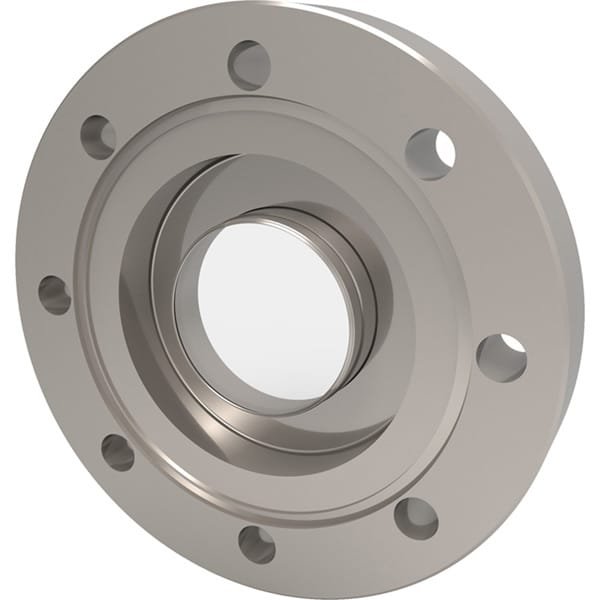

CF Flanged Sapphire Viewports: High-Performance Optical Access for UHV Systems

CF Flanged Sapphire Viewports from TFM are engineered to deliver exceptional durability and optical clarity in ultra-high vacuum (UHV) environments. Designed for compatibility with knife-edge ConFlat® (CF) flanges, these sapphire viewports are built using high-purity materials that meet the rigorous standards required for UHV performance. The robust sapphire window resists chemical attack, mechanical abrasion, and thermal cycling, making it the material of choice for challenging optical applications.

Each viewport is compatible with fully annealed copper gaskets, which minimize strain on the optical surface during sealing and bakeout processes. For systems where material deposition is a concern—such as in sputtering or etching environments—a viewport shutter is strongly recommended to protect the sapphire window and extend its service life.

Key Features of CF Flanged Sapphire Viewports:

UHV-Compatible Construction: Made from 304L stainless steel and high-purity sapphire, these viewports maintain vacuum integrity at pressures down to 10⁻¹⁰ Torr.

Excellent Mechanical and Thermal Stability: Sapphire provides high scratch resistance and can withstand significant thermal gradients, making it ideal for environments where optical access must be preserved over long operational periods.

Secure Knife-Edge Sealing: Designed for use with fully annealed copper gaskets, which reduce mechanical stress and ensure a reliable vacuum seal during thermal cycling or bakeout (up to 250°C).

Broad Spectral Transmission: Sapphire transmits light effectively from the ultraviolet (UV) through the mid-infrared (IR) range, making it ideal for spectroscopy, imaging, and diagnostics under vacuum.

Applications of CF Flanged Sapphire Viewports:

Laser and beamline diagnostics in UHV systems

Plasma monitoring in semiconductor processing tools

Optical observation in corrosive or high-temperature environments

Spectroscopy and emission analysis in research and production chambers

TFM’s CF Flanged Sapphire Viewports are designed for critical optical access in UHV environments where durability, purity, and transmission clarity are paramount. When paired with a viewport shutter, these viewports offer long-lasting performance in the harshest vacuum conditions.

Reviews

There are no reviews yet.