Neodymium Sputtering Target Description

Neodymium Sputtering Target Specification

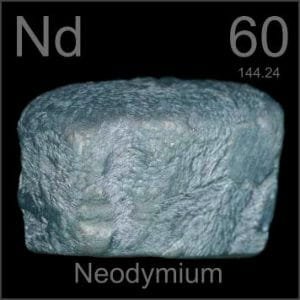

| Material Type | Neodymium |

| Symbol | Nd |

| Color/Appearance | Silvery, Metallic |

| Melting Point | 1244°C |

| Density | ~7.3 g/cm3 |

| Thermal Conductivity | 0.0781 W/cm/K @ 25 °C |

| Electrical Resistivity | 185.0 microhm-cm @ 25°C |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Neodymium Sputtering Target Application

Neodymium Sputtering Target Packaging

Our Neodymium Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation.

Get Contact

TFM offers Neodymium Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.