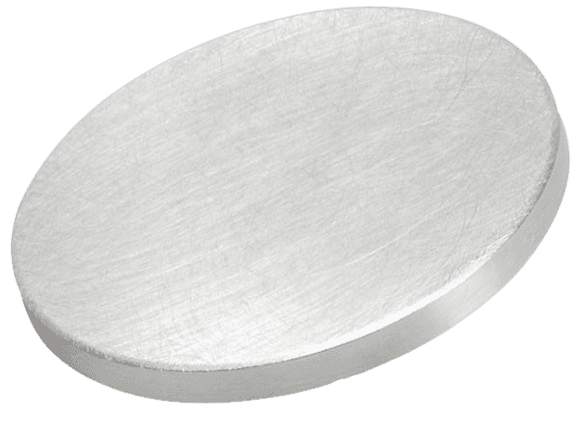

Tin Sputtering Target Description

Tin Sputtering Target Specification

| Material Type | Tin |

| Symbol | Sn |

| Color/Appearance | Silvery Lustrous Gray, Metallic |

| Melting Point | 232 °C |

| Density | 7.28 g/cc |

| Thermal Conductivity | 66.6 W/m.K |

| Coefficient of Thermal Expansion | 22 x 10-6/K |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Tin Sputtering Target Application

Tin sputtering targets are essential in the thin film deposition process and are widely used across various industries, including fuel cells, semiconductor production, displays, LED and photovoltaic devices, and glass coating. Tin also serves to coat other metals to prevent corrosion and is vital in several tin alloys such as soft solder, pewter, bronze, and phosphor bronze. These alloys possess unique properties that make them ideal for various applications. For instance, the niobium-tin alloy is crucial in the production of superconducting magnets.

MSDS File

MSDS File

Reviews

There are no reviews yet.