Tungsten crucibles, recognized for their exceptional durability and resistance to extreme temperatures, are indispensable tools in numerous industrial and scientific applications. These high-performance containers are primarily fabricated from tungsten, a refractory metal known for its impressive melting point, density, and thermal conductivity. This article delves into the many uses of tungsten crucibles and explores the reasons behind their widespread adoption across diverse sectors.

Properties of Tungsten Crucibles

Understanding the unique properties of tungsten crucibles is essential to appreciating their utility. Tungsten is one of the densest metals, boasting a melting point of 3,422°C (6,192°F). Such characteristics make it exceptionally well-suited for high-temperature applications. Tungsten also exhibits:

High thermal conductivity: Ensures uniform heat distribution, reducing the risk of localized overheating.

Low thermal expansion coefficient: Maintains structural integrity under temperature fluctuations.

Corrosion resistance: Enhances longevity, even when exposed to reactive substances at elevated temperatures.

Excellent mechanical strength: Provides durability in demanding conditions.

These attributes render tungsten crucibles ideal for operations that require stability, precision, and reliability under harsh environments.

Applications of Tungsten Crucibles

High-Temperature Furnaces

Tungsten crucibles are extensively used in high-temperature furnaces for processes such as crystal growth, sintering, and annealing. The metal’s ability to withstand extreme temperatures without deformation or failure makes it ideal for these applications. In particular, tungsten crucibles play a crucial role in the production of synthetic sapphire and silicon carbide, materials essential for electronics and optics industries.

Metal Smelting and Refining

Metals with high melting points, such as platinum, titanium, and molybdenum, are often smelted and refined using tungsten crucibles. These crucibles ensure that the container does not react with the molten metal, preserving the purity of the material. Tungsten’s resistance to chemical interactions makes it indispensable in metallurgical processes.

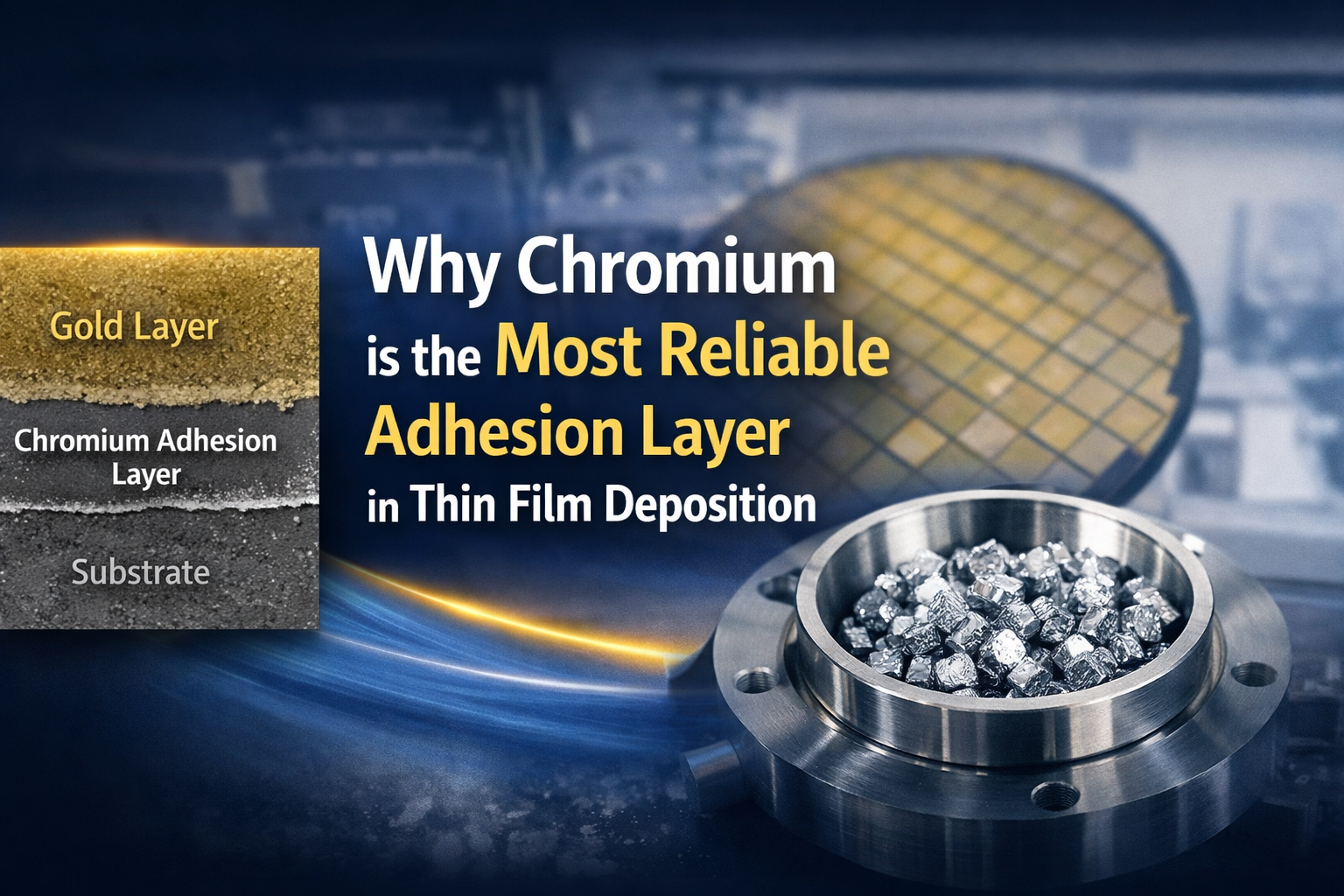

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)

In the semiconductor and thin-film industries, tungsten crucibles are integral to deposition techniques like CVD and PVD. These processes require high-precision heating in a controlled environment to deposit materials onto substrates, creating thin films for electronics, solar cells, and optical coatings. Tungsten crucibles provide the necessary thermal stability and non-reactivity to achieve consistent results.

Nuclear Applications

Tungsten’s density and high melting point make its crucibles suitable for use in nuclear reactors and related research. They are often employed to contain and handle radioactive materials or to fabricate nuclear fuel pellets. The material’s resistance to radiation damage further enhances its suitability for such critical applications.

Aerospace Industry

In aerospace engineering, tungsten crucibles are used to produce high-performance alloys and superalloys needed for turbine blades, rocket nozzles, and spacecraft components. These parts require exceptional strength and resistance to extreme temperatures, which tungsten-based processing equipment helps achieve.

Pharmaceutical and Chemical Industries

Tungsten crucibles are employed in pharmaceutical and chemical research for reactions that require precise temperature control and a chemically inert environment. They facilitate the synthesis of high-purity compounds, including specialty chemicals and advanced materials.

Glass and Ceramic Manufacturing

In the glass and ceramic industries, tungsten crucibles are used for melting and forming high-temperature-resistant materials. Their ability to handle extreme heat without contaminating the molten material ensures the production of high-quality, defect-free products.

Advantages of Using Tungsten Crucibles

Durability and Longevity

Tungsten crucibles are highly durable and capable of withstanding repeated thermal cycling without degradation. This longevity makes them a cost-effective choice for industries that rely on high-temperature processing.

Purity Preservation

The non-reactive nature of tungsten prevents contamination of the materials processed within the crucible. This property is particularly critical in semiconductor and pharmaceutical applications, where material purity is paramount.

Thermal Efficiency

The excellent thermal conductivity of tungsten ensures efficient heat transfer, reducing energy consumption and improving processing efficiency.

Versatility

Tungsten crucibles are compatible with a wide range of materials and processes, making them versatile tools across multiple industries.

Challenges and Limitations

Despite their many advantages, tungsten crucibles also face certain challenges:

Cost: Tungsten is an expensive material, which increases the initial investment required for tungsten crucibles.

Brittleness at Room Temperature: While tungsten exhibits remarkable strength at high temperatures, it can be brittle at lower temperatures, requiring careful handling.

Machining Difficulty: Tungsten’s high density and hardness make it challenging to machine into complex shapes, increasing manufacturing costs and lead times.

Advances in Tungsten Crucible Technology

Continuous advancements in manufacturing techniques have improved the performance and accessibility of tungsten crucibles. Innovations such as powder metallurgy and additive manufacturing enable the production of complex shapes with greater precision and reduced waste. Coatings and composite materials are also being developed to enhance the performance of tungsten crucibles, addressing limitations such as brittleness and oxidation.

Choosing the Right Tungsten Crucible

Selecting the appropriate tungsten crucible for a specific application involves considering factors such as:

Operating Temperature: Ensuring the crucible can withstand the required temperature range.

Material Compatibility: Assessing the potential for chemical reactions between the crucible and the processed material.

Size and Shape: Choosing dimensions that suit the application and equipment.

Cost and Availability: Balancing performance requirements with budget constraints.

Consulting with manufacturers and suppliers can help identify the best crucible for your needs, taking into account these variables.

Maintenance and Care

Proper maintenance is essential to extend the lifespan of tungsten crucibles. Recommendations include:

Avoiding rapid temperature changes to prevent thermal shock.

Cleaning the crucible thoroughly after each use to remove residues.

Storing the crucible in a dry, controlled environment to prevent oxidation.

Inspecting regularly for signs of wear or damage and replacing as necessary.

Conclusion

Tungsten crucibles are indispensable in industries that require high-temperature processing, chemical stability, and durability. Their applications span from semiconductor manufacturing to aerospace engineering, demonstrating their versatility and value. Despite certain challenges, ongoing technological advancements continue to enhance their performance and broaden their utility. For industries seeking reliable and efficient solutions for extreme conditions, tungsten crucibles remain a preferred choice.