Gadolinium-Doped Ceria (GDC) Sputtering Target

The Gadolinium-Doped Ceria (GDC) Sputtering Target from Thin Film Materials (TFM) is a high-performance ceramic target used in thin film deposition. GDC is a solid solution of cerium oxide (CeO₂) doped with gadolinium oxide (Gd₂O₃), which enhances ionic conductivity by introducing oxygen vacancies into the lattice. Thanks to its exceptional oxygen ion transport properties, GDC is widely employed in solid oxide fuel cells (SOFCs), sensors, and energy storage devices.

Detailed Description

Our GDC sputtering targets are fabricated with high density and controlled microstructure, ensuring uniform sputtering behavior and reproducible thin film properties. Typical compositions range from 10–20 mol% Gd-doping in ceria, with purities of 99.9% (3N) to 99.99% (4N).

Chemical Formula: Ce₀.₉Gd₀.₁O₂₋ₓ (typical 10 mol% Gd)

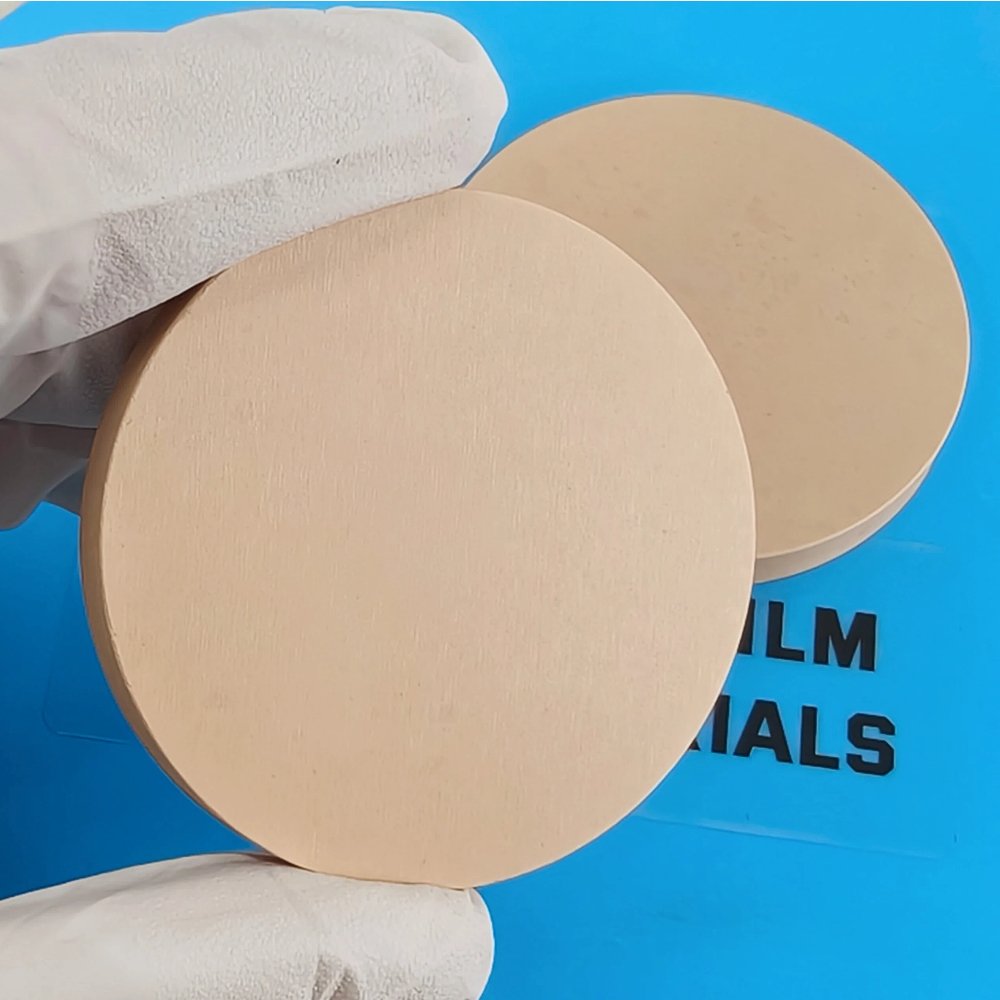

Appearance: Pale yellow to light green ceramic

Density: ~7.2 g/cm³

Crystal Structure: Cubic fluorite (stabilized by Gd³⁺ substitution)

TFM provides GDC sputtering targets in standard disc, rectangular, and step formats. Bonding services with copper or titanium backing plates are available to improve heat dissipation, mechanical stability, and target longevity. Custom sizes and doping ratios can be produced on request.

Applications

Gadolinium-Doped Ceria sputtering targets are widely used in:

Solid Oxide Fuel Cells (SOFCs): electrolyte and buffer layers to enhance ionic conductivity

Gas sensors: oxygen and hydrogen sensing devices

Catalysis: films for catalytic converters and oxygen storage systems

Photovoltaics and optoelectronics: buffer layers in solar cells and functional coatings

R&D: advanced studies of oxygen ion conductors and ceramic thin films

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | High purity ensures low defect levels in films |

| Doping Level | 10–20 mol% Gd | Adjusts ionic conductivity and stability |

| Diameter | 25 – 150 mm (custom up to 300 mm) | Fits a wide range of sputtering systems |

| Thickness | 3 – 6 mm | Controls sputtering efficiency and film uniformity |

| Bonding Options | Indium / Elastomer | Improves thermal transfer and adhesion |

| Backing Plate | Copper / Titanium | Ensures mechanical stability during sputtering |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| GDC (CeO₂:Gd₂O₃) | High ionic conductivity at low temp | SOFC electrolytes, sensors |

| YSZ (Yttria-Stabilized Zirconia) | Stable at higher temperatures | SOFC electrolytes |

| SDC (Samarium-Doped Ceria) | Alternative oxygen ion conductor | Fuel cells, catalysis |

FAQ

| Question | Answer |

|---|---|

| Can the Gd-doping ratio be customized? | Yes, TFM offers 10–20 mol% Gd doping or as specified by customer needs. |

| Do you offer bonded targets? | Yes, bonding with indium or elastomer to Cu/Ti backing plates is available. |

| How are GDC targets packaged? | Each target is vacuum-sealed, cushioned with foam, and shipped in export-safe cartons or crates. |

| Which industries use GDC most? | Energy (SOFC), catalysis, sensor technology, and R&D institutions. |

Packaging

All Gadolinium-Doped Ceria sputtering targets are vacuum-sealed, protected with foam, and packed in export-safe cartons or wooden crates. This ensures safe transport, long-term stability, and preserved quality.

Conclusion

The Gadolinium-Doped Ceria (GDC) Sputtering Target from TFM provides high ionic conductivity, excellent stability, and reliable thin film performance. With customizable dimensions, doping levels, and bonding services, our GDC targets meet the exacting needs of energy, electronics, and research applications.

For detailed specifications, pricing, and custom solutions, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.