Barium Titanate Sputtering Target Description

The Barium Titanate Sputtering Target from TFM is an oxide sputtering material with the chemical formula BaTiO3.

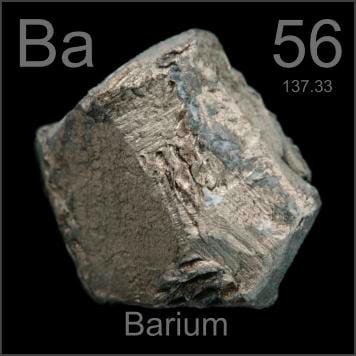

Barium is the fifth element in group 2 and is a soft, silvery alkaline earth metal. Because of its high chemical reactivity, barium is never found in nature as a free element. Its hydroxide, known in pre-modern times as baryta, does not occur as a mineral, but can be prepared by heating barium carbonate. The most common naturally occurring minerals of barium are barite (barium sulfate, BaSO4) and witherite (barium carbonate, BaCO3), both insoluble in water. The name barium originates from the alchemical derivative “baryta”, from Greek βαρύς (barys), meaning “heavy.”

Barium is the fifth element in group 2 and is a soft, silvery alkaline earth metal. Because of its high chemical reactivity, barium is never found in nature as a free element. Its hydroxide, known in pre-modern times as baryta, does not occur as a mineral, but can be prepared by heating barium carbonate. The most common naturally occurring minerals of barium are barite (barium sulfate, BaSO4) and witherite (barium carbonate, BaCO3), both insoluble in water. The name barium originates from the alchemical derivative “baryta”, from Greek βαρύς (barys), meaning “heavy.”

Related Product: Barium (Ba) Sputtering Target

Titanium is a chemical element that originated from Titans, the sons of the Earth goddess of Greek mythology. It was first mentioned in 1791 and observed by W. Gregor. The isolation was later accomplished and announced by J. Berzelius. “Ti” is the canonical chemical symbol of titanium. Its atomic number in the periodic table of elements is 22 with a location at Period 4 and Group 4, belonging to the d-block. The relative atomic mass of titanium is 47.867(1) Dalton, the number in the brackets indicating the uncertainty.

Titanium is a chemical element that originated from Titans, the sons of the Earth goddess of Greek mythology. It was first mentioned in 1791 and observed by W. Gregor. The isolation was later accomplished and announced by J. Berzelius. “Ti” is the canonical chemical symbol of titanium. Its atomic number in the periodic table of elements is 22 with a location at Period 4 and Group 4, belonging to the d-block. The relative atomic mass of titanium is 47.867(1) Dalton, the number in the brackets indicating the uncertainty.

Related Product: Titanium (Ti) Sputtering Target

Oxygen is a chemical element named from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first mentioned and observed by W. Scheele in 1771, who also later accomplished and announced its isolation. The chemical symbol for oxygen is “O,” and it has an atomic number of 8. Oxygen is located in Period 2, Group 16 of the periodic table, within the p-block. Its relative atomic mass is 15.9994(3) Dalton, with the number in parentheses indicating the measurement’s uncertainty.

Oxygen is a chemical element named from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first mentioned and observed by W. Scheele in 1771, who also later accomplished and announced its isolation. The chemical symbol for oxygen is “O,” and it has an atomic number of 8. Oxygen is located in Period 2, Group 16 of the periodic table, within the p-block. Its relative atomic mass is 15.9994(3) Dalton, with the number in parentheses indicating the measurement’s uncertainty.

Barium Titanate Sputtering Target Handling Notes

1. Elastomer bonding is recommended for BaTiO3 sputtering targets due to their brittleness and low thermal conductivity, which make them less suitable for traditional sputtering methods.

2. This material has low thermal conductivity and is susceptible to thermal shock.

Barium Titanate Sputtering Target Application

The Barium Titanate Sputtering Target is utilized in various applications, including thin film deposition, decorative coatings, semiconductors, displays, LEDs, and photovoltaic devices. It is also essential for functional coatings, the optical information storage industry, glass coatings for automotive and architectural purposes, and optical communication systems, among other fields.

Barium Titanate Sputtering Target Packing

Our Barium Titanate Sputtering Targets are meticulously tagged and labeled externally to ensure efficient identification and maintain stringent quality control. We take extensive precautions to prevent any damage during storage and transportation, ensuring the highest standards of product integrity upon delivery.

Get Contact

TFM offers Barium Titanate Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.