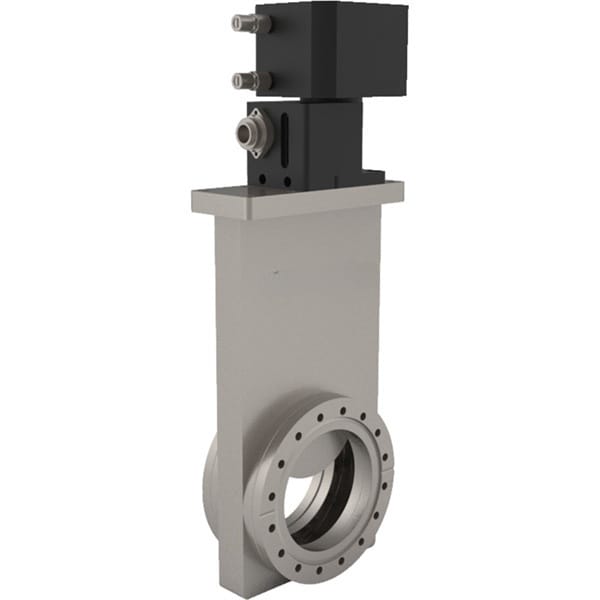

TFM’s Stainless Steel Standard Gate Valves

TFM’s stainless steel standard gate valves are reliable and economical, designed as general-purpose components for high vacuum (HV) applications that demand cleanliness and resistance to corrosion.

Key Features

- Electropolished Stainless Steel Construction: Made from high-quality electropolished stainless steel, these valves ensure durability and cleanliness, making them ideal for sensitive environments.

- Compact Design with High Conductance: These valves provide excellent conductance while maintaining a compact footprint, ensuring efficient flow control in various applications.

- Smooth and Shock-Free Operation: Engineered to minimize vibration, TFM’s gate valves ensure smooth operation, reducing the risk of disruptions in sensitive processes.

- Versatile Operation Options: Available in both manual and pneumatic configurations, these valves can be tailored to meet the specific requirements of your system.

- Safety Features: The pneumatic valves are designed to remain closed during power loss or a drop in air pressure, enhancing safety and reliability in critical applications.

- Visual LED Position Indicators: Equipped with visual LED indicators, these valves provide clear feedback on their position for easier monitoring and operation.

- Pneumatic Models Requirements: Note that pneumatic models require a solenoid kit, sold separately, to ensure proper functionality.

Specifications Table

| Manufacturer | TFM |

|---|---|

| Pressure | Torr Min: 7.500 x 10-9 Torr Max: 760 Torrmbar Min: 1.000 x 10-8 mbar Max: 1013 mbar |

| Rates | Helium Leak Rate 1.000 x 10-9 mbar*L/s 7.520 x 10-10 Torr*L/s |

| Temperature | Actuator 60.0 ºC 140 ºFBakeable 120 ºC 248 ºF |

| Shaft Seal Material | Bellows Sealed |

| Cycle Life | 10,000 |

| Actuator Type | Pneumatic Double Acting |

| Solenoid Kit Included | No |

| Position Indicators | Yes |

| Max Differential Pressure Before Open | 22.5 Torr |

| Bonnet Seal Type | Fluorocarbon (FKM) |

| Valve Body Material | Stainless Steel |

| Valve Seal Material | Fluorocarbon (FKM) |

Reviews

There are no reviews yet.