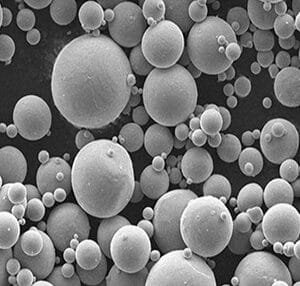

Overview of Spherical Cobalt-based Powder (CoCrW)

Spherical cobalt-based powder, known for its remarkable properties, is a versatile material with exceptional high-temperature resistance, strength, corrosion resistance, and elasticity. This powder is widely utilized in the manufacturing of precision components and is also suitable for producing medical implants such as bone replacements and dental prosthetics.

Specifications of Spherical Cobalt-based Powder (CoCrW)

| Particle size | 0-25,15-53,45-105,75-105μm |

| Form | spherical |

| Flowability | ≤18s |

| Apparent density | ≥4.2g/cc |

| Oxygen content | ≤200ppm |

| Nitrogen content | ≤100ppm |

| Composition(%) | Cr:26.5-29; Fe≤0.6; W:7.0-9.0; Mn≤0.4; Si:1.2-1.9; Co:Bal |

| Tensile strength(Mpa) | 330±50 |

| Yield strength(Mpa) | 220±30 |

| Ductility (%) | 5±1 |

Applications of Spherical Cobalt-based Powder (CoCrW)

Beyond its role in 3D printing, this cobalt-based powder finds extensive use in:

- Magneto Fluids: Enhancing magnetic properties in various applications.

- High-Efficiency Catalysts: Boosting the performance of chemical reactions.

- High-Performance Electrode Materials: Supporting efficient energy storage and conversion.

- Efficient Combustion Agents: Improving combustion efficiency in various processes.

Packaging Options for Spherical Cobalt-based Powder (CoCrW)

Available packaging includes:

- Sizes: 2.5 kg, 5 kg, 25 kg, or customized quantities

- Containers: Plastic bottles, cans, or iron cans

Reviews

There are no reviews yet.