Palladium Sputtering Target Description

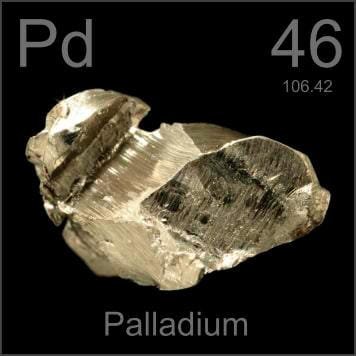

Palladium sputtering targets exhibit the same properties as their source material, palladium. As a member of the platinum group of metals, palladium is a lustrous silver-white metal with a face-centered cubic crystalline structure. At normal temperatures, it is highly resistant to corrosion from air and most acids. However, it can be attacked by hot acids and dissolves in aqua regia. Palladium forms numerous compounds and several complex salts.

This metal is known for its excellent corrosion resistance but is soluble in oxidizing acids and fused alkalis. One notable characteristic of palladium is its ability to absorb hydrogen gas—up to 900 times its own volume. Despite this, its primary use is as a catalyst for hydrogenation processes.

Palladium Sputtering Target Specifications

| Material Type | Palladium |

| Symbol | Pd |

| Melting Point | 1,554 °C |

| Color/Appearance | Silvery White Metallic |

| Theoretical Density | 12.02 g/cc |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Can alloy with refractory metals. |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Palladium Sputtering Target Application

High-performance palladium sputtering targets are essential for various thin-film coating applications, including CD-ROM production, decorative coatings, flat panel displays, and functional coatings. They are also used in the optical information storage industry, glass coating industry (such as car and architectural glass), and optical communications.

Other significant applications of palladium metal include:

- Catalytic Converters: Palladium is a crucial component in catalytic converters, helping to reduce harmful emissions from internal combustion engines.

- Catalyst in Polyester Production: It plays a key role in the production of polyester, acting as an important catalyst.

- Emission Reduction: Palladium is used to eliminate harmful emissions from internal combustion engines.

- Purification of Nitric Acid: It is instrumental in the purification process of nitric acid.

- Synthetic Rubber and Nylon Production: Palladium aids in the development of raw materials for synthetic rubber and nylon, contributing to these vital manufacturing processes.

Palladium Sputtering Target Bonding Service

Specialized bonding services for Palladium Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Palladium Sputtering Target Handling Notes

Packing

Our Palladium Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation.

Get Contact

TFM offers Palladium Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.