Product Overview

Key Features

- Material Type: Pure Copper (Cu)

- Color/Appearance: Metallic, Copper

- Melting Point: 1,083°C

- Density: 8.96 g/cm³

- Sputter: DC

- Bonding Types Available: Indium, Elastomer

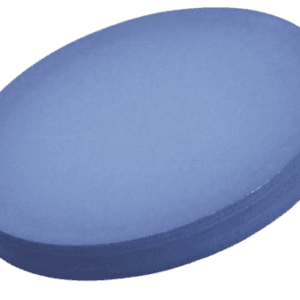

- Available Sizes: Diameters from 2.0″ to 6.0″, Thicknesses from 0.125″ to 0.250″

Advanced Specifications

Purity Levels: Our high-purity copper starts at 99.99%, ensuring superior performance in your sputtering processes.

Customization: We offer customized shapes and sizes to meet the specific needs of your applications. Contact us to discuss your requirements.

Applications

Copper sputtering targets are essential in various high-tech applications:

- Semiconductor Manufacturing: Crucial for producing semiconductors where high-purity copper ensures reliable and efficient devices.

- Thin Film Deposition: Ideal for creating conductive layers in thin-film transistors (TFTs) used in large-format, high-resolution displays.

- Photovoltaic Devices: Used in the deposition processes for solar cells, enhancing their efficiency and performance.

- Optical Storage Media: Essential for producing recording layers in CD-ROMs and other optical storage devices.

Planar and Rotary Targets

Bonding and Backing Services

Specialized bonding services for Copper Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Quality Assurance and Packaging

Our Copper Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation.

Contact Us

TFM offers Copper Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.