Introduction

Chromium powder is a strategically important metallic material widely used across surface engineering, advanced manufacturing, energy systems, electronics, and high-temperature industrial processes. Owing to its excellent corrosion resistance, high melting point, strong affinity for oxygen, nitrogen, and carbon, and its ability to form stable oxides and carbides, chromium plays a unique and often irreplaceable role in both traditional industries and cutting-edge technologies.

In powder form, chromium offers enhanced reactivity, precise compositional control, and compatibility with modern powder-based manufacturing methods such as thermal spraying, powder metallurgy, and additive manufacturing. These advantages have significantly expanded its usage scenarios beyond bulk alloys or electroplated chromium layers.

This article provides a systematic and in-depth analysis of chromium powder application scenarios, focusing on why chromium powder is selected, how it performs in different environments, and what technical value it brings to each field.

Fundamental Material Characteristics Relevant to Applications

Before discussing application scenarios, it is essential to understand the intrinsic material properties that define chromium powder’s industrial value:

- High melting point (~1907 °C), suitable for extreme thermal environments

- Outstanding corrosion and oxidation resistance, especially via Cr₂O₃ passivation

- High hardness and wear resistance when used in coatings or alloys

- Strong chemical activity in powder form, enabling solid-state reactions

- Good compatibility with alloy systems (Fe-Cr, Ni-Cr, Co-Cr, etc.)

These characteristics directly determine where chromium powder excels and where it outperforms alternative metallic powders.

Surface Engineering and Protective Coatings

Thermal Spray Coatings

One of the most established uses of chromium powder is in thermal spray technologies, including plasma spraying, HVOF (High-Velocity Oxygen Fuel), and detonation spraying.

Chromium-based coatings are widely used to:

Enhance wear resistance

Improve corrosion protection in harsh chemical environments

Provide high-temperature oxidation resistance

In particular, chromium powder is frequently blended or pre-alloyed to form:

Chromium oxide (Cr₂O₃) ceramic coatings

Chromium-containing metal or cermet coatings

These coatings are common in:

Hydraulic rods and cylinders

Pump shafts and valve components

Paper and printing rolls

Chemical processing equipment

Compared with traditional hard chrome electroplating, chromium powder-based thermal spray coatings avoid hexavalent chromium processes, offering a more environmentally acceptable solution while delivering superior thickness and durability.

Diffusion and Pack Cementation Coatings

Chromium powder is also used in chromizing processes, where chromium diffuses into steel or alloy substrates at elevated temperatures.

Application scenarios include:

- Heat exchanger tubes

- Furnace components

- Petrochemical reactor internals

Chromized layers formed using chromium powder exhibit:

- Excellent sulfidation and carburization resistance

- Improved lifespan in high-temperature corrosive atmospheres

This application remains critical in industries where component replacement costs are extremely high.

Powder Metallurgy and Alloy Manufacturing

Chromium Powder in Steel and Superalloy Production

Chromium is a cornerstone element in stainless steels and high-performance alloys. Chromium powder plays an important role in powder metallurgy routes where precise control of alloy composition is required.

Typical scenarios include:

- Stainless steel PM parts

- Tool steels with enhanced wear resistance

- Iron-chromium magnetic or structural materials

Powder-based chromium addition allows:

- Homogeneous microstructure

- Reduced segregation compared to ingot metallurgy

- Tailored chromium distribution at grain boundaries

This is especially important for sintered components used in automotive, aerospace, and industrial machinery.

Master Alloys and Reactive Sintering

Chromium powder is often used in:

- Chromium master alloys

- Reactive sintering systems to form carbides or nitrides

For example:

- Chromium + carbon → chromium carbides (Cr₃C₂, Cr₇C₃)

- Chromium + nitrogen → chromium nitrides

These reaction-formed phases are critical in wear-resistant composites, cutting tools, and protective coatings.

Energy, High-Temperature, and Chemical Industries

High-Temperature Structural Components

In energy generation and thermal processing industries, chromium powder supports the production of materials capable of long-term service at elevated temperatures.

Key applications include:

- Gas turbine components

- Industrial furnace fixtures

- Heat-resistant alloys for power plants

Chromium’s ability to form a stable oxide layer significantly slows oxidation and material degradation under cyclic thermal loading.

Chemical Processing and Corrosion-Resistant Systems

Chromium powder is indirectly or directly involved in manufacturing materials used in:

- Acidic and alkaline processing environments

- Chloride-containing chemical systems

- High-pressure reactors

Chromium-rich alloys and coatings fabricated using chromium powder offer strong resistance to pitting and crevice corrosion, particularly where nickel-based systems alone are insufficient or cost-prohibitive.

Electronics, Thin Films, and Functional Materials

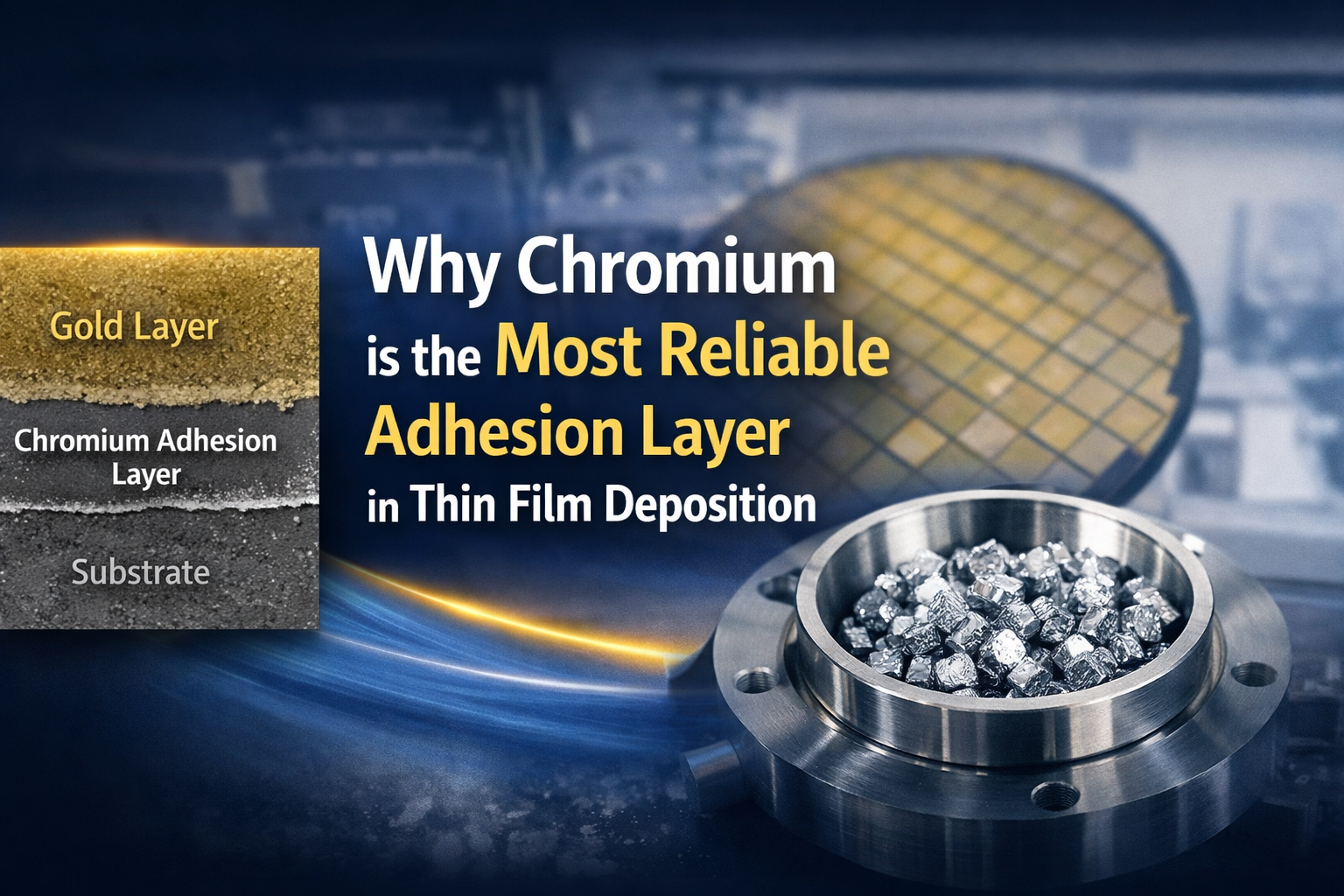

Thin Film Deposition and Sputtering-Related Uses

Although chromium powder itself is not typically used directly in sputtering systems, it is an essential feedstock material for:

- Chromium sputtering targets

- Chromium alloy targets

Chromium thin films deposited from these targets are widely used for:

- Adhesion layers in microelectronics

- Diffusion barriers

- Decorative and functional coatings

The powder’s purity, particle size distribution, and oxygen content directly influence target density and film performance.

Electrical and Magnetic Applications

Chromium powder finds niche usage in:

- Resistor materials

- Magnetic alloy systems (Fe-Cr based)

- EMI shielding and conductive composites

Its controlled oxidation behavior enables stable electrical performance over a wide temperature range, making it suitable for demanding electronic environments.

Additive Manufacturing and Advanced Fabrication

Metal Additive Manufacturing (AM)

With the rapid growth of metal additive manufacturing, chromium powder is increasingly studied and applied as:

- A standalone material for research

- An alloying component in AM feedstocks

In laser powder bed fusion (LPBF) and directed energy deposition (DED), chromium contributes to:

- Improved oxidation resistance of printed parts

- Enhanced high-temperature mechanical stability

However, due to chromium’s high melting point and oxidation sensitivity, powder morphology, flowability, and surface chemistry must be carefully controlled.

Functionally Graded Materials (FGMs)

Chromium powder enables the design of functionally graded structures where:

- Chromium-rich layers provide surface protection

- Core materials maintain toughness or thermal conductivity

Such designs are increasingly relevant in aerospace and advanced tooling applications.

Research, Development, and Emerging Technologies

Catalysis and Chemical Research

Chromium powder is widely used in laboratory research for:

- Catalyst precursor synthesis

- Model reactions in surface chemistry

- Oxidation-reduction studies

Its predictable oxidation states and surface behavior make it valuable in both academic and industrial R&D environments.

Environmental and Replacement Technologies

With global restrictions on hexavalent chromium plating, chromium powder-based technologies are gaining momentum as safer alternatives.

Application trends include:

- Replacement of hard chrome plating

- Development of chromium-based cermet coatings

- Hybrid chromium-oxide protective systems

These developments are expected to expand chromium powder demand in regulated markets.

Key Considerations When Selecting Chromium Powder

When evaluating chromium powder for specific applications, engineers and researchers typically focus on:

- Purity level (industrial vs research grade)

- Particle size and distribution

- Surface oxygen content

- Powder morphology (spherical vs irregular)

- Handling and storage conditions

Each parameter directly influences performance, especially in sintering, spraying, or reactive processing scenarios.

Conclusion

Chromium powder is far more than a simple metallic raw material. Its unique combination of chemical stability, mechanical strength, and high-temperature performance makes it indispensable across surface engineering, powder metallurgy, energy systems, electronics, and advanced manufacturing technologies.

From traditional wear-resistant coatings to emerging additive manufacturing and environmentally compliant alternatives to electroplating, chromium powder continues to evolve in both application breadth and technical sophistication. As industries demand materials that perform reliably under harsher conditions while meeting stricter environmental standards, chromium powder will remain a critical enabler of next-generation material solutions.

For detailed specifications, customized particle sizes, and application-specific guidance, professional material suppliers can provide tailored chromium powder solutions to meet both industrial and research requirements.