Description

Bismuth and its compounds are important materials that have a wide range of applications across various industries. As a post-transition metal, bismuth exhibits unique properties that make it valuable in fields such as electronics, medicine, and manufacturing. Bismuth-based powders are commonly used as alloying agents in metallurgy to enhance the properties of metals like lead and tin. Furthermore, bismuth compounds such as bismuth subsalicylate are used in pharmaceuticals to treat gastrointestinal issues. In electronics, bismuth-based powders contribute to the production of thermoelectric materials for energy conversion applications. Bismuth oxychloride powder is also commonly used in cosmetics to add pearlescent effects to makeup products. Additionally, bismuth powder is employed in nuclear applications for radiation shielding and in additive manufacturing processes for producing intricate components. Overall, bismuth and bismuth-based powders play a vital role in various industries, offering unique properties and versatile applications that drive technological advancements and product innovation.

Applications

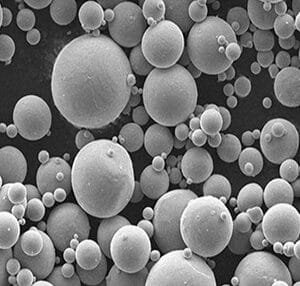

Bismuth and Bismuth-based Powders are essential materials with diverse applications across various industries. Bismuth, a post-transition metal, and its compounds exhibit unique properties that make them valuable in fields such as electronics, medicine, and manufacturing. Bismuth powder, typically produced through methods like atomization or chemical precipitation, is widely used in:

- Metallurgy:Bismuth powder is employed as an alloying agent to enhance the properties of metals such as lead, tin, and steel. Bismuth alloys are utilized in applications requiring low melting points, such as soldering and plumbing.

- Medicine:Bismuth compounds, such as bismuth subsalicylate, are commonly used in over-the-counter medications to treat gastrointestinal issues like diarrhea and indigestion. Bismuth powder may also be used in pharmaceutical formulations for its antimicrobial properties.

- Electronics:Bismuth powder is utilized in the production of thermoelectric materials for energy conversion and waste heat recovery applications. Bismuth telluride (Bi2Te3) powder, for example, is a key component in thermoelectric devices used for cooling or power generation.

- Cosmetics:Bismuth oxychloride powder is a common ingredient in cosmetics, where it imparts a pearlescent effect and enhances the texture and adhesion of makeup products like foundations, blushes, and eyeshadows.

- Nuclear Applications:Bismuth powder is used as a radiation shielding material due to its high density and effectiveness in attenuating gamma radiation. It is employed in medical imaging, nuclear reactors, and other nuclear applications.

- Manufacturing:Bismuth powder finds applications in additive manufacturing processes such as powder metallurgy and 3D printing, where it is used to produce intricate components with high precision.

Packaging

Our Bismuth Powder are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

Reviews

There are no reviews yet.