Tin (II) Sulfide Sputtering Target Description

The Tin (II) Sulfide sputtering target is a type of sulfide ceramic sputtering target composed of tin and sulfur, specifically in the form of tin (II) sulfide (SnS). This material is commonly used in various industrial applications, particularly in the production of thin films through sputtering processes. These thin films are utilized in a range of applications including semiconductors, photovoltaic devices, and other advanced technological components.

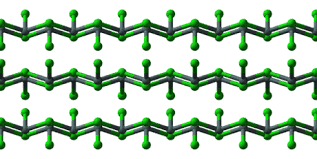

Tin (II) Sulfide (SnS) is a compound composed of tin and sulfur. It is typically found as a dark brown or black solid and is insoluble in water but can dissolve in concentrated hydrochloric acid. This material features a layered structure similar to that of black phosphorus, allowing it to be exfoliated into ultrathin flakes using ultrasonic methods in a liquid medium. These exfoliated SnS flakes possess a wider optical band gap, greater than 1.5 eV, compared to bulk crystals, making them potentially useful in various semiconductor applications, including photovoltaics and optoelectronic devices.

Related Product: Tin Sputtering Target

Tin (II) Sulfide Sputtering Target Specification

| Compound Formula | SnS |

| Appearance | Dark brown solid |

| Melting Point | 882 °C |

| Density | 5.22 g/cm3 |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

Tin (II) Sulfide Sputtering Target Application

The tin (II) sulfide sputtering target is widely utilized in various applications, including thin film deposition, decoration, semiconductor, display, LED, and photovoltaic devices. It is also employed in creating functional coatings and is used in industries such as optical information storage, glass coating (e.g., car glass and architectural glass), and optical communication. The material’s unique properties, such as its optical band gap and layer-structured semiconductor nature, make it suitable for these diverse applications, enhancing both the performance and functionality of the products it is used in.

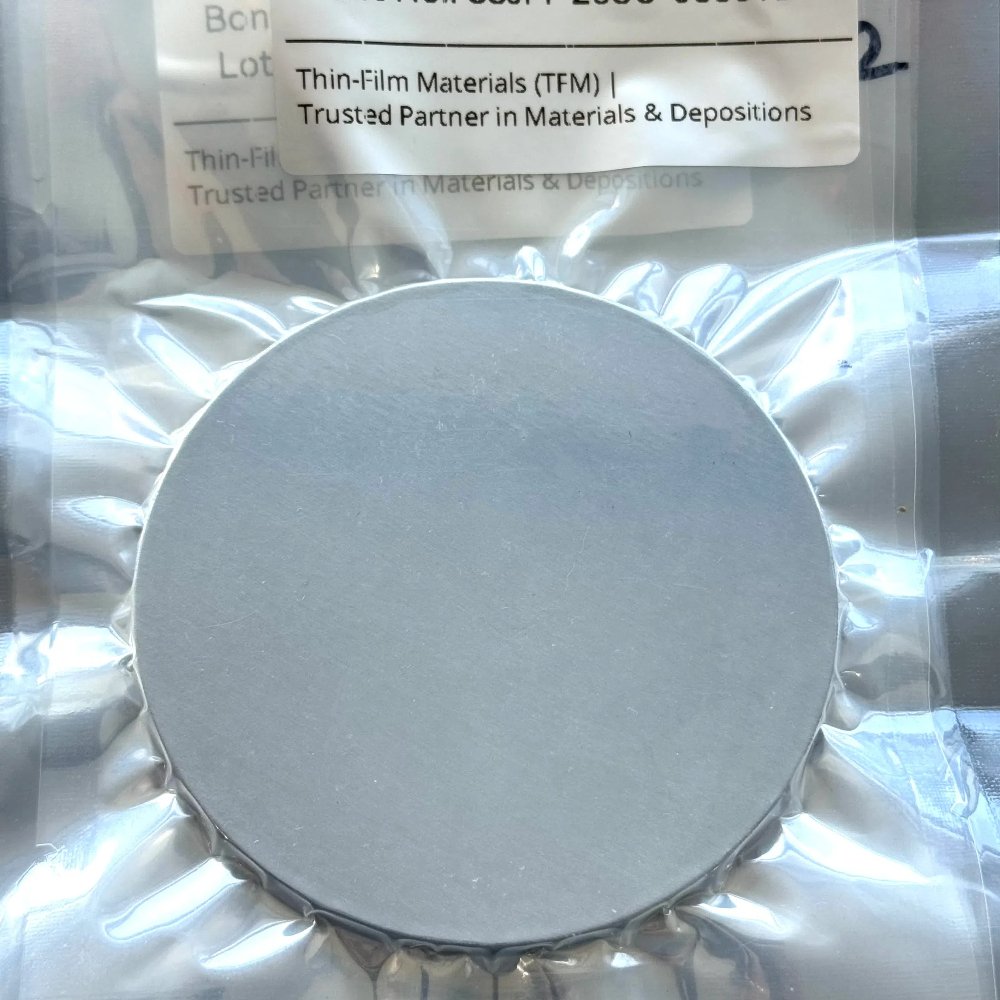

Tin (II) Sulfide Sputtering Target Packing

Our tin (II) sulfide sputter targets are meticulously tagged and labeled externally to guarantee efficient identification and maintain high standards of quality control. Special care is taken during storage and transportation to prevent any damage, ensuring that the products arrive in pristine condition for optimal use in various applications.

Get Contact

TFM offers tin (II) sulfide Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.