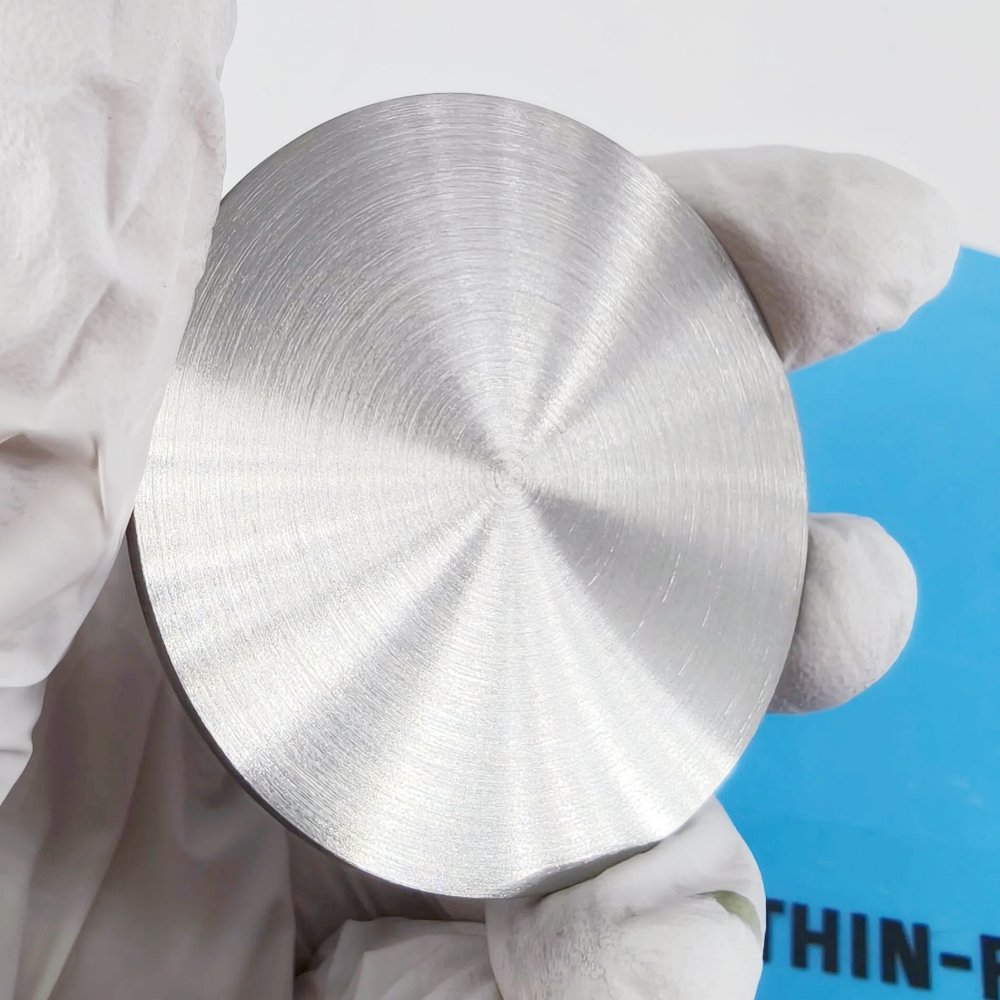

Tungsten Sputtering Target Description

Tungsten sputtering targets are crafted from high-purity tungsten metal. Tungsten, also known as wolfram, is a rare metal that naturally occurs almost exclusively in chemical compounds. Discovered in 1781 and isolated as a metal by 1783, tungsten’s significant ores include wolframite and scheelite.

Unmatched Physical Properties

- Highest Melting Point: Tungsten has the highest melting point of all elements at 3422 °C, making it ideal for use in extreme temperatures.

- Extraordinary Boiling Point: With a boiling point of 5930 °C, tungsten targets are excellent for high-performance applications.

- Exceptional Density: Tungsten has a density comparable to uranium and gold, being 19.25 times that of water, which suits applications requiring a heavy mass in a small volume.

- Intrinsic Hardness: While polycrystalline tungsten is inherently hard and brittle, our single-crystalline tungsten targets offer enhanced ductility, making them suitable for various industrial processes.

Tungsten Sputtering Target Specifications

| Material Type | Tungsten |

| Symbol | W |

| Color/Appearance | Grayish White, Lustrous, Metallic |

| Melting Point | 3422°C |

| Density | 19.3 g/cm3 |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Forms volatile oxides. Films hard and adherent. |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Tungsten Sputtering Target Application

Enhanced Services

Tungsten Sputtering Target Packing

Frequently Asked Questions (FAQs)

Q1: What are the benefits of using tungsten sputtering targets in industrial applications?

A1: Tungsten targets offer exceptional thermal and electrical conductivities, making them crucial for applications that require extreme temperature resistance and durability.

Q2: Can I order tungsten sputtering targets in custom dimensions?

A2: Yes, we provide targets in various shapes and sizes, tailored to meet specific application needs.

Q3: How do you ensure the quality of your tungsten targets?

A3: Each target undergoes rigorous quality control processes to maintain high purity and structural integrity.

Q4: What kind of support services do you offer for tungsten targets?

A4: We offer comprehensive bonding services and detailed technical support to ensure optimal performance and ease of use.

Why Choose Our Tungsten Targets?

Get Contact

TFM offers Tungsten Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.