Dysprosium Oxide Sputtering Target Description

The Dysprosium Oxide Sputtering Target from TFM is an oxide sputtering material with the chemical formula Dy2O3.

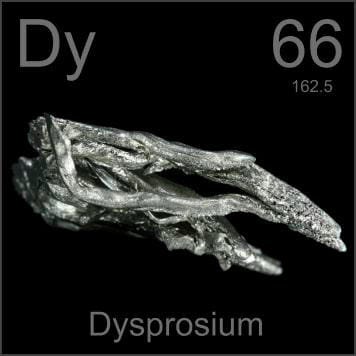

Dysprosium is a chemical element originated from the Greek ‘dysprositos’, meaning hard to get. It was first mentioned in 1886 and observed by P.E.L. de Boisbaudran. “Dy” is the canonical chemical symbol of dysprosium. Its atomic number in the periodic table of elements is 66 with location at Period 6 and Group 3, belonging to the f-block. The relative atomic mass of dysprosium is 162.500(1) Dalton, the number in the brackets indicating the uncertainty.

Dysprosium is a chemical element originated from the Greek ‘dysprositos’, meaning hard to get. It was first mentioned in 1886 and observed by P.E.L. de Boisbaudran. “Dy” is the canonical chemical symbol of dysprosium. Its atomic number in the periodic table of elements is 66 with location at Period 6 and Group 3, belonging to the f-block. The relative atomic mass of dysprosium is 162.500(1) Dalton, the number in the brackets indicating the uncertainty.

Related Product: Dysprosium Sputtering Target

Dysprosium Oxide (Dy2O3) is a sesquioxide compound of the rare earth metal dysprosium. It appears as a pastel yellowish-greenish, slightly hygroscopic powder. Dysprosium Oxide has specialized applications in ceramics, glass, phosphors, lasers, and dysprosium metal halide lamps. It reacts with acids to produce the corresponding dysprosium(III) salts, as shown in the reaction:

Dy2O3 + 6 HCl → 2 DyCl3 + 3 H2O

This reaction highlights its chemical reactivity and utility in various industrial processes.

Dysprosium Oxide Sputtering Target Specification

| Material Type | Dysprosium Oxide |

| Symbol | Dy2O3 |

| Color/Appearance | White |

| Melting Point | 2,408° C (4,366° F) |

| Type of Bond | Indium |

| Density | 7.81 g/cm3 |

Dysprosium Oxide Sputtering Target Target Bonding

Specialized bonding services for Dysprosium Oxide Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Dysprosium Oxide Sputtering Target Application

The Dysprosium Oxide Sputtering Target is utilized in a variety of applications, including thin film deposition, decorative coatings, semiconductors, displays, LEDs, and photovoltaic devices. It is also important for functional coatings, the optical information storage industry, glass coatings for automotive and architectural applications, and optical communication systems, among other fields.

Packaging

Our Dysprosium Oxide Sputtering Targets are meticulously tagged and labeled externally to ensure efficient identification and maintain strict quality control. We take extensive precautions to prevent any damage during storage and transportation, ensuring the highest standards of product integrity upon delivery.

Get Contact

TFM offers Dysprosium Oxide Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.