievable with most common heating metals, including Ni-Cr alloys, molybdenum, and even some tungsten applications where brittleness is a concern.

3.2 Very Low Vapor Pressure

At elevated temperatures, many metals—especially chromium, nickel, aluminum, and iron—evaporate easily. Their vapor contaminates coatings and equipment.

Tantalum’s extremely low vapor pressure keeps the heater from outgassing and helps maintain ultra-clean vacuum environments.

3.3 Chemical Stability

Tantalum resists:

- Oxidation (at high temperatures in reduced environments)

- Most acids

- Halogens at moderate temperature

- Metal-to-metal reactions with evaporants

This stability makes it ideal for processes where contamination must be minimized.

3.4 Good Workability for Complex Shapes

Compared with tungsten, tantalum is more ductile and can be:

- Bent

- Folded

- Stamped

- Laser-cut

- Deep-drawn

This manufacturability enables the versatile box-shaped configurations needed for vacuum heaters.

4. Internal Design and Working Principles of Tantalum Box Heaters

4.1 Radiative Heating Mechanism

In a vacuum, conduction and convection are negligible. Therefore, almost all heat transfer is through thermal radiation.

The box enclosure maximizes radiative efficiency by:

- Redirecting radiated heat upward or inward

- Reducing heat loss to chamber walls

- Stabilizing internal thermal gradients

4.2 Heating Element Configurations

Internal heaters are commonly fabricated using:

- Tantalum strip heaters

- Tantalum wire spirals

- Tantalum ribbon elements

- Segmented resistive Ta components

Engineers select the appropriate format depending on:

- Desired resistance value

- Required heating rate

- Evaporant placement

- Uniformity needs

4.3 Enclosure Functions

The box walls provide:

- Thermal shielding

- Mechanical protection for the heating element

- Enhanced uniformity through multiple reflections

- Contamination containment

For evaporation processes, this is crucial to prevent unwanted splashing of molten materials.

4.4 Electrical Feedthroughs

Careful engineering is required because tantalum has:

- Moderate electrical resistivity

- High thermal conductivity

Terminals must be shaped to minimize hot spots and allow stable high-current operation.

5. Typical Fabrication Processes

Engineering-grade tantalum box heaters require multiple high-precision fabrication steps:

5.1 Material Preparation

Raw material: ≥99.95% Ta (3N5) or ≥99.99% Ta (4N)

Forms used:

- Ta plate (0.3–1.0 mm)

- Ta foil (0.05–0.3 mm)

- Ta wire/ribbon

Material must undergo:

- Vacuum annealing

- Grain control

- Surface polishing or cleaning

to achieve stable electrical behavior.

5.2 Forming the Box Geometry

Fabrication techniques include:

- CNC laser cutting

- Precision bending and folding

- TIG or resistance welding

- Electron-beam welding for high-purity joints

5.3 Integrating Heating Elements

The heating element is mounted inside the enclosure using:

- Tantalum standoffs

- Crimped joints

- Welded tabs

- Mechanical clamping (less common)

A good heater will feature uniform spacing, predictable thermal profiles, and stable electrical resistance across cycles.

5.4 Final Annealing

A vacuum anneal at high temperature:

- Relieves stress

- Improves grain uniformity

- Ensures dimensional stability during operation

This step is essential for long-term reliability.

6. Thermal Performance and Operating Characteristics

6.1 Temperature Capability

Typical operating temperatures:

1600–2200 °C in high vacuum

(lower limits may apply in the presence of oxygen)

6.2 Heating Efficiency

The box geometry enhances:

- Radiative flux concentration

- Peak temperature uniformity

- Energy efficiency by reducing wasted radiation

6.3 Ramp Rates

Well-designed tantalum heaters can tolerate:

- Fast ramp-up cycles

- Rapid cooldown cycles

without cracking or deformation, thanks to tantalum’s ductility.

6.4 Chemical Compatibility

Suitable for heating:

- Metals (Al, Cu, Ag, Au, Ni, Cr, Ge, Mg, Ti, etc.)

- Semiconductors

- Oxides

- Nitrides

- Sulfides

- Alloys requiring oxygen-sensitive environments

6.5 Lifespan Considerations

Factors affecting operational lifetime:

- Thermal cycling frequency

- Maximum temperature reached

- Electrical loading

- Evaporant reactivity

- Vacuum quality

A high-quality tantalum box heater can perform reliably through hundreds of cycles.

7. Applications in Advanced Technologies

7.1 PVD Thermal Evaporation Sources

Tantalum box heaters are widely used in:

- Electron-beam evaporation systems

- Resistive evaporation systems

- Multilayer optical coating tools

- Semiconductor metallization chambers

They are especially suitable for evaporating materials like:

- Aluminum

- Gold

- Nickel

- Chrome

- Germanium

- Magnesium

- Gallium compounds

- Oxide and nitride materials with strict purity needs

7.2 Semiconductor and Microelectronics Manufacturing

Tantalum heaters support processes such as:

- Annealing semiconductor wafers

- Crystallizing thin films

- Forming ohmic contacts

- Metallization layer formation

- Organic semiconductor treatment

7.3 Optical Coating and Photonics

For optics manufacturing, heaters help deposit:

- High-index oxides

- Infrared reflective films

- Anti-reflective multilayers

- Low-defect EUV coatings

- Dichroic and polarization coatings

The stable radiative field improves film uniformity and low-scatter performance.

7.4 Laboratory and R&D Environments

Tantalum heaters are favored in:

- Vacuum furnaces

- Material testing chambers

- Thin-film and nanomaterials synthesis

- High-temperature chemical reactions requiring low contamination

8. Performance Advantages Over Other Heater Types

8.1 vs. Tungsten Heaters

Tungsten is harder and more brittle. Tantalum offers:

- Better ductility

- Easier fabrication

- Improved corrosion resistance

- More robust cycling behavior

8.2 vs. Molybdenum Heaters

Molybdenum is less temperature-resistant and more reactive.

Tantalum provides:

- Higher melting point

- Lower vapor pressure

- Longer lifetime in vacuum

8.3 vs. Ceramic Heaters

Ceramic heaters cannot reach the same temperatures and may release impurities.

Tantalum is:

- Cleaner

- More stable

- More suitable for ultra-high purity processes

9. Engineering Considerations When Selecting a Tantalum Box Heater

9.1 Geometry and Size

Key parameters:

- Chamber footprint

- Distance to substrate

- Heat distribution requirements

9.2 Electrical Specifications

Design must determine:

- Target resistance

- Required current

- Maximum voltage

- Power loading capability

9.3 Thermal Shielding Integration

Adding extra Ta or Mo shields can:

- Reduce energy loss

- Improve uniformity

- Protect chamber walls

9.4 Compatibility With Evaporants

Tantalum generally performs well, but engineers must avoid:

- Highly reactive halides at high temperature

- Fluorides

- Certain carbides where reaction may occur

10. Maintenance and Best Practices

10.1 Handling

Tantalum is ductile but can scratch or crease during handling. Gloves are recommended.

10.2 Avoiding Oxidation

Exposure to air at high temperature must be avoided.

If oxidation occurs, the heater must be replaced.

10.3 Cleaning

Most contamination can be removed with:

- Vacuum baking

- Light polishing

- Solvent cleaning (depending on application)

10.4 Cycle Management

Longer lifespan is achieved by:

- Avoiding unnecessary thermal overshoots

- Using controlled ramp-up profiles

- Monitoring resistance drift over time

11. Future Trends: Why Tantalum Box Heaters Matter More Than Ever

As industries pursue:

- Higher temperature PVD

- Cleaner vacuum environments

- More complex multilayer coatings

- Emerging semiconductor materials (Ga₂O₃, GaN, SiC, perovskites)

- Low-defect optical coatings

the importance of stable, clean, high-temperature heaters increases.

Tantalum box heaters are positioned to remain indispensable for next-generation manufacturing.

12. Conclusion

Tantalum box heaters represent a mature yet continually evolving technology essential to high-temperature vacuum processing. Their combination of ultra-high melting point, extremely low vapor pressure, strong chemical stability, and excellent manufacturability makes them a natural choice for demanding thin-film deposition and material research applications.

Whether used in semiconductor thermal evaporation, optical coating systems, materials research furnaces, or high-purity chemical processes, tantalum box heaters deliver the uniformity, cleanliness, and reliability required in advanced manufacturing environments.

TFM supports custom engineering of tantalum heaters, from simple box geometries to complex multi-element assemblies, ensuring compatibility with diverse PVD systems and laboratory reactors.

For technical specifications, drawings, or a quotation, please contact:

sales@thinfilmmaterials.com