Nickel Metal powder

| Grade | Product Name | Chemical Composition (wt%) | Particle Size | Melting Point (℃) | Apparent Density (g/cm3) | Flow Rate | Properties |

|---|---|---|---|---|---|---|---|

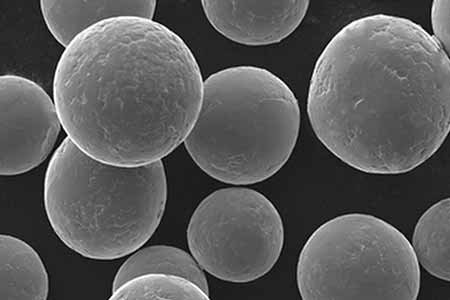

| Ni-1 | Electrolytic Nickel powder | Ni+ Co: ≥ 99.5% Other: ≤ 0.5% | -200 mesh -300 mesh customized sizes avaliable | 1455℃ | 1.20 – 1.40 | – | Gray-black dendritic powder |

| Ni-2 | Reduced Nickel powder | Ni: ≥ 99.5% C: ≤ 0.08% Other: ≤ 0.3% | ≤ 5 um customized sizes avaliable | 1455℃ | 1.0 – 2.0 | – | Gray-black dendritic powder |

| Ni-3 | Atomized Nickel powder | Ni+ Co: ≥ 99.8% C: ≤ 0.03% Fe: ≤ 0.04% Si: ≤ 0.03% Other: ≤ 0.5% | -200 mesh customized sizes avaliable | 1455℃ | 1.8 – 4.8 | ≤ 30 S/50g | Gray quasi-spherical powder |

Nickel Alloy Powder (Thermal Sparaying and Welding Powder)

These powders, including Ni-B-Si, Ni-Cr-B-Si, Ni-Cr-B-Si-P, Ni-Cr-B-Si-Cu-Mo, Ni-Cr-B-Si-W, Ni-Cr, and Ni-Cu alloys, offer excellent corrosion and oxidation resistance. Below 500°C, they provide superior low-stress abrasion and adhesive wear resistance.

They can be used in various processes such as oxyacetylene spraying, HVOF/HFAF spraying, plasma transferred arc (PTA) overlaying, plasma spraying, laser overlaying, induction melting overlaying, centrifugal casting, 3D printing, and powder metallurgy.

Key applications include valve gates, ball valve surfaces, valve seats, pistons, plastic extruder screws, glass molds, steel mill rolls, wire drawing rolls, oil pumping shafts, fan blades, screw conveyors, and tungsten carbide tools.

Nickel Base Self-Melting Alloy Powder

| Grade | Hardness(HRC) | Chemical Composition | Other | Particle Size (mesh) | Application | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | B | |||||||

| Ni15AA | 15 | 0.03 | 0.46 | 2.3 | 0.46 | Bal | 0.09 | 0.9 | Cu:20.0 | 180/500 | Bonding layer for WC coating | |||||

| Ni20M | 20 | 0.03 | 4.5 | 2 | Bal | 0.7 | 180/500 | Glass molds or other molds | ||||||||

| Ni22AA | 22 | 0.2 | 0.1 | 2.85 | 0.5 | Bal | 0.5 | 1.45 | 180/500、100/270 | Glass molds or other molds | ||||||

| Ni22M1 | 26 | 0.03 | 0.5 | 3 | 0.5 | Bal | 0.5 | 1 | 180/500 | Glass molds or other molds | ||||||

| Ni25 | 25 | 0.2 | 3.5 | 8 | Bal | 1.5 | 180/500、150/300 | Glass molds or other molds | ||||||||

| Ni28M | 28 | 0.05 | 0.1 | 2.8 | Bal | 1 | 180/500 | Glass molds or other molds | ||||||||

| Ni30AA | 30 | 0.15Max | 2.5 | 2.6 | 1 | Bal | 0.3 | 1.4 | 180/500、150/300 | Rails, gear teeth | ||||||

| Ni31M | 31 | 0.05Max | 4 | 2.4 | 3 | Bal | 0.9 | 180/500 | Glass molds or other molds | |||||||

| Ni31M1 | 32 | 0.05Max | 3.5 | 3.2 | 3.0Max | 0.1 | Bal | 0.3 | 0.9 | 180/500 | Glass molds or other molds | |||||

| Ni35AA | 35 | 0.2 | 4 | 3.2 | 1.4 | Bal | 0.1 | 1.6 | 150/300 | Glass molds or value seats | ||||||

| Ni35 | 35 | 0.3 | 10.5 | 3.5 | 10 | Bal | 2 | 150/300 | Glass molds or other molds | |||||||

| Ni36M | 36 | 0.05Max | 4 | 2.5 | 3.0Max | Bal | 0.5Max | 1.1 | 180/500 | Glass molds or other molds | ||||||

| Ni37M | 35 | 0.15 | 4.5 | 2.8 | Bal | 0.5Max | 1 | 180/500 | Glass molds, forging dies and heads | |||||||

| Ni40AA | 40 | 0.3 | 7.5 | 3.5 | 2.3 | 0.1 | Bal | 1.7 | 150/300 | Screw conveyors, forging mold parts | ||||||

| Ni46M | 46 | 0.05 | 6.54 | 2.8 | 1 | Bal | 1 | 180/500 | Glass molds or other molds | |||||||

| Ni50AA | 50 | 0.45 | 11 | 4 | 2.7 | 1 | Bal | 2.2 | 150/300 | Forging heads, valves | ||||||

| Ni55 | 53 | 0.4 | 15 | 4.3 | 5.0Max | 2.5 | Bal | 3.1 | 150/300 、53/20μm | Grinding tools, cam gears, pistons, exhaustvalves | ||||||

| Ni65AA | 56 | 1 | 18 | 5.3 | 5.0Max | Bal | 1.9 | 100/270 | Forging, molds, extrusion screws | |||||||

| Ni60AA | 60 | 0.78 | 15.9 | 4.55 | 5.0Max | / | Bal | / | / | 150/300 、53/20μm | Pistons, valves, pump blades, extrusion screws | |||||

| Ni60A | 60 | 0.7 | 15 | 4 | 8.0Max | Bal | 3.2 | 150/300 | Pistons, valves, pump blades, extrusion screws | |||||||

| Ni60 | 60 | 0.8 | 16 | 4 | 15.0Max | Bal | 3.2 | 150/300 | Pistons, valves, pump blades, extrusion screws | |||||||

| Ni60S | 60 | 0.8 | 15.5 | 3.8 | 0.1 | Bal | 3.4 | 150/400 | Extrusion screws | |||||||

| ND500 | 52 | 1.2 | 20.5 | 2.9 | 3.0Max | 5.5 | Bal | 13 | 2.3 | 100/270 | Specially used for extrusion equipment, injection molding extrusion screws oxyacetylene weld overlaying | |||||

| NF601 | 60 | 0.78 | 15.5 | 3.2 | 5.0Max | 2.5 | Bal | 3 | 4 | 150/400 | Specially used for extrusion equipment, injection molding extrusion screws oxyacetylene weld overlaying | |||||

| Ni60B | 60 | 0.6 | 17.1 | 3.1 | 25 | Bal | 4 | 150/300 、53/20μm | Pistons, extrusion molds, pump blades, extrusion screws | |||||||

| Ni60AACuMo | 58 | 0.5 | 15.5 | 4 | 3.0Max | 2.5 | Bal | 3.5 | Cu:2.5 | 150/300 、53/20μm | Pistons, extrusion molds, pump blades, extrusion screws | |||||

| Ni60ACuMo | 60 | 0.8 | 15.5 | 4 | 15.0Max | 1 | Bal | 3.5 | Cu:1.0 | 150/300 | Pistons, extrusion molds, pump blades, extrusion screws | |||||

| Ni60W | 62 | 0.8 | 16 | 4 | 15.0Max | Bal | 3.3 | 150/300 | Pistons, pump blades | |||||||

| Ni60CuMoW | 60 | 0.6 | 16 | 4 | 4 | 2 | Bal | 4 | Cu:2.0 | 300/500 | Pistons, pump blades, bail valves | |||||

| Ni220 | 31 | 0.15 | 5 | 3 | 2 | Bal | 2.2 | A1:0.9 | 100/270 | Glass molds for preliminary molding | ||||||

| Ni220M | 26 | 0.05Max | 4.5 | 3.2 | 3.0Max | Bal | 1 | A1:0.8 | 100/270 | Glass molds for preliminary molding | ||||||

| Ni330 | 37 | 0.1 | 5 | 3.5 | 6 | Bal | Cu:2.5 | 1.2 | 100/270 | Glass molds for preliminary molding | ||||||

| Ni22APTA | 28 | 0.05Max | 4.5 | 3.8 | 3 | Bal | 1 | 100/270 | Glass molds for preliminary molding | |||||||

Nickel Based Super Alloy Powder

| Grade | Chemical Composition | Particle Size | Application | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | ||||||||||

| NiCr20 | 0.2Max | 20 | 1 | 0.5Max | Bal. | 0.5Max | 53-20μm | Bonding layer for WC coationgs | ||||||||||

| NiCr50 | 1.0Max | 50 | 1 | 0.5Max | Bal. | 0.5Max | 106-45μm | Pulp-making pump, powder generation boilers, parts in a corrosive environment containing vanadium and sulphur | ||||||||||

| Ni625 | 0.1 | 23 | / | / | 5 | 8.0-10.0 | Bal. | / | / | 53-20μm | Parts subject to seawater corrosion, such as , in aerospace or aeronautical industry and chemical processing | |||||||

| Ni-C | 0.1 | 16.5 | 0.9 | 4.5 | 5.5 | 17 | Bal. | 2.0Max | 0.9 | 53-20μm | Paper-making machine | |||||||

| Ni-SuperC | 0.05Max | 23 | 18 | Bal. | 53-20μm | Paper-making machine | ||||||||||||

| Ni276 | 0.01Max | 15.5 | 0.03 | 4 | 16 | Bal. | 2.5Max | 1 | 53-20μm | Temperature oxidation | ||||||||

| Mn400 | 0.15Max | 1.25 | 1.5 | Ti:2.0 | Bal. | 3.5 | 53-20μm | Chemical or petrochemical processing equipment parts | ||||||||||

Nickel Coated Tungsten Carbide Powder

| Grade | Hardness (HRC) | Chemical Composition | Particle Size | Application |

|---|---|---|---|---|

| NiWC5 | 60 | 95%Ni60+5%WC | 150/300、150/400 | Extrusion screws, barreis, postons |

| NiWC10 | 62 | 90%Ni60+10%WC | 150/300、150/400 | Extrusion screws, barreis, postons |

| NiWC15 | 62 | 65%Ni60+15%WC | 150/300、150/400 | Valves, pistons |

| NiWC20 | 63 | 65%Ni60+20%WC | 150/300、150/400 | Valves, wire drawing dies, pistons |

| NiWC25 | 63 | 65%Ni60+25%WC | 150/300、150/400 | Valves, wire drawing dies, pistons |

| NiWC35 | 65 | 65%Ni60+35%WC | 150/300、150/400 | Wire drawing pulling wheels, fen blades, screw conveyors |

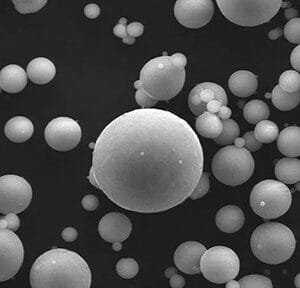

Spherical Nickel Based Alloy Powder

Grade: In718/GH4169/F3055, In625/GH3625/F3056, In939, Hastelloy X/GH3536, Waspaloy/GH738, HA188/GH5188, In713C/K418, K465, K640, Rene′125/DZ125, DD6, DD402/CMSX-2, FGH95, FGH96, FGH97

Standard: GB/T 14992, ASTM F3055, ASTM F3049, ASTM F3187, GB/T 1480, GB/T 5329, GB/T 8180

Particle Size: 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm

Shape: Spherical, Ψ0≥0.85

Appearance: Gray

3D Printing Application: SLM, EBM, LMD

Other Application: PM, MIN, HIP, SP, Welding repair

Package: Vacuum packaging (Aluminum foil bag) or argon-filled protective packaging (Aluminum bottle)

Mechanical Properties of Nickel Based Powder

| Grade | Mechanical properties | ||

|---|---|---|---|

| σb(MPa) | σ0.2(MPa) | δ(%) | |

| In718 | 1350-1500 | 1140-1280 | 9-12 |

| 1340-1360 | 1130-1170 | 16-28 | |

| ≥1280 | ≥1040 | ≥12 | |

| In625 | 830-1140 | 550-820 | 30-40 |

| ≥830 | ≥410 | ≥30 | |

Chemical Composition of Nickel Based Powder

| Chemical Composition (wt.%) | Grade | |||

|---|---|---|---|---|

| In718/GH4169/F3055 | In 625/GH3625/F3056 | In713C/K418 | In939 | |

| Cr | 17.0-21.0 | 20-23 | 11.5-13.5 | 21.5-23.5 |

| Ni | 50.0-55.0 | Bal. | Bal. | Bal. |

| Co | <1.0 | <1.0 | 18-20 | |

| Al | 0.20-0.80 | ≤0.4 | 5.5-6.4 | 1.7-2.1 |

| Mo | 2.80-3.30 | 8-10 | 3.8-4.8 | |

| Mn | ≤0.35 | ≤0.5 | ||

| Ti | 0.65-1.15 | ≤0.4 | 0.5-1.0 | 3.5-3.9 |

| Nb | 4.75-5.50 | 3.15-4.15 | 1.8-2.5 | 0.8-1.2 |

| B | ≤0.006 | 0.004-0.015 | ||

| C | ≤0.08 | ≤0.1 | 0.08-0.16 | 0.13-0.18 |

| Si | ≤0.35 | ≤0.5 | ||

| P | ≤0.015 | ≤0.015 | ||

| S | ≤0.015 | ≤0.015 | ||

| Cu | ≤0.30 | |||

| O | ≤0.02 | ≤0.02 | ≤0.01 | ≤0.003 |

| Fe | Bal. | ≤5 | ≤1.0 | |

| W | 1.8-2.2 | |||

| Ta | 1.2-1.6 | |||

| Zr | 0.05-0.14 | |||

Reviews

There are no reviews yet.