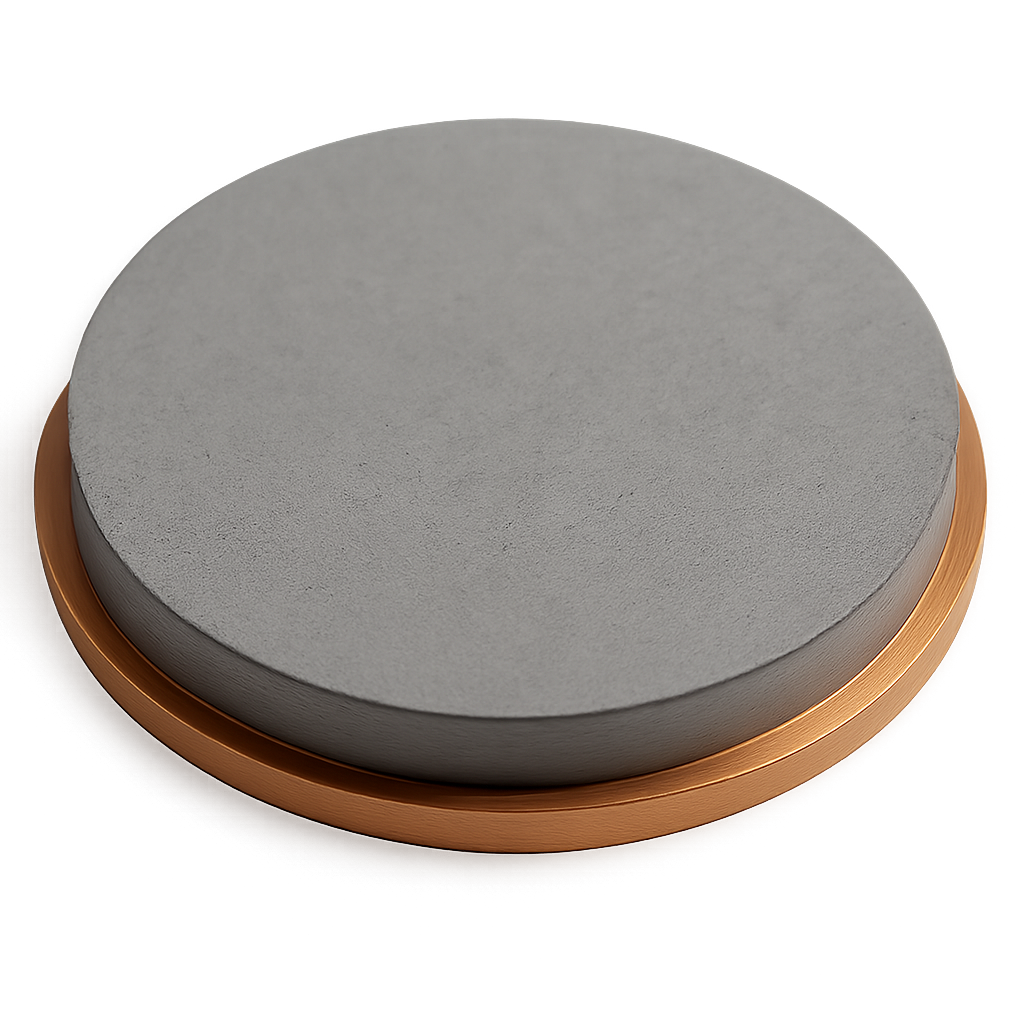

Introduction to Titanium Aluminum Boride (TiAlB₂) Sputtering Target

The Titanium Aluminum Boride (TiAlB₂) Sputtering Target is an advanced ceramic–metal composite target material designed for thin-film deposition. With a unique combination of titanium (Ti), aluminum (Al), and boron (B), this compound belongs to the family of complex borides, offering superior mechanical strength, excellent chemical stability, and multifunctional properties. It is widely used in the fabrication of hard, wear-resistant, and conductive films in both industrial and research applications.

Material Structure and Properties

Crystal Structure: TiAlB₂ is a layered ceramic compound where boron atoms form strong covalent bonds with Ti and Al, creating a highly stable lattice.

High Hardness: The presence of borides contributes to ultra-high hardness and excellent wear resistance.

Thermal & Oxidation Resistance: Ti and Al oxides form a protective barrier on the surface, making the compound resistant to high-temperature oxidation.

Electrical Conductivity: Unlike many ceramics, borides show relatively good conductivity, allowing efficient sputtering with both RF and DC power supplies.

Key Features of TiAlB₂ Sputtering Target

High Purity: Manufactured with purities up to 99.5–99.9% to minimize contamination in deposited films.

Excellent Film Uniformity: Ensures smooth, dense thin films with strong adhesion to substrates.

Versatile Deposition: Compatible with RF magnetron sputtering, DC sputtering, and pulsed laser deposition (PLD).

Mechanical Durability: Exhibits resistance to cracking during sputtering due to strong ceramic-metal bonding.

Applications

TiAlB₂ sputtering targets are highly valued in advanced engineering and coating technologies, including:

Hard Protective Coatings – Deposition of ultra-hard, wear-resistant films for cutting tools, dies, and mechanical components.

Electronics and Semiconductor Devices – Thin conductive barrier layers, interconnects, and diffusion-resistant coatings.

Aerospace & Automotive Components – Oxidation- and wear-resistant films for turbines, pistons, and high-stress environments.

Optical & Decorative Coatings – Provides films with unique reflectivity and surface hardness.

Research Applications – For developing multifunctional ceramic-metal films with tunable mechanical and electrical properties.

Fabrication & Deposition

Target Production: TiAlB₂ sputtering targets are typically produced through hot-pressing or high-temperature sintering methods, achieving high density (>95% theoretical).

Film Characteristics: Deposited films exhibit excellent hardness, chemical inertness, and thermal stability. Depending on the sputtering parameters, films can also show tunable electrical conductivity and optical reflectivity.

Reviews

There are no reviews yet.