Introduction

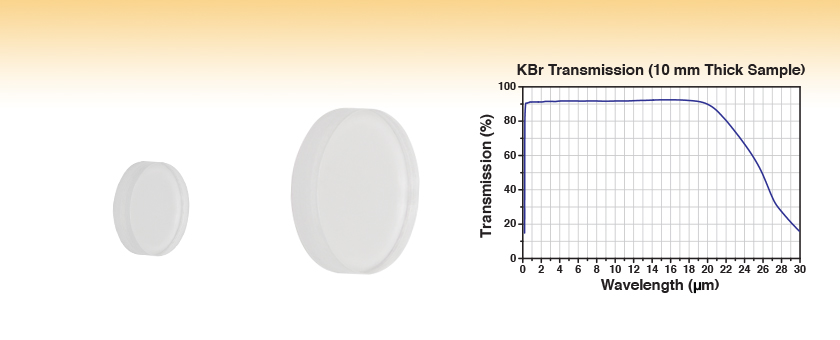

Potassium Bromide (KBr) is one of the most widely used optical materials for infrared research, spectroscopy, and thin film applications. As a crystalline alkali halide compound, KBr offers exceptional transmission across a broad infrared spectrum, very low optical absorption, and a chemically stable lattice structure that makes it suitable for high-precision scientific and industrial environments.

Within the thin film community, KBr provides a dependable substrate for evaporation, organic film deposition, cryogenic studies, and infrared optical system development. Thin Film Materials (TFM) supplies KBr substrates manufactured with laboratory-grade precision, excellent flatness, and superior surface quality, ensuring reproducible performance for advanced applications.

Material Properties of Potassium Bromide (KBr)

Optical Transmission Range

KBr offers outstanding transparency from 0.2 μm to 25–30 μm, covering the near-IR, mid-IR, far-IR, and part of the UV spectrum. This rare transmission range is one of the primary reasons KBr remains indispensable for IR-related research and instrumentation.

Chemical Inertness

KBr is chemically stable in the presence of oils, many organic solvents, and most weak acids and bases. While hygroscopic, its crystal structure remains stable under controlled humidity conditions, making it ideal for sealed or dry environments.

Low Background Signal

KBr’s minimal IR absorption ensures extremely low spectral background noise, essential for sensitive spectroscopic measurements, thin film analysis, and molecular vibration studies.

Surface Quality and Fabrication

KBr can be polished into high-accuracy windows, plates, circular substrates, and custom wafers. Its machinability allows fabrication into optical-grade surfaces suitable for infrared imaging, sensing, and thin film deposition.

Applications in Infrared Spectroscopy

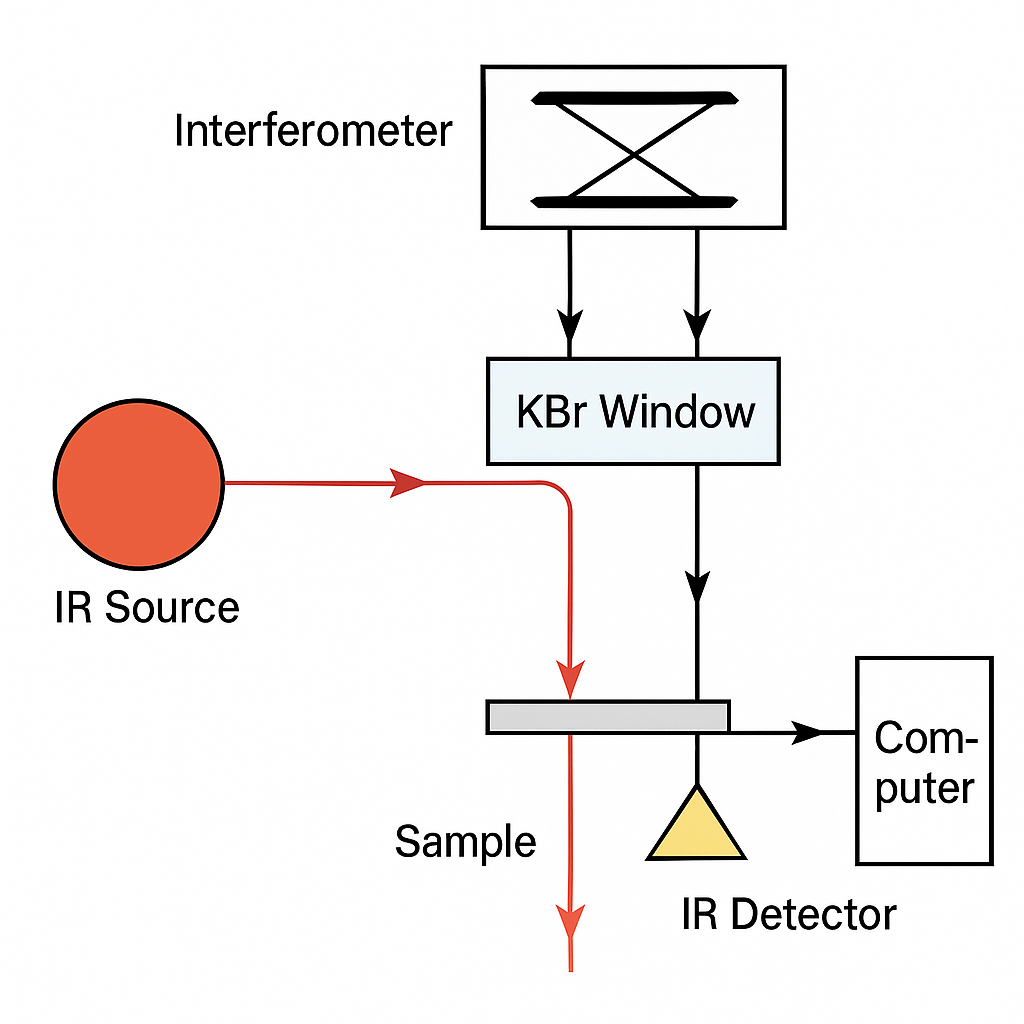

FTIR Spectroscopy

KBr plays a fundamental role in FTIR as:

- Sample windows

- Transmission substrates

- Beamline optical elements

- Carriers for pressed-pellet preparations

It supports a broad range of analytical tasks such as:

- Functional group identification in organic chemistry

- Polymer and elastomer characterization

- Pharmaceutical ingredient verification

- Environmental contaminant detection

- Fuel and lubricant analysis

KBr Pellets for Solid Sample Preparation

Ground KBr mixed with samples and pressed into transparent pellets is a standard FTIR method. Industries relying on this technique include pharmaceuticals, petrochemicals, plastics, forensics, and environmental labs.

IR Windows in Spectrometer Beam Paths

KBr windows are used for:

- Reaction chamber monitoring

- Gas-phase analysis

- Sealed optical cells

- Infrared imaging calibration

Their low interference ensures high-fidelity IR measurements.

KBr Substrates in Thin Film Research and Deposition

Thin Film Absorption and Transmission Studies

KBr’s near-ideal IR baseline enables:

- Study of IR-active phonon modes

- Analysis of organic and polymer thin films

- Semiconductor absorption behavior

- Nanomaterial optical characterizations

Organic Films and Low-Temperature Deposition

KBr substrates support:

- Molecular beam epitaxy of organic materials

- Cryogenic thin film growth

- Deposition of biomolecules

- Polymer coating analysis

Its chemical neutrality ensures that deposited films exhibit undistorted spectral features.

Vacuum Evaporation and PVD

KBr is widely used in:

- Thermal evaporation

- Low-temperature physical vapor deposition

- Laser-assisted thin film formation

A unique advantage is that deposited films can be lifted off by dissolving KBr in water, allowing researchers to transfer films to other substrates for further testing.

Quantum Materials and 2D Materials

KBr supports emerging research in:

- Van der Waals materials

- Terahertz and phonon-based materials

- Excitonic and IR quantum materials

- 2D thin film systems

Its broad IR transparency allows direct study of low-energy excitations.

Applications in Biomedical and Life Sciences

FTIR-Based Pathology and Diagnostics

KBr is used in:

- Cell and tissue IR analysis

- Serum and biofluid fingerprinting

- Disease marker detection

- Molecular structural studies

FTIR-based diagnostics increasingly rely on KBr substrates due to their stability and spectral clarity.

Infrared Biosensors

KBr substrates support biosensor development involving:

- Proteins and enzymes

- Viral and bacterial components

- Biomolecule interactions

- Bio-surface adsorption studies

Pharmaceutical Characterization

Pharmaceutical research uses KBr for:

- Studying polymorphs

- Identifying APIs

- Investigating excipient interactions

- Monitoring solid-state transitions

Industrial and Manufacturing Applications

Polymer and Plastic Manufacturing

KBr enables IR characterization of:

- Polymeric films

- Elastomers

- Additives and fillers

- Coatings and packaging materials

Petrochemical Analysis

KBr substrates are widely used for:

- Lubricants and engine oils

- Fuels and combustion byproducts

- Chemical feedstocks

- Process control monitoring

Environmental and Air Quality Testing

KBr supports environmental IR analysis for:

- Particulate matter

- Airborne pollutants

- Greenhouse gases

- Combustion aerosols

Optical and Instrument Manufacturing

Infrared Instrument Components

KBr is used in:

- IR spectrometer optics

- Beam splitters

- Calibration windows

- Protective IR barriers

- Flow-cell assemblies

Infrared Imaging and Sensing

KBr’s broad transmission makes it ideal for specialized IR imaging, thermal sensing, and metrology systems.

Emerging and Specialized Applications

Mid-IR and Tunable Laser Optics

KBr is compatible with:

- Mid-infrared tunable lasers

- Quantum cascade lasers

- IR nonlinear optics

Terahertz Research

KBr exhibits useful transmission into the THz region, enabling:

- Terahertz spectroscopy

- Low-frequency phonon research

- IR-to-THz hybrid systems

Surface Science and Electrochemistry

KBr provides an optically transparent base for:

- Adsorbed molecular layers

- Chemical reaction monitoring

- Modified thin film surfaces

Storage, Handling, and Operational Considerations

Moisture Sensitivity

KBr is hygroscopic and requires:

- Dry nitrogen cabinets

- Vacuum-sealed packaging

- Low-humidity environments

Handling Methods

Operators should use:

- Gloves

- Dry tweezers

- Clean dry workstations

Cleaning Guidelines

KBr must not be cleaned with water. Only anhydrous solvents are suitable.

Why KBr Substrates Remain Indispensable

KBr continues to outperform alternatives due to:

- Exceptional infrared transparency

- Minimal spectral interference

- Broad compatibility with organic, inorganic, and biological materials

- Transferable thin film deposition capability

- High-accuracy surface finishing

- Reliability across spectroscopy and thin film research

While CaF₂, BaF₂, ZnSe, and Ge have their advantages, KBr remains the first choice for FTIR and IR-intensive applications.

Conclusion

Potassium Bromide (KBr) Substrates play a foundational role in spectroscopy, thin-film research, biomedical diagnostics, environmental analysis, petrochemical testing, polymer science, and optical instrumentation. With unmatched IR transparency and minimal background interference, KBr continues to enable precise and high-quality scientific analysis.

TFM provides precision-polished KBr substrates suitable for R&D laboratories, advanced manufacturing, and specialized optical systems. For specifications or custom sizes, please contact:

Related Products

Potassium Bromide Substrate (KBr)