Aluminum Sputtering Target Description

Element Aluminum

Element Aluminum Bauxit

BauxitAluminum sputtering targets share the same properties as metallic aluminum, a silvery-white, soft, non-magnetic, and ductile metal. Aluminum constitutes about 8% of the Earth’s crust, making it the third most abundant element after oxygen and silicon. Although aluminum is the most plentiful metal in the crust, it is rare in pure form due to its high reactivity.

Aluminum is typically found in over 270 minerals, with bauxite being the primary ore, consisting mainly of hydrated alumina and varying amounts of iron oxides. Aluminum layers are used for reflective coatings in telescopes, automotive headlamps, mirrors, packages, and toys. Aluminum sputtering targets and evaporation materials are extensively utilized in aerospace, automotive lighting, OLED, and optical industries.

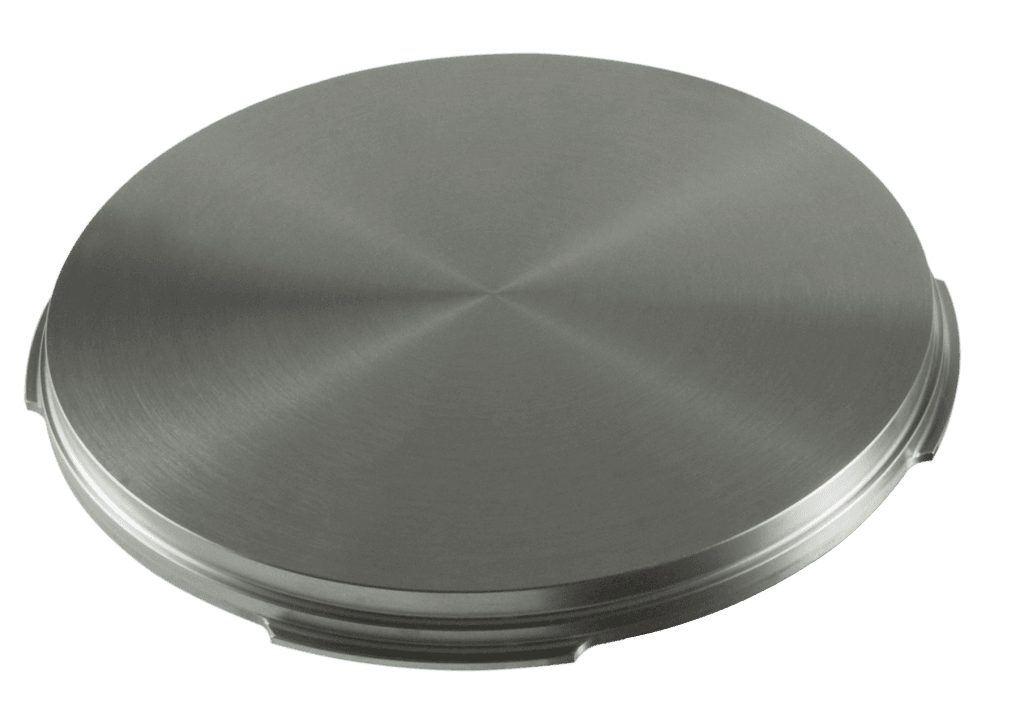

Aluminum Sputtering Target Specification

| Material Type | Aluminum |

| Symbol | Al |

| Color/Appearance | Silvery, Metallic |

| Melting Point | 660°C |

| Density | 2700 kg/m3 |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Alloys W/Mo/Ta. Flash evap or use BN crucible |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Aluminum Sputtering Target Application

Aluminum, known for its excellent thermal properties, is both malleable and ductile. Aluminum and its alloys are commonly used in aircraft assemblies and engine components. The aluminum sputtering target is utilized for thin film deposition in applications such as fuel cells, decorative coatings, semiconductors, displays, LEDs, photovoltaic devices, and glass coatings.

Aluminum Sputtering Target Bonding Services

Specialized bonding services for Aluminum Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Aluminum Sputtering Target Manufacturing processes

Production and purification of aluminum

Deformation treatment of aluminum sputtering target

High-purity aluminum ingots are forged, rolled, and heated to refine the crystal grains and increase density, meeting the standards for aluminum sputtering targets. The processed aluminum material is then shaped into the specific target size needed for vacuum coating, requiring high precision and superior surface quality.

Aluminum Sputtering Target Packing

Our Aluminum Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation.

Get Contact

TFM offers Aluminum Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.