Weld fittings are essential components used in piping systems to connect, change direction, branch, or control the flow of fluids and gases. They are designed to provide a secure and permanent connection by welding, which creates a seamless joint capable of withstanding high pressure, temperature, and corrosive environments. Made from a variety of materials such as stainless steel, carbon steel, alloy steel, and other metals, weld fittings are widely used in industries ranging from oil and gas to pharmaceuticals.

Types of Weld Fittings

Weld fittings are categorized based on their function and design. Common types include elbows for changing flow direction, tees for branching flow, reducers for connecting pipes of different diameters, caps for closing pipe ends, and couplings for connecting pipe sections. Each type serves a specific purpose and is chosen based on the system’s design requirements and operational conditions.

Materials Used in Weld Fittings

The choice of material for weld fittings depends on the application and the properties required. Stainless steel is valued for its corrosion resistance and strength, making it ideal for chemical and pharmaceutical industries. Carbon steel offers affordability and strength, widely used in oil and gas. Alloy steel enhances resistance to high temperatures and pressures, while non-ferrous metals like copper and aluminum provide specialized properties such as lightweight construction or electrical conductivity.

Welding Methods for Fittings

Weld fittings are installed using various welding techniques to ensure a strong joint. Butt welding creates seamless connections for high-pressure systems. Socket welding involves inserting the pipe into a recessed area of the fitting before welding, commonly used for smaller-diameter pipes. TIG welding is precise, ideal for thin materials and high-quality applications, while MIG welding offers efficiency for less critical tasks.

Applications of Weld Fittings

Weld fittings find applications across diverse industries due to their versatility and reliability.

Oil and Gas Industry

In the oil and gas sector, weld fittings play a vital role in ensuring safe and efficient transport of crude oil, natural gas, and refined products. They are used in pipelines operating under high pressures and corrosive environments, making them essential for drilling operations, refineries, and petrochemical plants. These fittings also support subsea pipelines and offshore platforms, where reliability is critical.

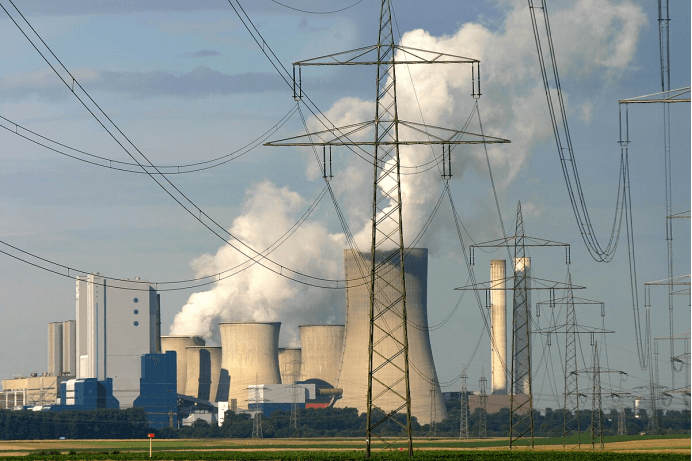

Power Generation

Power plants utilize weld fittings in steam, water, and gas pipelines, particularly in systems like boiler feed water and steam distribution networks. These fittings are engineered to endure the extreme temperatures and pressures typical in power generation, especially in nuclear, coal-fired, and combined-cycle plants. Alloy steel and stainless steel are frequently selected for their heat and corrosion resistance.

Chemical and Petrochemical Industries

Chemical processing plants depend on weld fittings to handle hazardous and corrosive materials. These fittings are integral to systems transporting acids, alkalis, and other reactive chemicals. Stainless steel weld fittings are favored for their durability and ability to maintain system integrity, even under harsh conditions. In petrochemical applications, weld fittings connect reactors, separators, and distillation units, ensuring precise flow control and safety.

Food and Beverage Industry

In food and beverage production, weld fittings are critical for maintaining hygiene and process efficiency. They are used in pipelines transporting liquids, semi-solids, and gases, such as milk in dairy processing or carbon dioxide in beverage carbonation. The smooth, polished surfaces of stainless steel weld fittings help prevent contamination and adhere to stringent sanitary standards.

Pharmaceutical Industry

The pharmaceutical sector relies on high-purity weld fittings to transport sterile and sensitive materials. These fittings are used in pipelines for water-for-injection systems, process gases, and chemical reagents. Polished stainless steel fittings ensure a contaminant-free environment, meeting the rigorous regulatory standards required for drug manufacturing.

Automotive Industry

Weld fittings are integral to the automotive industry, particularly in fluid and gas systems. They are used in fuel lines, brake systems, and exhaust assemblies, where reliability and precision are paramount. The use of advanced alloys in these fittings ensures they can withstand vibration, pressure, and corrosive fuels, contributing to vehicle performance and safety.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems employ weld fittings for the efficient transport of fluids and gases. Whether in residential buildings or large industrial facilities, these fittings help create seamless connections that minimize energy loss and ensure system durability. Weld fittings are commonly found in chillers, boilers, and ductwork.

Water and Wastewater Management

Weld fittings are widely used in municipal water supply and wastewater treatment systems. They provide durable connections in pipelines transporting potable water, sewage, and treated effluents. Carbon steel and ductile iron weld fittings are often chosen for their strength and ability to resist external pressures and corrosive environments. These fittings help reduce leaks and maintain system efficiency.

Aerospace and Defense

The aerospace and defense sectors require weld fittings for critical applications in fuel systems, hydraulic systems, and environmental control systems. Made from specialized alloys, these fittings are designed to function reliably under extreme conditions, including high-altitude pressures, temperature fluctuations, and exposure to corrosive substances. Precision and durability are paramount in these industries.

Mining and Mineral Processing

In mining operations, weld fittings are used in pipelines for slurry transport, chemical handling, and dewatering systems. Their robust construction ensures they can withstand abrasive materials and corrosive chemicals, making them essential for the harsh environments of mineral extraction and processing. These fittings support systems critical to ore transport and refining.

Advantages of Weld Fittings

Weld fittings offer numerous benefits. They provide strength and durability, creating joints stronger than threaded or flanged connections. They ensure leak-proof connections through seamless welding and are available in various shapes, sizes, and materials for versatile applications. These fittings resist extreme pressure and temperature, making them suitable for demanding environments. Corrosion-resistant materials like stainless steel enhance system longevity.

Challenges and Considerations

Despite their advantages, weld fittings come with challenges. Skilled labor is required for high-quality welding. Welded connections must undergo inspection and testing to ensure integrity. Initial costs for weld fittings and installation can be high. Additionally, welded joints are permanent, limiting flexibility for future modifications.

Future Trends in Weld Fittings

The demand for weld fittings continues to grow as industries expand. Emerging trends include advanced materials with enhanced properties, robotic welding systems for precision, sustainable manufacturing processes, and custom fittings tailored to specific applications.

Conclusion

Weld fittings are indispensable components in modern piping systems, offering strength, durability, and reliability across a wide range of industries. From oil and gas pipelines to pharmaceutical manufacturing, their applications are vast and varied. Despite challenges such as the need for skilled labor and higher initial costs, the advantages of weld fittings make them a critical choice for systems requiring robust and leak-proof connections. With ongoing advancements in materials and technology, weld fittings will continue to play a vital role in industrial and commercial applications.