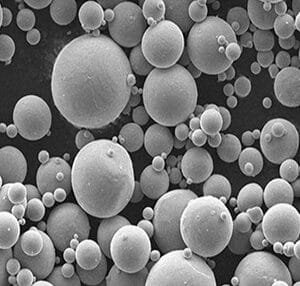

Rene 95 Alloy Powder Overview

Rene 95 Alloy is a high-performance, nickel-based alloy renowned for its ability to endure extreme temperatures and stresses. This age-hardenable alloy can withstand temperatures up to 1400℉, making it one of the most robust options available in its category. It is primarily utilized in gas turbines, specifically for the high-temperature sections.

TFM is a leading global provider of Rene 95 Alloy Powder, bringing over 20 years of expertise in the production and distribution of this high-quality material.

Specifications of Rene 95 Alloy Powder

| Product Name | Rene 95 Alloy Powder |

| Alloy Grade | FGH 4095 |

| Related Grades | Rene 95 |

| Composition | C 0.04-0.09 Cr 12-14 Co 7-9 W 3.3-3.7 Mo 3.3-3.7 Al 3.3-3.7 Ti 2.3-2.7 Fe 0.5max Ni BalNb 3.3-3.7 Ta 0.02max B 0.006-0.015 Zr 0.03-0.07 Si 0.2max Mn 0.15max P 0.015max S 0.015max1 |

| Size Grades | -105+45micron -53+15micron |

| ASTM | / |

| AMS Specification | / |

Applications of Rene 95 Alloy Powder

Cold Working

Rene 95 Alloy Powder can be processed using standard tooling techniques. For optimal results, it is recommended to use soft die materials and heavy-duty lubricants to reduce galling during the cold working process.

Welding

This alloy is weldable using common techniques. It is important to use an appropriate alloy filler metal. Recommended welding methods include submerged-arc welding, gas-tungsten-arc welding, gas metal-arc welding, and shielded metal-arc welding.

Forming

Rene 95 Alloy Powder can be formed using standard techniques. Despite its good ductility, it requires robust equipment due to its high strength compared to conventional steel.

Machinability

The alloy can be machined using conventional methods. It exhibits higher strength and work-hardening properties, which can impact machinability. Water-based coolants are recommended for milling, turning, or grinding, while heavy lubricants are preferred for boring, drilling, broaching, or tapping. To minimize work-hardening effects and chatter, use appropriate tooling and heavy-duty machining equipment.

Reviews

There are no reviews yet.