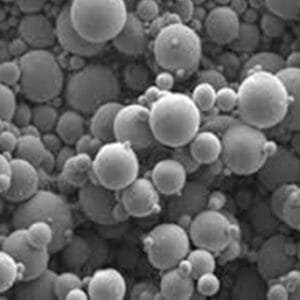

Inconel 718 Powder Description

Inconel 718 (Alloy 718, UNS N07718) is a high-strength, corrosion-resistant nickel-chromium material used at -423° to 1300°F. The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to post-weld cracking, are outstanding.

The ease and economy of the fabrication of INCONEL 718, combined with good tensile, fatigue, creep, and rupture strength, have resulted in its use in a wide range of applications. Examples of these are components for liquid fueled rockets, rings, casings and various formed sheet metal parts for aircraft and land-based gas turbine engines, and cryogenic tankage.

Furthermore, Inconel 718 Powder plays an important role in additive manufacturing (3D printing).

Inconel 718 Powder Specifications

| Product Name | Inconel 718 powder |

| Alloy Grade | Inconel 718 |

| Related Grades | Nickel Alloy In718, CL100NB, B50TF202, B50A917 |

| Composition | Cr 17-21 Mo 2.8-3.3 Mn 0.35 max |

| Size Grades | -105+45micron -53+15micron |

| ASTM | B537, B670 |

| AMS Specification | 5832, 5596 |

Inconel 718 Powder Applications

Inconel 718 Powder plays an important role in additive manufacturing (3D printing). IN718 was firstly designed and introduce to overcome the poor weldability of superalloys in the 1960s. But now IN718 is being used intensively in gas turbines and aero engines for discs and frames. Due to IN718’s excellent weldability and similarity of the AM and welding processes, IN718 has been widely applied in metallic AM fields to understand the fundamentals of AM processes.

Reference

Dunyong Deng: Additively Manufactured Inconel 718: Microstructures and Mechanical Properties. https://www.diva-portal.org/smash/get/diva2:1177201/FULLTEXT02.pdf

Reviews

There are no reviews yet.