Lanthanum Niobium Oxide Sputter Target Description

The Lanthanum Niobium Oxide Sputtering Target from TFM is an oxide sputtering material composed of lanthanum (La), niobium (Nb), and oxygen (O).

Lanthanum is a soft, malleable, silvery-white metal and one of the most reactive rare earth elements. It is used in the production of special optical glasses and to improve the malleability of steel. Additionally, lanthanum is valuable in wastewater treatment and oil refining processes. Scientists have nicknamed lanthanum “super calcium” due to its application in photoconversion films, which enhance the efficiency of solar cells by converting ultraviolet light into visible light.

Lanthanum is a soft, malleable, silvery-white metal and one of the most reactive rare earth elements. It is used in the production of special optical glasses and to improve the malleability of steel. Additionally, lanthanum is valuable in wastewater treatment and oil refining processes. Scientists have nicknamed lanthanum “super calcium” due to its application in photoconversion films, which enhance the efficiency of solar cells by converting ultraviolet light into visible light.

Related Product: Lanthanum Sputtering Target

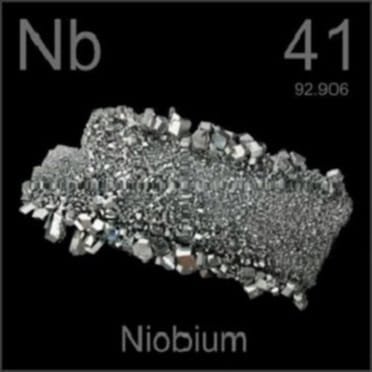

Niobium is a silver-colored metal that is generally found in conjunction with tantalum, the two elements being separated by fractional crystallization of their respective fluoro-complexes. It has an abundance of 20 ppm in the earth’s crust. As a pure metal, it is very reactive and forms an extremely stable oxide when exposed to air which enhances its corrosion resistance. Niobium will react with a variety of non-metals at elevated temperatures.

Niobium is a silver-colored metal that is generally found in conjunction with tantalum, the two elements being separated by fractional crystallization of their respective fluoro-complexes. It has an abundance of 20 ppm in the earth’s crust. As a pure metal, it is very reactive and forms an extremely stable oxide when exposed to air which enhances its corrosion resistance. Niobium will react with a variety of non-metals at elevated temperatures.

Related Product: Niobium Sputtering Target

Oxygen is a chemical element that originated from the Greek ‘oxy’ and ‘genes’ meaning acid-forming. It was first mentioned in 1771 and observed by W. Scheele. The isolation was later accomplished and announced by W. Scheele. “O” is the canonical chemical symbol of oxygen. Its atomic number in the periodic table of elements is 8 with a location at Period 2 and Group 16, belonging to the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, the number in the brackets indicating the uncertainty.

Oxygen is a chemical element that originated from the Greek ‘oxy’ and ‘genes’ meaning acid-forming. It was first mentioned in 1771 and observed by W. Scheele. The isolation was later accomplished and announced by W. Scheele. “O” is the canonical chemical symbol of oxygen. Its atomic number in the periodic table of elements is 8 with a location at Period 2 and Group 16, belonging to the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, the number in the brackets indicating the uncertainty.

Lanthanum Niobium Oxide Sputter Target Handling Notes

- Indium Bonding: Indium bonding is recommended for the lanthanum niobium oxide sputtering target due to its brittleness and low thermal conductivity, which make it less suitable for traditional sputtering methods.

- Thermal Conductivity: This material has low thermal conductivity and is susceptible to thermal shock. Proper handling and bonding techniques are essential to prevent damage during the sputtering process.

MSDS File

MSDS File

Reviews

There are no reviews yet.