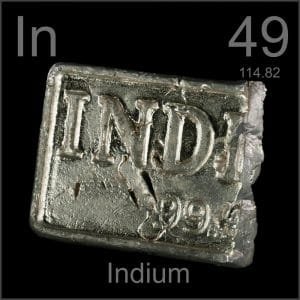

Indium Sputtering Target Description

The indium sputtering target is a silvery, lustrous gray target made from high-purity indium metal. Indium, symbolized as “In,” derives its name from the Latin word ‘indicium,’ meaning violet or indigo. First mentioned in 1863 by F. Reich and T. Richter, who later isolated it, indium has an atomic number of 49, located in Period 5, Group 13 of the periodic table, within the p-block. Its relative atomic mass is 114.818(3) Dalton, with the number in brackets indicating uncertainty.

Indium compounds are evaporated under vacuum to form thin films used in electronics and photovoltaic cells. Pure indium is also used as a film layer in semiconductors.

Indium Sputtering Target Specification

| Material Type | Indium |

| Symbol | In |

| Color/Appearance | Silvery Lustrous Gray, Metallic |

| Melting Point | 157 °C |

| Type of Bond | Elastomer |

| Density | 7.3 g/cc |

| Thermal Conductivity | 82 W/m.K |

| Coefficient of Thermal Expansion | 32.1 x 10-6/K |

| Comments | Wets W and Cu. Use Mo liner. Low Melting Point materials not ideal for sputtering. |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Indium Sputtering Target Applications

Indium Sputtering Target Target Bonding

Specialized bonding services for Indium Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Packaging

Our Indium Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation.

Get Contact

TFM offers Indium Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.