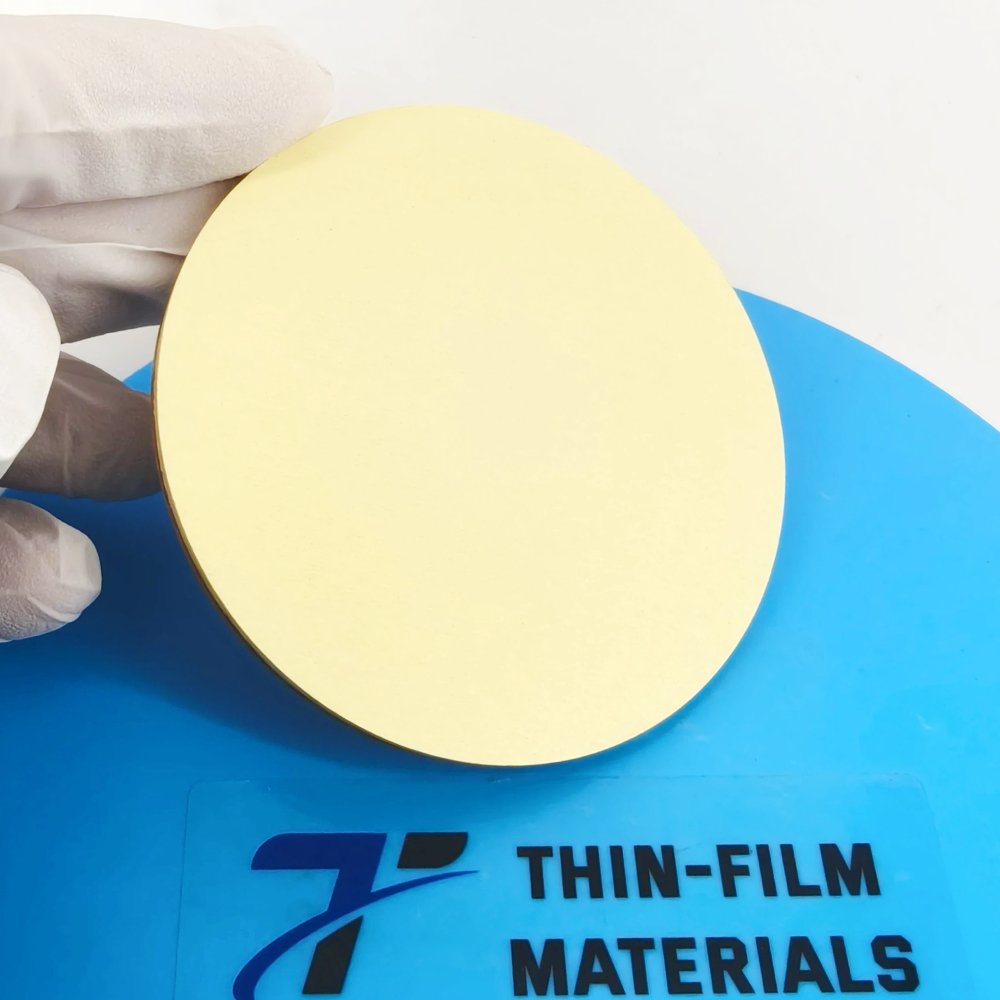

Indium Zinc Oxide Sputtering Target

Introduction

The Indium Zinc Oxide (IZO) Sputtering Target is a key material in the thin film industry, known for its excellent electrical conductivity and high optical transparency. As a mixed oxide composed of indium oxide (In₂O₃) and zinc oxide (ZnO), it serves as an advanced alternative to ITO (Indium Tin Oxide) in transparent conductive film applications, offering improved stability, flexibility, and lower deposition temperatures.

Detailed Description

Indium Zinc Oxide (IZO) targets typically contain 5–20 wt% ZnO and 80–95 wt% In₂O₃, optimized to balance conductivity and transparency. The addition of ZnO enhances the film’s chemical stability and flexibility, making it suitable for next-generation electronics and display technologies.

IZO sputtering targets are produced via hot pressing or vacuum sintering, resulting in a dense and homogeneous ceramic structure. This ensures uniform sputtering rates, reduced particle generation, and superior adhesion on glass or polymer substrates.

Key Features:

High transparency (>85%) in the visible light range.

Low resistivity and stable electrical properties.

Excellent adhesion and film uniformity.

Low processing temperature, compatible with plastic and flexible substrates.

Custom ZnO ratios available for specific device needs.

Applications

Indium Zinc Oxide sputtering targets are widely used in:

Flat-panel displays (FPDs) – including OLED and LCD electrodes.

Touch screens and flexible electronics.

Photovoltaic devices – transparent conductive layers in solar cells.

Optoelectronic devices – such as LEDs and sensors.

Smart windows and low-emissivity glass coatings.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Chemical Formula | (In₂O₃)₁₋ₓ(ZnO)ₓ | Defines optical & electrical balance |

| Purity | 99.9% – 99.99% | Ensures clean and defect-free films |

| Composition Ratio | In₂O₃:ZnO = 90:10 (wt%) | Tunable for performance optimization |

| Density | ≥ 7.1 g/cm³ | Improves sputtering efficiency |

| Diameter | 25 – 300 mm (custom) | Fits all sputtering systems |

| Thickness | 3 – 10 mm | Determines sputtering lifetime |

| Backing Plate | Copper / Titanium | Improves heat transfer and mechanical stability |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Indium Zinc Oxide (IZO) | High transparency & flexibility | Touch panels & displays |

| Indium Tin Oxide (ITO) | High conductivity, rigid | Glass-based coatings |

| Aluminum Zinc Oxide (AZO) | Cost-effective, transparent | Solar cells |

| Fluorine-doped Tin Oxide (FTO) | Durable, conductive at high temps | Architectural glass |

FAQ

| Question | Answer |

|---|---|

| Can the ZnO ratio be customized? | Yes, ZnO content can be tailored (typically 5–20 wt%) to control resistivity and transparency. |

| What bonding options are available? | Commonly copper or titanium backing plates. |

| Is IZO compatible with flexible substrates? | Yes, it can be sputtered at lower temperatures, ideal for polymer substrates. |

| How is it packaged? | Vacuum-sealed with desiccant, foam protection, and export-safe wooden crates. |

| What industries use IZO most? | Displays, photovoltaics, and optoelectronics. |

Indium Zinc Oxide Sputtering Target Bonding Service

Specialized bonding services for Indium Zinc Oxide Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Packaging

Each Indium Zinc Oxide Sputtering Target is individually vacuum-packed in a clean environment with protective foam and clear labeling. Export packaging includes moisture-proof wrapping and reinforced cartons or crates to ensure safe transport.

Conclusion

The Indium Zinc Oxide Sputtering Target offers a superior combination of transparency, conductivity, and flexibility, making it a preferred choice for modern optoelectronic devices and display technologies. Its stable deposition behavior and customizable composition enable precise thin film engineering across multiple industries.

For detailed specifications and quotations, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.