Introduction

In the world of advanced ceramics and materials science, few compounds have had as profound an impact as Yttria-Stabilized Zirconia (YSZYSZ Substrates (Yttria-stabilized Zirconia)). This remarkable material, a stabilized form of zirconium dioxide (ZrO₂) doped with yttrium oxide (Y₂O₃), exhibits a unique combination of high ionic conductivity, thermal stability, mechanical strength, and corrosion resistance.

Yttria-Stabilized Zirconia (YSZ) plays an indispensable role across multiple high-tech industries, from solid oxide fuel cells (SOFCs) to oxygen sensors, thermal barrier coatings, and advanced wear-resistant components. In this article, we will explore in depth what YSZ is, its properties, synthesis methods, and where it is applied in modern technology.

As detailed by the U.S. Department of Energy, SOFCs utilizing YSZ electrolytes offer high efficiency and fuel flexibility.

Understanding Yttria-Stabilized Zirconia (YSZ)

What is Zirconia (ZrO₂)?

Zirconia is a white crystalline oxide of zirconium, known for its high melting point (~2,715°C), excellent chemical inertness, and strong mechanical properties. However, pure zirconia undergoes phase transitions between monoclinic, tetragonal, and cubic structures at different temperatures, leading to volume changes that can crack materials during cooling.

According to Britannica, zirconia is widely recognized for its exceptional high-temperature stability and strength.

Why Stabilize Zirconia?

To counteract this structural instability, yttrium oxide (Y₂O₃) is introduced into the zirconia lattice. The yttria ions replace zirconium ions, creating oxygen vacancies that stabilize the tetragonal or cubic phases at room temperature. This stabilization dramatically improves the material’s:

- Mechanical toughness

- Thermal shock resistance

- Ionic conductivity

- Chemical stability

Thus, Yttria-Stabilized Zirconia (YSZ) emerges as a high-performance material ideal for demanding environments.

Types of YSZ

- 3 mol% YSZ: Higher toughness, used in structural ceramics.

- 8 mol% YSZ: High ionic conductivity, preferred for fuel cells and sensors.

- Partially Stabilized Zirconia (PSZ): Combines cubic and tetragonal phases for enhanced toughness.

Phase Transformation and Stability

Stabilized zirconia resists deleterious phase changes during thermal cycling. The transformation toughening mechanism in YSZ contributes to its remarkable resistance to cracking under mechanical stress, making it invaluable for critical structural applications.

Properties of Yttria-Stabilized Zirconia

YSZ offers a unique combination of properties that include:

- High ionic conductivity, essential for electrochemical devices.

- Exceptional thermal stability, able to withstand extremely high temperatures.

- Low thermal conductivity, providing excellent thermal insulation.

- Superior mechanical toughness, resisting crack propagation.

- Chemical inertness, resisting both acidic and alkaline environments.

- Wear resistance, making it suitable for dynamic applications under load.

These exceptional properties position YSZ as a multifunctional material in extreme and specialized environments.

How is YSZ Manufactured?

Solid-State Reaction Method

Mixing ZrO₂ and Y₂O₃ powders followed by high-temperature calcination to form a homogeneous solid solution, often used for bulk material production.

Spray Pyrolysis Method

Atomizing a precursor solution into fine droplets which are then thermally decomposed into ceramic powders, allowing for control over particle size and distribution.

Sol-Gel Processing

Producing highly pure and uniform YSZ powders by hydrolysis and polycondensation of metal alkoxides, offering excellent chemical homogeneity.

Physical Vapor Deposition (PVD)

Depositing thin films of YSZ onto substrates for specialized high-performance applications like coatings and sensors.

Hot Isostatic Pressing (HIP)

Applying heat and isostatic gas pressure simultaneously to achieve near-theoretical density and superior mechanical properties, particularly in large or complex-shaped components.

Each method offers specific advantages depending on the intended application, whether it be bulk ceramic components or thin film coatings.

Major Applications of YSZ

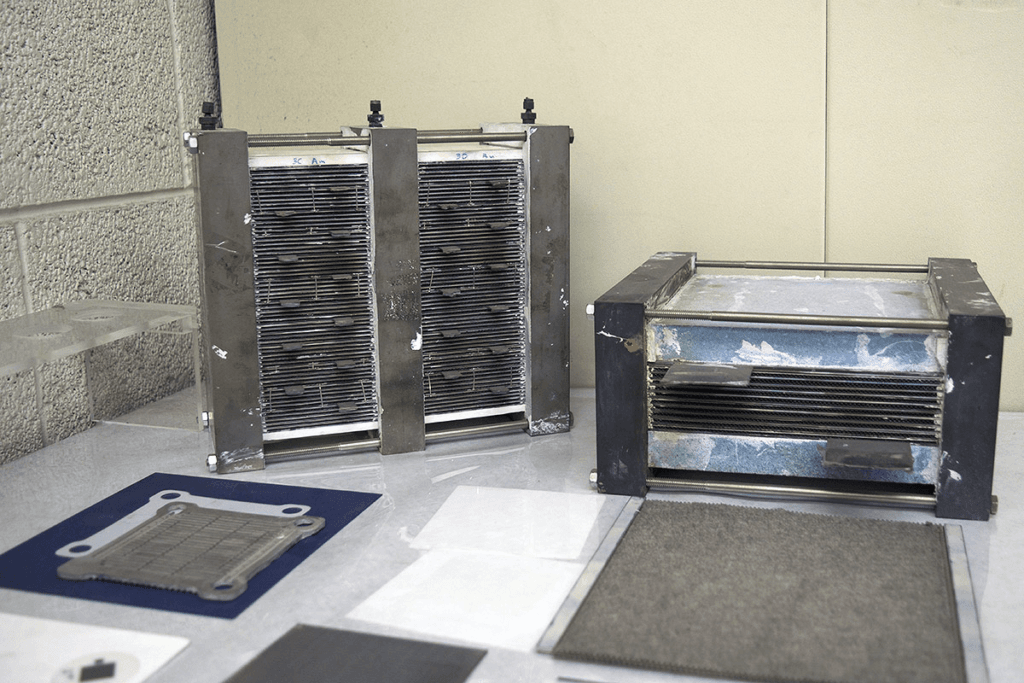

Solid Oxide Fuel Cells (SOFCs)

YSZ serves as the electrolyte material in SOFCs because of its exceptional oxygen ion conductivity at high temperatures (~800–1000°C). Its stability in both oxidizing and reducing environments enables efficient electrochemical reactions for power generation. Efforts to reduce SOFC operating temperatures below 600°C increasingly rely on engineered YSZ composites and thin-film YSZ layers.

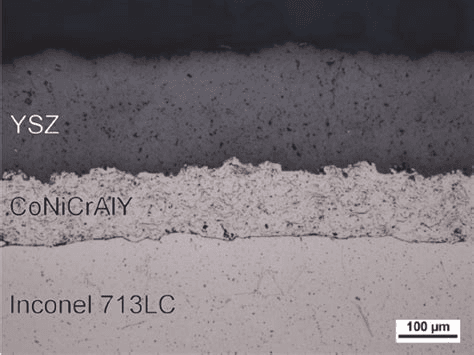

Thermal Barrier Coatings (TBCs)

In aerospace and gas turbine industries, YSZ is used as a protective layer to insulate metal components from extreme temperatures. YSZ coatings reduce metal temperatures by several hundred degrees Celsius, dramatically improving component life and engine efficiency. Advanced multilayer TBC systems often feature YSZ as the topcoat combined with bond coats to manage oxidation.

Oxygen Sensors

YSZ’s ability to conduct oxygen ions underpins its use in oxygen sensors, critical for applications such as automotive emission control and industrial process monitoring. Lambda sensors based on YSZ technology have become essential for maintaining optimal air-fuel ratios in modern internal combustion engines.

Dental and Medical Implants

Due to its excellent biocompatibility, strength, and aesthetics, YSZ is a preferred material for dental crowns, bridges, hip and knee replacement components. High-translucency YSZ variants are now available, offering improved aesthetic results for dental restorations without compromising mechanical strength.

Wear-Resistant Components

Components subjected to intense wear, such as pump seals, cutting tools, and ball bearings, benefit from the hardness and fracture toughness of YSZ. It offers extended service life compared to traditional metals and polymers, particularly in chemically aggressive or high-temperature environments.

Thin Film Applications

YSZ thin films are critical as buffer layers in the epitaxial growth of high-temperature superconductors, integrated circuits, and photovoltaic devices. Their role in preventing lattice mismatch and promoting defect-free crystal growth is essential for device performance.

Catalysis Support

YSZ serves as a catalyst support in automotive catalytic converters and other high-temperature catalytic processes. Its high oxygen ion mobility aids in redox reactions, improving the efficiency and lifetime of catalytic systems.

Structural Characteristics of YSZ

YSZ exhibits a stabilized cubic or tetragonal phase structure, depending on the yttria concentration and thermal history. The stabilized structures allow for:

- Superior phase stability over a broad temperature range.

- Enhanced ionic mobility due to the presence of oxygen vacancies.

- High fracture toughness through stress-induced phase transformation.

- Resistance to microcracking and thermal shock during service.

Electrical Conductivity in YSZ

YSZ is renowned for its high oxygen-ion conductivity, which makes it ideal for use in electrochemical devices like SOFCs and oxygen sensors. The conduction mechanism involves the movement of oxygen ions through the vacancies created by the yttrium doping.

Factors influencing conductivity include:

- Doping level of yttria.

- Grain size and boundary characteristics.

- Temperature of operation.

- Grain boundary effects, which may dominate at lower temperatures.

Optimization of grain size and processing methods continues to enhance the performance of YSZ-based ionic devices.

Mechanical Properties of YSZ

YSZ exhibits remarkable mechanical properties, including:

- High flexural strength (over 1000 MPa in optimized compositions).

- Resistance to crack propagation due to transformation toughening.

- Excellent wear resistance under mechanical and thermal cycling.

- High hardness values (up to 12 GPa), providing durability in abrasive environments.

These properties make YSZ a prime choice for mechanical components in extreme environments.

Thermal Properties of YSZ

YSZ’s low thermal conductivity (~2 W/m·K at 1000°C) makes it an excellent thermal barrier material. This characteristic reduces heat transfer and protects underlying structures from thermal damage, crucial for aerospace, turbine, and high-temperature industrial applications.

YSZ maintains structural integrity even after prolonged thermal cycling, a key requirement for reliable high-temperature coatings.

Chemical Stability and Corrosion Resistance

YSZ offers excellent resistance to a wide range of chemicals, including:

- Strong acids such as sulfuric and hydrochloric acid.

- Alkalis such as sodium hydroxide.

- Oxidizing and reducing atmospheres in combustion or industrial processes.

This chemical inertness extends YSZ’s durability and reliability in chemically aggressive environments, outperforming many traditional ceramic and metallic materials.

Advantages and Limitations of YSZ

Advantages

- Outstanding thermal and chemical stability.

- High ionic conductivity, particularly at elevated temperatures.

- Exceptional mechanical properties for harsh environments.

- Broad range of industrial, medical, and energy-related applications.

- Biocompatibility for use in implants and prosthetics.

- Ease of doping with other rare-earth or transition-metal oxides to tailor properties.

Limitations

- Requires high temperatures to achieve optimal ionic conductivity.

- Higher cost relative to traditional ceramics.

- Potential for low-temperature aging in moisture-rich environments.

- Complex processing requirements for large or intricate components.

Ongoing research is focusing on reducing operating temperatures and improving the long-term stability of YSZ-based systems.

Recent Developments in YSZ Research

- Low-Temperature SOFCs: Developing YSZ composites and doped variants to enable operation at lower temperatures.

- Nano-structured YSZ: Enhancing surface area and conductivity through nanostructuring techniques.

- YSZ Composites: Combining YSZ with other oxides such as scandia or gadolinia to tailor mechanical and ionic properties.

- Advanced Deposition Techniques: Refining methods for applying YSZ coatings with improved microstructure, adhesion, and stress resistance.

These innovations are expanding the scope of YSZ applications, especially in green energy, next-generation electronics, and bioengineering fields.

Conclusion

Yttria-Stabilized Zirconia (YSZ) is a versatile and high-performance material vital to industries ranging from energy and aerospace to healthcare and electronics. Its unique blend of ionic conductivity, mechanical strength, and chemical inertness allows it to thrive in some of the most challenging environments known to modern technology.

As research progresses and applications diversify, YSZ will continue to underpin technological advancements across multiple fields, solidifying its place as one of the most important engineered ceramic materials available today.