Introduction

Aluminum Oxide Sputtering Target (Al₂O₃) is a key ceramic material widely used for forming dense, uniform, and electrically insulating thin films in semiconductor, optical, and protective coating applications. Its stability, compatibility with RF sputtering, and ability to generate high-quality dielectric layers make it essential for research laboratories and industrial thin-film production lines.

Detailed Description

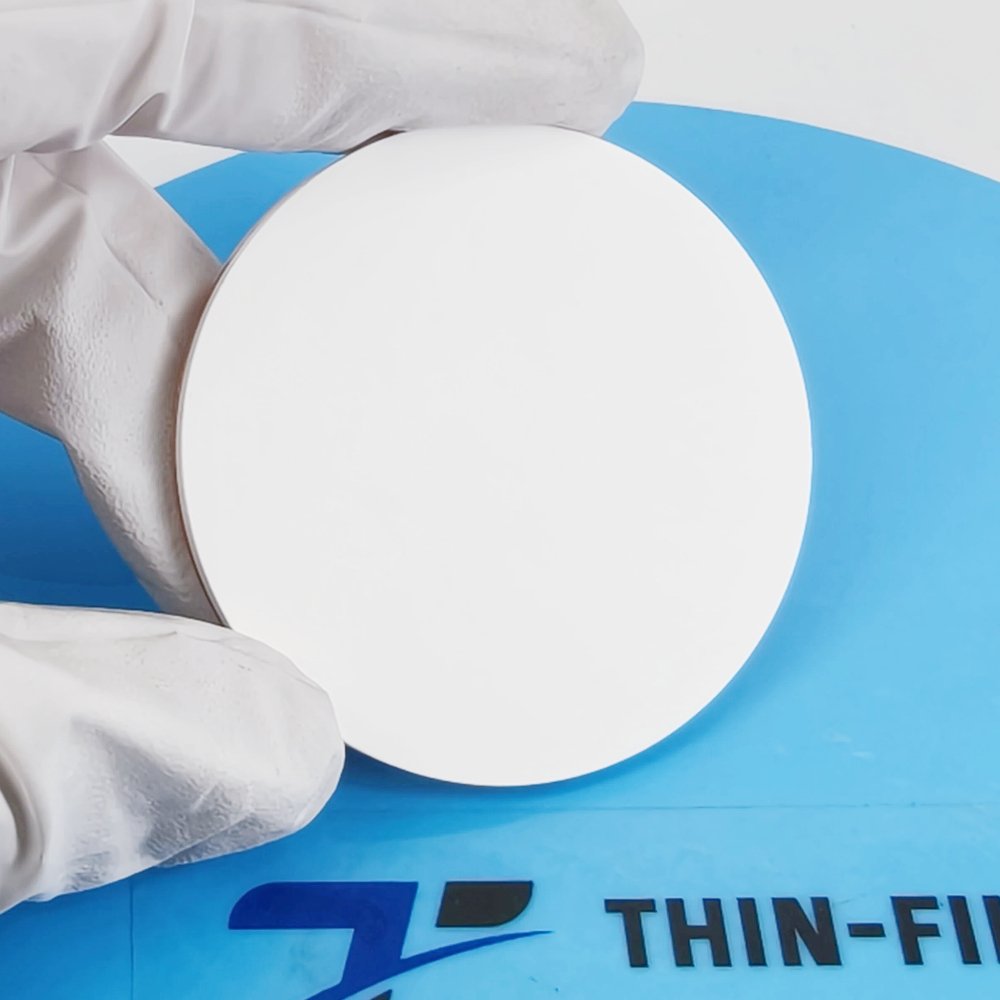

Al₂O₃ sputtering targets are produced through high-temperature sintering or hot-pressing techniques to achieve near-theoretical density and a fine, uniform microstructure. High density is crucial for ensuring consistent sputtering rates, minimizing particle generation, and maintaining uniform erosion across the target surface.

Purity levels typically range from 99.9% to 99.99%, and selecting the appropriate purity depends on the required film properties. High-purity Al₂O₃ minimizes unwanted ionic contaminants that can influence dielectric strength, optical transparency, or adhesion in functional coatings.

Target sizes are fully customizable, from 1” circular pieces to large rectangular plates used in architectural glass coatings. Bonding options such as indium, elastomer, or Cu/Ti backing plates help improve heat dissipation and mechanical stability during high-power sputtering operations.

Applications

Aluminum Oxide Sputtering Targets are used widely in:

Semiconductors & Microelectronics

• Gate dielectrics, insulating layers, passivation coatingsOptical Coatings

• Anti-reflection films, protective layers for lenses and IR windowsDisplay Manufacturing

• TFT dielectric layers, transparent coatingsWear-Resistant & Protective Films

• Hard, stable coatings for industrial and aerospace componentsEnergy & Storage Devices

• Barrier layers and protective coatings in lithium batteries and solid-state devicesR&D and Advanced Material Engineering

• Photonics, microfabrication, sensor development, and thin-film ceramics research

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | Higher purity improves dielectric strength and reduces contaminants |

| Diameter | 25 – 300 mm (custom) | Matches most RF and magnetron sputtering systems |

| Thickness | 3 – 10 mm | Affects sputtering lifetime and target strength |

| Density | 3.85 – 3.95 g/cm³ | Higher density improves film uniformity & reduces cracking |

| Bonding | Indium / Elastomer / Cu or Ti back plate | Enhances heat transfer and deposition stability |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Al₂O₃ | Excellent dielectric strength & chemical resistance | Semiconductors, optical coatings |

| SiO₂ | Low refractive index, high transparency | Optical layers & insulation |

| MgO | High thermal conductivity & good adhesion | Superconductor and protective films |

FAQ

| Question | Answer |

|---|---|

| Can the product be customized? | Yes. Purity, size, thickness, bonding, and geometry can all be customized. |

| How is it packaged? | Vacuum-sealed with foam protection, placed in export-safe cartons or wooden crates. |

| Which industries use it most? | Semiconductor, optics, aerospace, display manufacturing, and energy storage. |

| Do you offer bonding services? | Yes, including indium bonding, elastomer bonding, and Cu/Ti backing plates. |

| Is Al₂O₃ suitable for RF sputtering? | Yes. Due to its insulating nature, it is widely used in RF sputtering systems. |

Packaging

Each Aluminum Oxide Sputtering Target is vacuum-sealed to prevent contamination and moisture absorption. External labeling ensures easy identification, and targets are protected with foam cushioning and sturdy export packaging to prevent damage in transit.

Conclusion

Al₂O₃ sputtering targets deliver reliable performance, excellent dielectric properties, and exceptional chemical durability, making them ideal for advanced thin-film deposition in semiconductor, optical, and protective applications. Custom design, consistent quality, and reliable delivery ensure that these targets meet the demanding requirements of research institutions and industrial production environments.

For detailed specifications or a quotation, please contact us at:

📩 sales@thinfilmmaterials.com

Reviews

There are no reviews yet.