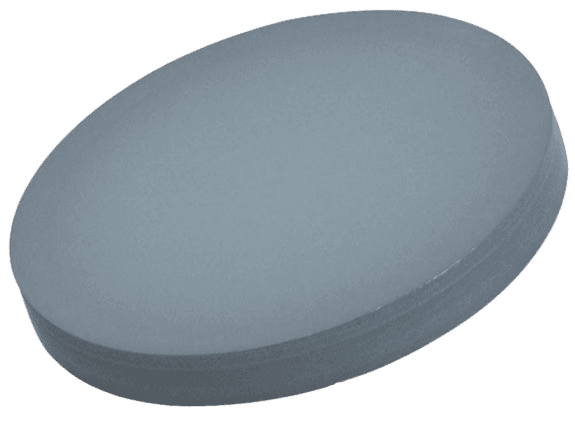

Titanium Dioxide Sputtering Target Description

Titanium Dioxide Sputtering Target Overview

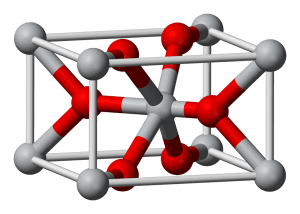

The Titanium Dioxide Sputtering Target from TFM is composed of titanium (Ti) and oxygen (O), with the chemical formula TiO2. Known as titanium(IV) oxide or titania, TiO2 naturally occurs as the minerals rutile, anatase, and in high-pressure forms such as akaogiite and brookite. Akaogiite, a monoclinic baddeleyite-like form, and brookite, an orthorhombic α-PbO2-like form, are both found at the Ries crater in Bavaria.

Sourcing and Characteristics

Titanium dioxide is primarily sourced from ilmenite ore, the most prevalent titanium dioxide-bearing ore globally. Rutile, the second most abundant form, contains approximately 98% titanium dioxide. The anatase and brookite phases are metastable and will irreversibly transform into the stable rutile phase when heated to temperatures between 600–800 °C (1,112–1,472 °F). This transformation is crucial for applications requiring the specific properties of the rutile phase, such as high refractive index and excellent UV resistance.

Titanium Dioxide Sputtering Target Specification

| Material Type | Titanium (IV) Oxide |

| Symbol | TiO2 |

| Color/Appearance | White-Beige, Gray-Black |

| Theoretical Density | 4.23 g/cc |

| Melting Point | 1,830 °C |

| Sputter | RF, RF-R |

| Type of Bond | Indium, Elastomer |

| Comments | Suboxide, must be reoxidized to rutile. Ta reduces TiO2 to TiO and Ti. |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Titanium Dioxide Sputtering Target Application

Titanium Dioxide TiO2 Sputtering Target Bonding Services

Specialized bonding services for titanium oxide Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Titanium Dioxide TiO2 Sputtering Target Packaging

Our titanium oxide sputter targets are meticulously handled to ensure they remain in pristine condition throughout storage and transportation. We take extra precautions to protect these products, preserving their quality and integrity so that they arrive at your facility ready for optimal use.

Reviews

There are no reviews yet.