Li₀.₃₈La₀.₅₆TiO₃ Sputtering Target – All You Need to KnowLi₀.₃₈La₀.₅₆TiO₃ Sputtering Target

Introduction

Li₀.₃₈La₀.₅₆TiO₃ (Lithium Lanthanum Titanate, often abbreviated as LLTO) Sputtering Target is a perovskite-type oxide material known for its high lithium-ion conductivity, chemical stability, and compatibility with advanced thin film applications. This compound plays a key role in the research and production of solid-state batteries, thin film electrolytes, and energy storage devices, where ionic transport efficiency and structural integrity are crucial.

Detailed Description

Li₀.₃₈La₀.₅₆TiO₃ is typically synthesized through solid-state reaction or sol–gel processing, resulting in a dense, homogeneous ceramic target. The material’s structure—based on a perovskite framework (ABO₃)—provides high Li⁺ ion mobility due to vacancies in the lattice, making it one of the most promising solid electrolytes for next-generation energy systems.

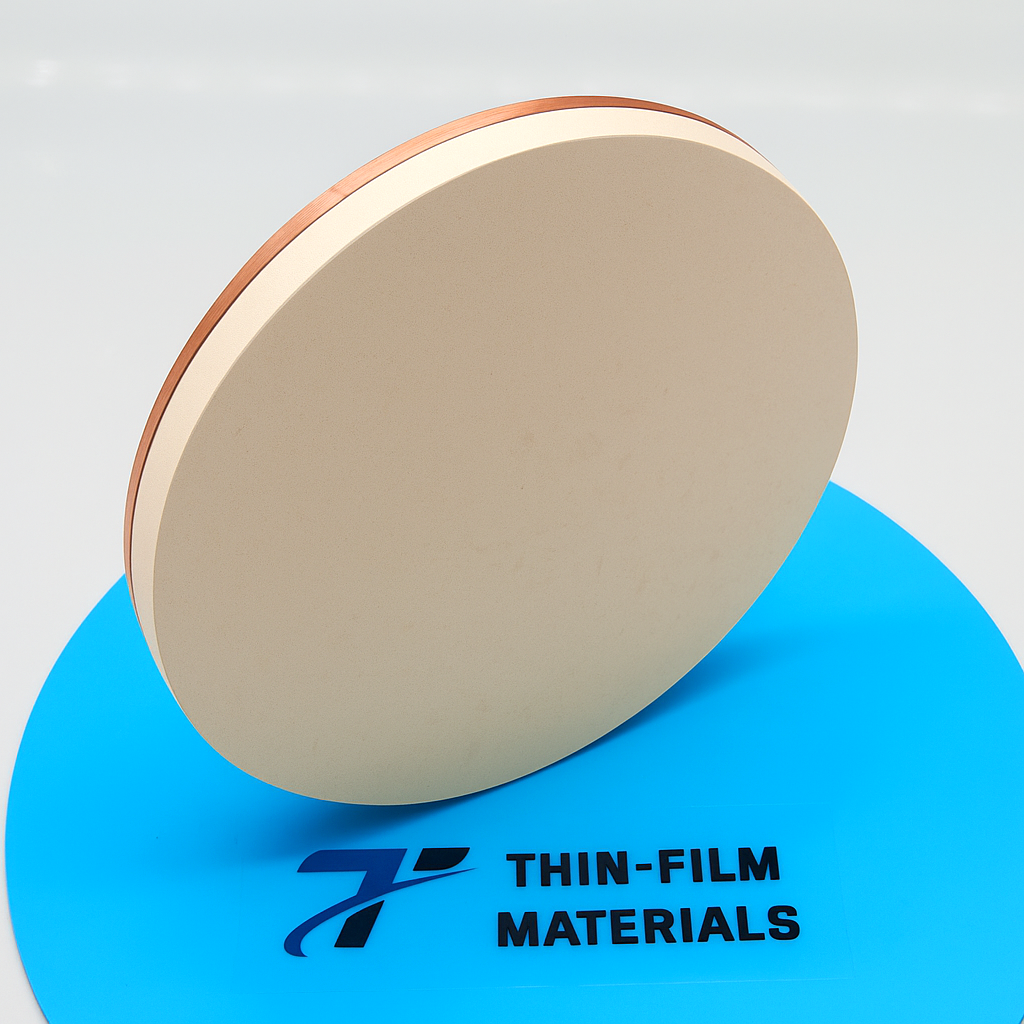

When fabricated as a sputtering target, the LLTO material can be bonded to a copper backing plate to enhance heat dissipation and ensure mechanical stability during magnetron sputtering. Typical targets are sintered to high density (>95%) to achieve uniform sputtering rates and consistent thin film composition.

Applications

Li₀.₃₈La₀.₅₆TiO₃ Sputtering Targets are widely used in the following fields:

Solid-State Batteries: as thin-film solid electrolytes with high ionic conductivity.

Microelectronic Devices: for interface layers and dielectric films.

Energy Storage Systems: for advanced lithium-ion and lithium-metal cell development.

Optoelectronic Thin Films: as part of multi-layer oxide stacks requiring ionic mobility control.

Research & Development: for exploring lithium-ion conducting oxide materials and solid-state interfaces.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Composition | Li₀.₃₈La₀.₅₆TiO₃ | High Li-ion conductivity |

| Purity | 99.9% (3N) | Ensures stable sputtering and film quality |

| Density | ≥ 95% theoretical | Promotes uniform sputtering |

| Diameter | 25 – 100 mm (customizable) | Compatible with standard sputtering systems |

| Thickness | 3 – 6 mm | Controls sputtering duration and stability |

| Bonding | Copper backing plate (In-bonded or elastomer) | Enhances thermal conductivity |

| Crystal Structure | Perovskite | Enables ionic mobility |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Li₀.₃₈La₀.₅₆TiO₃ | High ionic conductivity and thermal stability | Solid-state electrolytes |

| Li₇La₃Zr₂O₁₂ (LLZO) | Wider electrochemical window | Li-metal battery electrolyte |

| Li₃PO₄ | Excellent chemical stability | Thin-film lithium batteries |

| Al₂O₃ | High dielectric strength | Protective or insulating layers |

FAQ

| Question | Answer |

|---|---|

| Can the target be customized? | Yes, dimensions, purity, and bonding type can be tailored to your sputtering system. |

| What backing plate options are available? | Typically copper or titanium, bonded with indium or elastomer. |

| How is the target packaged? | Vacuum-sealed with protective foam in export-safe cartons or wooden crates. |

| What sputtering methods are compatible? | Suitable for RF and DC magnetron sputtering systems. |

| What industries use this target most? | Battery research, microelectronics, and materials science. |

Packaging

Each Li₀.₃₈La₀.₅₆TiO₃ Sputtering Target is securely labeled and vacuum-sealed to prevent contamination and moisture absorption. The packaging meets international export standards, ensuring safe delivery to research labs and production facilities worldwide.

Conclusion

Li₀.₃₈La₀.₅₆TiO₃ Sputtering Target provides a reliable and efficient material solution for thin-film solid electrolytes and advanced energy applications. With excellent ionic conductivity, high purity, and stable performance, it has become a key component in the development of all-solid-state lithium batteries.

For detailed specifications and quotations, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.