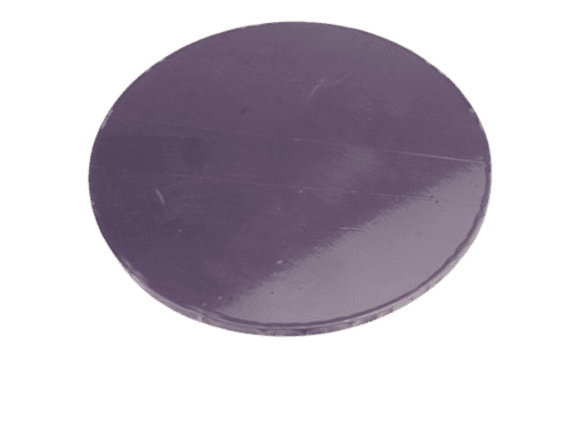

Neodymium Boride Sputtering Target Description

A Neodymium Boride Sputtering Target is a type of ceramic material composed of neodymium and boron, used in sputtering processes. This target is typically employed in thin film deposition and various specialized applications due to the unique properties of the neodymium-boron combination.

Neodymium is a chemical element with the symbol “Nd” and an atomic number of 60. The name “neodymium” originates from the Greek words ‘neos didymos,’ meaning new twin. It was first mentioned in 1885 and observed by Carl Auer von Welsbach. Neodymium is located in Period 6 and Group 3 of the periodic table, belonging to the f-block elements. Its relative atomic mass is approximately 144.242 Daltons, with the number in parentheses indicating a margin of uncertainty.

Neodymium is a chemical element with the symbol “Nd” and an atomic number of 60. The name “neodymium” originates from the Greek words ‘neos didymos,’ meaning new twin. It was first mentioned in 1885 and observed by Carl Auer von Welsbach. Neodymium is located in Period 6 and Group 3 of the periodic table, belonging to the f-block elements. Its relative atomic mass is approximately 144.242 Daltons, with the number in parentheses indicating a margin of uncertainty.

Related Product: Neodymium Sputtering Target

Boron is a chemical element with the symbol “B” and an atomic number of 5. The name “boron” originates from the Arabic word ‘buraq,’ which referred to borax. It was first mentioned in 1808 and observed by Louis-Joseph Gay-Lussac and Louis Jacques Thénard. The isolation of boron was later accomplished and announced by Humphry Davy. Boron is located in Period 2 and Group 13 of the periodic table, classified within the p-block elements. Its relative atomic mass is approximately 10.811 Daltons, with the number in parentheses indicating a margin of uncertainty.

Boron is a chemical element with the symbol “B” and an atomic number of 5. The name “boron” originates from the Arabic word ‘buraq,’ which referred to borax. It was first mentioned in 1808 and observed by Louis-Joseph Gay-Lussac and Louis Jacques Thénard. The isolation of boron was later accomplished and announced by Humphry Davy. Boron is located in Period 2 and Group 13 of the periodic table, classified within the p-block elements. Its relative atomic mass is approximately 10.811 Daltons, with the number in parentheses indicating a margin of uncertainty.

Packaging

Our Neodymium Boride Sputtering Targets are carefully packaged in plastic vacuum bags to prevent damage during storage and transportation and to preserve the quality of our products in their original condition. Additionally, the Certificate of Analysis (COA) of the raw material is included with the product packaging to ensure quality assurance and traceability.

Reviews

There are no reviews yet.