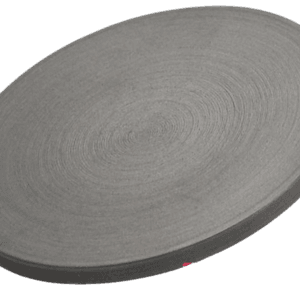

Lanthanum Titanate Sputtering Target Description

The Lanthanum Titanate Sputtering Target from TFM is an oxide sputtering material composed of lanthanum (La), titanium (Ti), and oxygen (O).

Lanthanum is a soft, malleable, silvery-white metal and one of the most reactive rare earth elements. It is used in the production of special optical glasses and to improve the malleability of steel. Additionally, lanthanum is valuable in wastewater treatment and oil refining processes. Scientists have nicknamed lanthanum “super calcium” due to its use in photoconversion films, which enhance the efficiency of solar cells by converting ultraviolet light into visible light.

Lanthanum is a soft, malleable, silvery-white metal and one of the most reactive rare earth elements. It is used in the production of special optical glasses and to improve the malleability of steel. Additionally, lanthanum is valuable in wastewater treatment and oil refining processes. Scientists have nicknamed lanthanum “super calcium” due to its use in photoconversion films, which enhance the efficiency of solar cells by converting ultraviolet light into visible light.

Related Product: Lanthanum Sputtering Target

Titanium is a chemical element named after the Titans, the sons of the Earth goddess in Greek mythology. It was first mentioned in 1791 and observed by W. Gregor, with its isolation later accomplished and announced by J. Berzelius. The chemical symbol for titanium is “Ti,” and its atomic number is 22. Titanium is located in Period 4, Group 4 of the periodic table, within the d-block. Its relative atomic mass is 47.867(1) Dalton, with the number in brackets indicating the measurement uncertainty. Titanium is known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it widely used in aerospace, medical implants, and various industrial applications.

Titanium is a chemical element named after the Titans, the sons of the Earth goddess in Greek mythology. It was first mentioned in 1791 and observed by W. Gregor, with its isolation later accomplished and announced by J. Berzelius. The chemical symbol for titanium is “Ti,” and its atomic number is 22. Titanium is located in Period 4, Group 4 of the periodic table, within the d-block. Its relative atomic mass is 47.867(1) Dalton, with the number in brackets indicating the measurement uncertainty. Titanium is known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it widely used in aerospace, medical implants, and various industrial applications.

Related Product: Titanium Sputtering Target

Oxygen is a chemical element whose name comes from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first mentioned and observed by W. Scheele in 1771, who also later accomplished and announced its isolation. The chemical symbol for oxygen is “O,” and its atomic number is 8. Oxygen is located in Period 2, Group 16 of the periodic table, within the p-block. Its relative atomic mass is 15.9994(3) Dalton, with the number in brackets indicating the measurement uncertainty. Oxygen is essential for respiration in most life forms and plays a critical role in combustion, oxidation, and various chemical processes.

Oxygen is a chemical element whose name comes from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first mentioned and observed by W. Scheele in 1771, who also later accomplished and announced its isolation. The chemical symbol for oxygen is “O,” and its atomic number is 8. Oxygen is located in Period 2, Group 16 of the periodic table, within the p-block. Its relative atomic mass is 15.9994(3) Dalton, with the number in brackets indicating the measurement uncertainty. Oxygen is essential for respiration in most life forms and plays a critical role in combustion, oxidation, and various chemical processes.

Available Sizes of Lanthanum Titanate Sputtering Target

| Material | Size |

| Lanthanum Titanate, LaTiO3 | 2.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 2.00″ Dia. x 0.250″ Thick |

| Lanthanum Titanate, LaTiO3 | 3.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 3.00″ Dia. x 0.250″ Thick |

| Lanthanum Titanate, LaTiO3 | 4.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 4.00″ Dia. x 0.250″ Thick |

| Lanthanum Titanate, LaTiO3 | 5.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 5.00″ Dia. x 0.250″ Thick |

| Lanthanum Titanate, LaTiO3 | 6.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 6.00″ Dia. x 0.250″ Thick |

| Lanthanum Titanate, LaTiO3 | 7.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 7.00″ Dia. x 0.250″ Thick |

| Lanthanum Titanate, LaTiO3 | 8.00″ Dia. x 0.125″ Thick |

| Lanthanum Titanate, LaTiO3 | 8.00″ Dia. x 0.250″ Thick |

Lanthanum Titanate Sputtering Target Target Bonding

Indium Bonding is available for Lanthanum Titanate Sputtering Targets. TFM offers machining of standard backing plates and collaborates with the Taiwan Bonding Company to provide high-quality bonding services. This ensures optimal performance and longevity of the sputtering targets during use.

Lanthanum Titanate Sputtering Target Packaging

Our Lanthanum Titanate Sputter Targets are meticulously handled to prevent any damage during storage and transportation, ensuring that the products maintain their original high quality. We prioritize careful packaging and handling procedures to preserve the integrity and performance of our sputtering targets.

Get Contact

TFM offers Lanthanum Titanate Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.