Low and Wide Base Platinum Crucible Description

Platinum crucibles with a low and wide base exhibit characteristics similar to their parent metal. Known for its minimal reactivity, platinum offers exceptional resistance to corrosion, even under extreme temperatures. This makes platinum the material of choice for high-quality laboratory equipment.

Our low and wide base platinum crucibles are crafted from 99.95% pure platinum and platinum alloys. They feature robust, thicker bases and lighter walls, ensuring they can withstand rigorous use while maintaining their structural integrity.

Low and Wide Base Platinum Crucible Specification

Size: 5ml – 125ml or customized

Material: Platinum (Pt), PtAu5 (95% Pt and 5% Au), PtIr5 (95% Pt and 5% Ir), PtRh5 (95% Pt and 5% Rh)

Purity: Pt ≥ 99.95%, Ir ≥ 99.99%, Rh ≥ 99.99%, Au ≥ 99.99%

Below is our product list, we can also provide customized low and wide base crucibles.

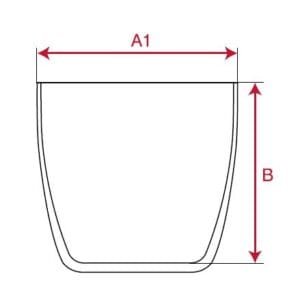

All weights are in grams and all dimensions are in millimeters.

Code | Description | Capacity(ml) | B | A1 | Standard Weight | Reinforced base and rim Weight range | Lid Weight |

PT9501 | Low and wide crucible, 5ml | 5 | 20 | 26 | 4 | 6 | 3 |

PT9502 | Low and wide crucible, 8ml | 8 | 21 | 25 | 6 | 8 | 3 |

PT9503 | Low and wide crucible, 10ml | 10 | 23 | 27 | 7 | 9 | 3 |

PT9504 | Low and wide crucible, 10ml | 10 | 24 | 29 | 8 | 13 | 3 |

PT9505 | Low and wide crucible, 12ml | 12 | 25 | 30 | 10 | 13 | 3 |

PT9506 | Low and wide crucible, 15ml | 15 | 27 | 30 | 11 | 14 | 3 |

PT9507 | Low and wide crucible, 15ml | 15 | 27 | 32 | 13 | 19 | 3 |

PT9508 | Low and wide crucible, 20ml | 20 | 28 | 33 | 15 | 18 | 4 |

PT9509 | Low and wide crucible, 20ml | 20 | 31 | 37 | 18 | 26 | 4 |

PT9510 | Low and wide crucible, 25ml | 25 | 30 | 36 | 19 | 23 | 4 |

PT9511 | Low and wide crucible, 25ml | 25 | 34 | 41 | 25 | 35 | 4 |

PT9512 | Low and wide crucible, 30ml | 30 | 32 | 40 | 22 | 27 | 6 |

PT9513 | Low and wide crucible, 30ml | 30 | 34 | 38 | 25 | 31 | 6 |

PT9514 | Low and wide crucible, 35ml | 35 | 33 | 42 | 25 | 32 | 6 |

PT9515 | Low and wide crucible, 35ml | 35 | 36 | 44 | 26 | 38 | 6 |

PT9516 | Low and wide crucible, 40ml | 40 | 34 | 43 | 30 | 36 | 7 |

PT9517 | Low and wide crucible, 40ml | 40 | 40 | 45 | 30 | 41 | 7 |

PT9518 | Low and wide crucible, 50ml | 50 | 42 | 50 | 36 | 51 | 8 |

PT9519 | Low and wide crucible, 50ml | 50 | 41 | 50 | 39 | 58 | 8 |

PT9520 | Low and wide crucible, 60ml | 60 | 39 | 48 | 46 | 54 | 9 |

PT9521 | Low and wide crucible, 70ml | 70 | 41 | 52 | 50 | 63 | 12 |

PT9522 | Low and wide crucible, 70ml | 70 | 45 | 55 | 53 | 75 | 12 |

PT9523 | Low and wide crucible, 80ml | 80 | 47 | 52 | 51 | 72 | 14 |

PT9524 | Low and wide crucible, 90ml | 90 | 48 | 57 | 52 | 81 | 15 |

PT9525 | Low and wide crucible, 100ml | 100 | 48 | 62 | 70 | 91 | 17 |

PT9526 | Low and wide crucible, 120ml | 120 | 57 | 57 | 84 | 98 | 22 |

PT9527 | Low and wide crucible, 125ml | 125 | 59 | 59 | 97 | 114 | 25 |

Low and Wide Base Platinum Crucible Packaging

Our Low and Wide Base Platinum Crucibles are meticulously tagged and labeled on the exterior to facilitate easy identification and ensure rigorous quality control. We prioritize safeguarding these crucibles from potential damage during both storage and transportation.

For additional support, please refer to our Platinum Maintenance Guide to help you keep your crucibles in optimal condition.

Reviews

There are no reviews yet.