Leco® Platinum Crucibles & Molds Description

Platinum is a remarkable transition metal, recognized for its density, malleability, and ductility. Its lustrous, silver-white appearance and high resistance to chemical reactions make it a highly sought-after material. Unlike many other metals, platinum remains impervious to oxygen and water, and it dissolves only in a mixture of aqua regia or when exposed to fused alkalis.

Leco® Platinum Crucibles & Molds Specification

| Size | Customized |

| Material | PtAu5 (95% Pt and 5% Au) |

| Purity | Pt ≥ 99.95% |

Below is our regular product list. Custom-made items are also available upon request. All weights are in grams and all dimensions are in millimeters.

Leco® Platinum Crucibles

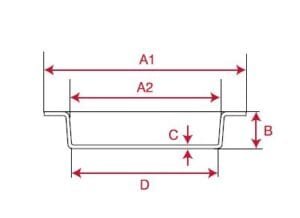

Code | B | A2 | D | A1 | Weight |

PT9801 | 35 | 37 | 20 | 44 | 45 |

PT9802 | 38 | 35 | 21 | 44 | 45 |

Leco® Platinum Molds

Code | D2 | A2 | A1 | B | C | Weight |

PT9803 | 35 | 36 | 44 | 7.2 | 0.8 | 35 |

PT9804 | 35 | 38.5 | 44 | 7.2 | 0.8 | 45 |

PT9805 | 39 | 41 | 47 | 4.2 | 0.8 | 40 |

PT9806 | 39 | 41 | 52 | 5 | 0.8 | 40 |

Leco® Platinum Crucibles & Molds Packaging

Our Leco® Platinum Crucibles & Molds are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Reviews

There are no reviews yet.