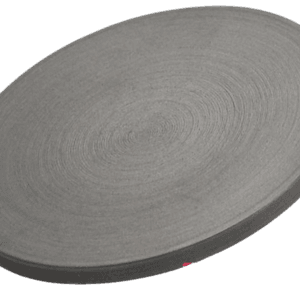

Chromium-doped Silicon Monoxide Sputtering Target Description

Chromium-doped silicon monoxide sputtering target from TFM is an oxide sputtering material containing Cr, Si, and O.

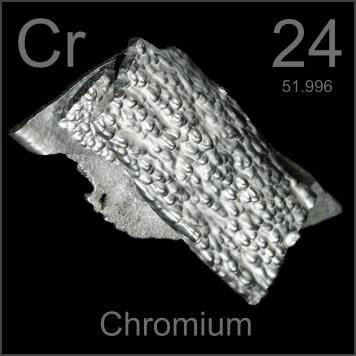

Chromium is a chemical element with the symbol “Cr,” originating from the Greek word ‘chroma,’ meaning color, due to its colorful compounds. It was first used before 1 AD and is notably associated with discoveries by the Terracotta Army. Chromium is positioned in Period 4, Group 6 of the periodic table, belonging to the d-block, with an atomic number of 24. The relative atomic mass of chromium is 51.9961(6) Dalton, indicating the uncertainty in measurement.

Related Product: Chromium Sputtering Target

![]() Silicon is a chemical element with the symbol “Si,” originating from the Latin words ‘silex’ or ‘silicis,’ meaning flint. It was first identified in 1824 by J. Berzelius, who also succeeded in isolating it. Silicon is positioned at atomic number 14 in the periodic table, located in Period 3 and Group 14, within the p-block. It has a relative atomic mass of 28.0855(3) Dalton, with the number in brackets indicating the uncertainty. Silicon is a crucial element in the electronics industry, particularly in the production of semiconductors.

Silicon is a chemical element with the symbol “Si,” originating from the Latin words ‘silex’ or ‘silicis,’ meaning flint. It was first identified in 1824 by J. Berzelius, who also succeeded in isolating it. Silicon is positioned at atomic number 14 in the periodic table, located in Period 3 and Group 14, within the p-block. It has a relative atomic mass of 28.0855(3) Dalton, with the number in brackets indicating the uncertainty. Silicon is a crucial element in the electronics industry, particularly in the production of semiconductors.

Related Products: N-type Silicon Sputtering Target, P-type Silicon Sputtering Target

Oxygen is a chemical element with the symbol “O,” originating from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first mentioned in 1771 and observed by W. Scheele, who also accomplished and announced its isolation. Oxygen has an atomic number of 8 in the periodic table, located in Period 2 and Group 16, within the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, with the number in brackets indicating the uncertainty. Oxygen is essential for life, playing a crucial role in respiration and combustion processes.

Oxygen is a chemical element with the symbol “O,” originating from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first mentioned in 1771 and observed by W. Scheele, who also accomplished and announced its isolation. Oxygen has an atomic number of 8 in the periodic table, located in Period 2 and Group 16, within the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, with the number in brackets indicating the uncertainty. Oxygen is essential for life, playing a crucial role in respiration and combustion processes.

Chromium-doped Silicon Monoxide Sputtering Target Packaging

Our chromium-doped silicon monoxide sputtering target is clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation, ensuring that the product remains in optimal condition for use.

MSDS File

MSDS File

Reviews

There are no reviews yet.