Vanadium Sputtering Target Description

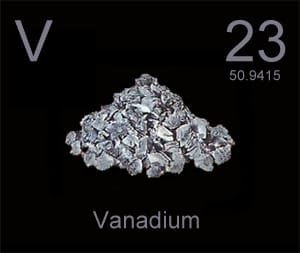

The vanadium sputtering target shares properties with its source material. Vanadium is a hard, silvery-grey, malleable transition metal that naturally occurs in about 65 minerals and fossil fuel deposits. It is primarily produced in China and Russia from steel smelter slag, while other countries obtain it from magnetite directly, flue dust of heavy oil, or as a byproduct of uranium mining. Vanadium is mainly used to produce specialty steel alloys such as high-speed tool steels. The most important industrial vanadium compound, vanadium pentoxide, is used as a catalyst for the production of sulfuric acid. Additionally, the vanadium redox battery for energy storage may become an important application in the future.

The vanadium sputtering target shares properties with its source material. Vanadium is a hard, silvery-grey, malleable transition metal that naturally occurs in about 65 minerals and fossil fuel deposits. It is primarily produced in China and Russia from steel smelter slag, while other countries obtain it from magnetite directly, flue dust of heavy oil, or as a byproduct of uranium mining. Vanadium is mainly used to produce specialty steel alloys such as high-speed tool steels. The most important industrial vanadium compound, vanadium pentoxide, is used as a catalyst for the production of sulfuric acid. Additionally, the vanadium redox battery for energy storage may become an important application in the future.

Vanadium Sputtering Target Specification

| Material Type | Vanadium |

| Symbol | V |

| Color/Appearance | Silvery Gray Metallic |

| Melting Point | 1,890°C |

| Sputter | DC |

| Density | 6.11 g/cc |

| Thermal Conductivity | 30.7 W/m.K |

| Type of Bond | Wets Mo. E-beam-evaporated films preferred. |

| Target Dimensions & Thickness | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Vanadium Sputtering Target Application

Standard vanadium sputtering materials are used for various thin-film coating applications, including CD-ROMs, decoration, flat panel displays, functional coatings, and other optical information storage industries. They are also used in the glass coating industry for car glass and architectural glass, as well as in optical communications. Vanadium is primarily used in alloys, especially with steel. Approximately 85% of all vanadium produced is used in steel, 10% in titanium alloys, and 5% in other applications.

Vanadium Sputtering Target Bonding Service

Specialized bonding services for Vanadium Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Packaging

Our high-purity vanadium sputter targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation, preserving the quality and integrity of our products.

Reviews

There are no reviews yet.