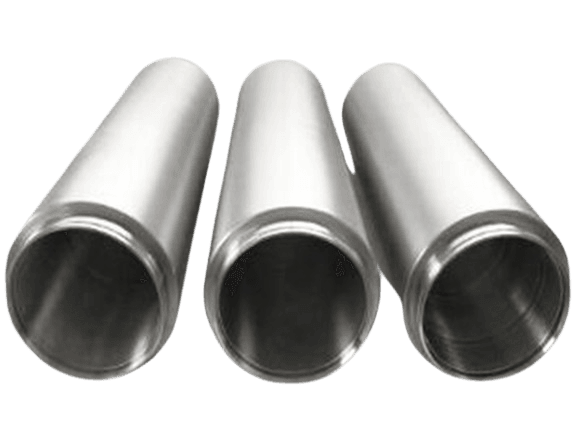

Titanium Ti Rotary Sputtering Target

TFM offers high-quality Titanium Ti rotary sputtering targets, ideal for thin-film deposition in a wide range of advanced applications, including semiconductors, coatings, and electronics. Titanium Ti targets are renowned for their high strength, light weight, and corrosion resistance, making them perfect for thin-film applications that require reliable performance in harsh environments.

The rotary sputtering target design ensures uniform and efficient deposition of Titanium Ti films, which are widely used in protective coatings, optical films, and electrical components. Titanium Ti films provide excellent adhesion, making them ideal for barrier layers and conductive films in electronics, photovoltaics, and magnetic storage devices. Additionally, Titanium nitride (TiN) films, created from Titanium targets, are highly valued in hard coating applications due to their superior wear resistance and high hardness.

Titanium Ti films are frequently used in decorative coatings for their aesthetic appeal and durability, as well as in catalyst supports for chemical reactions. Titanium oxide (TiO₂) films are also produced from Titanium targets and are widely employed in optical coatings, solar cells, and photocatalytic applications due to their optical properties and UV resistance.

TFM provides customized Titanium Ti rotary sputtering targets, ensuring precise control over material purity and composition to meet the requirements of high-performance applications. These targets deliver consistent and reliable results for thin-film deposition in industries such as electronics, solar energy, aerospace, and medical devices.

Our Titanium Ti rotary sputtering targets are manufactured to the highest standards, offering superior material quality and consistent sputtering performance. With low impurity levels, high density, and optimized sputtering characteristics, TFM’s Titanium Ti targets are ideal for producing high-quality thin films for next-generation technologies.

Specifications

| Materials | Titanium Rotary Sputtering Target |

|---|---|

| Symbol | Ti |

| Theoretical Density (g/cc) | 4.5 |

| Melting Point (°C) | 1660 |

| Production Method | Spraying Type, Monolithic Type |

| Size | As per customer’s drawings |

| Grain Sizes | <100 µm |

Applications

- Thin Film Photovoltaic Solar Industry

- Semiconductor Electronics Industry

- Flat Panel Display Industry

- Construction / Automotive Glass Industry

- Decorative / Functional Coating Industry

Reviews

There are no reviews yet.