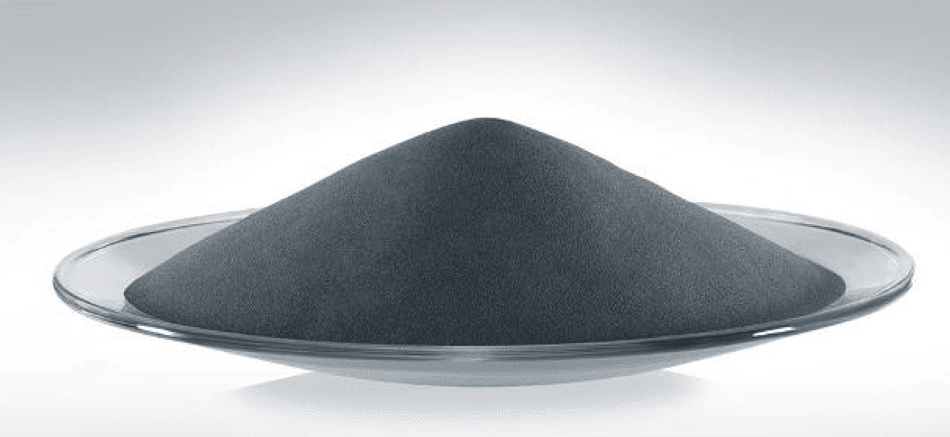

Molybdenum powder, a finely milled form of the metallic element molybdenum, is an essential material across various industries due to its unique chemical, physical, and mechanical properties. This versatile powder is widely appreciated for its high melting point, exceptional strength, and resistance to corrosion and oxidation. Below is an in-depth exploration of the applications of molybdenum powder, its benefits, and how it contributes to advancements in multiple fields.

Industrial Applications

1. Metal Alloys

One of the primary uses of molybdenum powder is in creating metal alloys. Its excellent thermal and mechanical properties make it an ideal additive in high-performance alloys.

- Steel Manufacturing: Molybdenum powder is a critical component in producing high-strength steels, including stainless steel and tool steel. These alloys are used in construction, automotive parts, and industrial equipment because they are resistant to wear, corrosion, and high temperatures.

- Superalloys: Molybdenum improves the strength and temperature resistance of superalloys used in jet engines, power plants, and chemical plants.

- Titanium Alloys: The addition of molybdenum powder enhances the mechanical strength and resistance to deformation in titanium alloys used in aerospace and medical implants.

2. Thermal Spray Coatings

Molybdenum powder is frequently used in thermal spray coatings. It forms a protective barrier on surfaces exposed to extreme heat and wear, such as:

- Industrial Tools: Coated tools last longer due to reduced wear and tear.

- Automotive Components: Molybdenum-coated parts, such as piston rings and cylinder bores, have improved durability and reduced friction.

Electronics and Electrical Applications

1. Semiconductors

Molybdenum powder plays a vital role in semiconductor manufacturing. It is used to create thin films for transistors and integrated circuits because of its excellent electrical conductivity and stability under high temperatures.

2. Electrical Contacts

Due to its low thermal expansion and high electrical conductivity, molybdenum powder is a material of choice for electrical contacts and electrodes in switches, circuit breakers, and welding applications.

3. Solar Cells

Molybdenum powder is used to manufacture thin films in photovoltaic cells, enhancing their efficiency. It serves as a back contact material in CIGS (copper indium gallium selenide) solar panels, offering excellent adhesion and electrical conductivity.

Aerospace and Defense Applications

1. Rocket and Missile Components

The aerospace and defense sectors leverage molybdenum powder for its heat resistance and strength. It is used in manufacturing rocket nozzles, missile components, and heat shields.

2. Aerospace Structural Components

Molybdenum alloys produced from molybdenum powder are used in aircraft parts due to their ability to withstand high-stress conditions without deformation.

3. Radiation Shielding

Molybdenum is used in protective coatings for radiation shielding in spacecraft and other equipment exposed to cosmic radiation.

Medical Applications

1. X-Ray Equipment

Molybdenum powder is used to create components for X-ray tubes and other medical imaging equipment. Its properties allow efficient generation and transmission of X-rays.

2. Medical Implants

The biocompatibility of molybdenum alloys makes them suitable for use in medical implants, including joint replacements and dental implants.

Energy Sector Applications

1. Nuclear Power

Molybdenum powder is critical in nuclear reactors due to its ability to maintain structural integrity under high temperatures and radiation. It is used in fuel rod claddings and structural supports.

2. Hydrogen Production

As a catalyst, molybdenum powder facilitates hydrogen production in electrolyzers and fuel cells, contributing to the growing hydrogen economy.

Chemical Industry

1. Catalysts

Molybdenum-based catalysts are essential in the chemical industry for processes like hydrodesulfurization, which removes sulfur from crude oil. These catalysts are highly efficient and stable under extreme conditions.

2. Pigments

Molybdenum compounds, derived from molybdenum powder, are used in creating pigments for plastics, paints, and ceramics. These pigments offer vibrant colors and durability.

Additive Manufacturing

1. 3D Printing

Molybdenum powder is gaining traction in 3D printing applications. It enables the production of complex, high-strength parts used in aerospace, automotive, and medical industries.

2. Powder Metallurgy

In powder metallurgy, molybdenum powder is sintered into components with excellent mechanical properties. These components are used in cutting-edge technologies and machinery.

Environmental Applications

1. Water Treatment

Molybdenum powder is used in filters and membranes to remove impurities from water, contributing to cleaner and safer water supplies.

2. Air Purification

Molybdenum compounds are used in catalysts for air purification systems, reducing harmful emissions from industrial and automotive sources.

Research and Development

Molybdenum powder is extensively used in R&D to explore advanced materials and processes. It is pivotal in developing:

- Nanotechnology: Molybdenum nanoparticles are used in creating high-strength composites.

- Superconductors: Molybdenum-based materials are being studied for their potential in superconducting technologies.

Key Advantages of Molybdenum Powder

- High Melting Point: Allows use in extreme temperatures.

- Corrosion Resistance: Provides durability in harsh environments.

- Thermal Conductivity: Ensures efficient heat dissipation.

- Electrical Conductivity: Enables use in electrical and electronic components.

- Strength-to-Weight Ratio: Ideal for lightweight and high-strength applications.

Future Prospects

The demand for molybdenum powder is expected to grow as industries continue to innovate and develop advanced technologies. Emerging applications in renewable energy, additive manufacturing, and advanced electronics will drive its significance in the coming decades.

Conclusion

Molybdenum powder is a critical material with diverse applications across industries. From enhancing the performance of metal alloys and electronic components to advancing medical technologies and environmental solutions, its versatility and unique properties make it indispensable. As industries evolve, the role of molybdenum powder is set to expand, solidifying its place as a cornerstone of modern innovation.