Thulium Oxide Sputtering Target Description

Thulium oxide sputtering target from TFM is an oxide sputtering material composed of thulium (Tm) and oxygen (O). This material is used in various applications, particularly in thin film deposition processes, where it serves as a source for creating high-quality thin films in electronics, optics, and other advanced technologies.

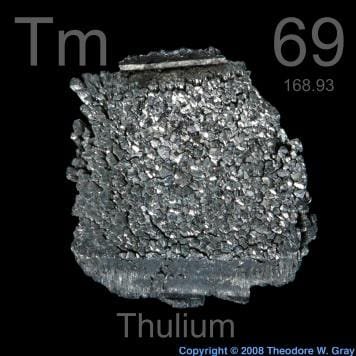

Thulium is a chemical element named after Thule, an ancient name for Scandinavia. It was first mentioned and observed by T. Cleve in 1879, who also successfully isolated it. Thulium is represented by the symbol “Tm” in the periodic table and has an atomic number of 69. It is positioned in Period 6, Group 3, within the f-block. The relative atomic mass of thulium is 168.93421(2) Dalton, with the number in brackets indicating the measurement uncertainty.

Related Product: Thulium Sputtering Target

Oxygen is a chemical element derived from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first identified in 1771 by the chemist W. Scheele, who also achieved its isolation. The chemical symbol for oxygen is “O,” and it is found in the periodic table at atomic number 8, positioned in Period 2 and Group 16, within the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, with the number in brackets reflecting the uncertainty of the measurement.

Oxygen is a chemical element derived from the Greek words ‘oxy’ and ‘genes,’ meaning acid-forming. It was first identified in 1771 by the chemist W. Scheele, who also achieved its isolation. The chemical symbol for oxygen is “O,” and it is found in the periodic table at atomic number 8, positioned in Period 2 and Group 16, within the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, with the number in brackets reflecting the uncertainty of the measurement.

Thulium Oxide Sputtering Target Specification

| Compound Formula | Tm2O3 |

| Appearance | White |

| Melting Point | 2,341° C |

| Density | 8600 kg/m3 |

Thulium Oxide Sputtering Target Packaging

Our Thulium Oxide Sputtering Target is meticulously tagged and labeled on the exterior to facilitate easy identification and ensure rigorous quality control. We take extensive precautions during storage and transportation to prevent any potential damage, thereby maintaining the high quality of our product.

Get Contact

TFM offers Thulium Oxide Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.