Tungsten Powder Overview

Tungsten powder is a crucial raw material in the production of tungsten alloys. This versatile powder can be processed into various forms including wires, rods, tubes, and plates. By blending tungsten powder with other metal powders, a range of tungsten alloys can be created, such as tungsten-cobalt, tungsten-rhenium, tungsten-copper, and high-density tungsten alloys.

TFM offers high-quality tungsten powder and tungsten carbide powders with exceptional density. If you don’t see the specific powder you need, please reach out to us. We can also customize powder sizes to meet your requirements.

Characteristics of Tungsten Powder

General Uses

Tungsten powder is widely employed in numerous applications, including:

- Weight Fillers: Used in various products for increased weight.

- Radiation Shielding: Ideal for radiation protection, particularly in polymer mixtures.

- Metal Spray Industry: The unique particle shape and flowability make it suitable for metal spraying.

- Cemented Carbide Tools: Essential in making tools for turning, milling, drilling, and molding.

Chemical Composition

The chemical composition of tungsten powder varies by grade. Here’s a summary:

| Grade | W Content (%) | Fe | Al | Mg | Mn | Ni | As | Pb | Bi | Sn | Sb | Cu | Ca | Mo | K+Na | P | C | O |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FW-1 | ≥99.95 | 0.005 | 0.001 | 0.002 | 0.001 | 0.001 | 0.003 | 0.0015 | 0.0001 | 0.0001 | 0.0003 | 0.0001 | 0.0007 | 0.002 | 0.005 | 0.003 | 0.005 | 0.005 |

| FW-2 | ≥99.8 | 0.03 | 0.004 | 0.005 | 0.004 | 0.002 | 0.004 | 0.002 | 0.0005 | 0.0005 | 0.0005 | 0.001 | 0.001 | 0.002 | 0.005 | 0.009 | 0.004 | 0.01 |

| FW-3 | ≥99.8 | 0.03 | 0.005 | 0.01 | 0.004 | 0.004 | 0.005 | 0.002 | 0.0007 | 0.0007 | 0.0007 | 0.001 | 0.002 | 0.004 | 0.01 | 0.003 | 0.004 | 0.01 |

Special requirements can be arranged through discussions between the supplier and buyer.

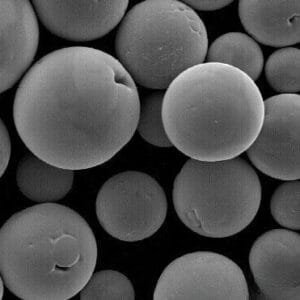

Spherical Tungsten Powder

TFM also provides spherical tungsten powder ideal for 3D printing applications. This spherical form of tungsten powder boasts high density, a high melting point, excellent electrical and thermal conductivity, making it a top choice for electrical and microelectronic applications.

Physical Properties

| Size | 15-53 um | ||||

| Apparet density | 10.51 g/cm3 | ||||

| Tap density | 12.46 g/cm3 | ||||

| Hall flow rate | 5.82 s/50g |

Chemical Composition

| Chemical Composition – by ICP-AES | ||||||||

| Element | W | Al | Si | Mg | Mn | Ni | As | Pb |

| Value (%) | ≥99.9 | <0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Element | Sn | Sb | Cu | Ca | Mo | K+Na | ||

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | ||

| Gas Impurities | ||||||||

| Element | C | P | O | N | ||||

| Value (%) | 0.002 | 0.001 | 0.015 | 0.003 | ||||

Features

- High Density

- High Purity

- High Melting Point

Applications of Tungsten Powder

Tungsten powder is used across various industries including:

- Nuclear Applications

- Automotive Industry

- Medical Instruments

- Metal Injection Molding (MIM)

- Additive Manufacturing (AM)

- Thermal Spray Applications (TSA)

Packaging

Tungsten powder is packed in iron drums, each containing 100kg or 200kg of powder, with plastic bags lining the inside to ensure quality and safety.

Reviews

There are no reviews yet.