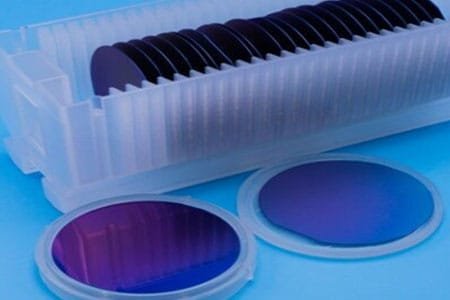

TFM Thermal Oxide Silicon Wafer – Your Trusted SiO₂ Wafer Provider

TFM offers high-quality Thermal Oxide Silicon Wafers (Si+SiO2), widely used in semiconductor, MEMS, and optoelectronic applications. These wafers consist of a silicon (Si) base layer with a precisely grown silicon dioxide (SiO₂) layer, providing superior electrical insulation, surface passivation, and enhanced device reliability.

Manufactured through a controlled thermal oxidation process, the SiO₂ layer ensures excellent uniformity, dielectric strength, and minimal defect density. These wafers are available in various oxide thicknesses, making them ideal for use in MOSFET fabrication, microfluidics, and optical coatings. Their high thermal and chemical stability allows for reliable performance in demanding environments.

TFM supplies customized Thermal Oxide Silicon Wafers tailored to meet the stringent requirements of research, industrial production, and advanced semiconductor development.

Thermal Oxide Silicon Wafer Specifications

| Size | 10×10, 15×15, 20×15, 20×20 (customized sizes available) <br> Dia 1″, Dia 2″, Dia 3″, Dia 4″, Dia 5″, Dia 6″, Dia 8″, Dia 12″ |

|---|---|

| Thickness | 0.3-0.5mm, 1.0mm |

| Polished | SSP or DSP |

| Orientation | <100>, <110>, <111> |

| Redirection Precision | ±0.5° |

| Redirection the Edge | 2° (special in 1°) |

Thermal Oxide Silicon Wafer Physical Properties

| Material | Si+SiO₂ |

|---|---|

| Structure | M3 |

| Melting Point | 1420°C |

| Density (g/cm³) | 2.4 g/cm³ |

| Doped Materials | Undoped, B-doped, P-doped |

| Type | P / N, P, N |

| Resistivity | >1000 Ωcm, 10⁻³ |

| Thermal Expansion | ≤100/cm² |

| Oxide Thickness | 300~500nm (customized sizes available) |

Reviews

There are no reviews yet.