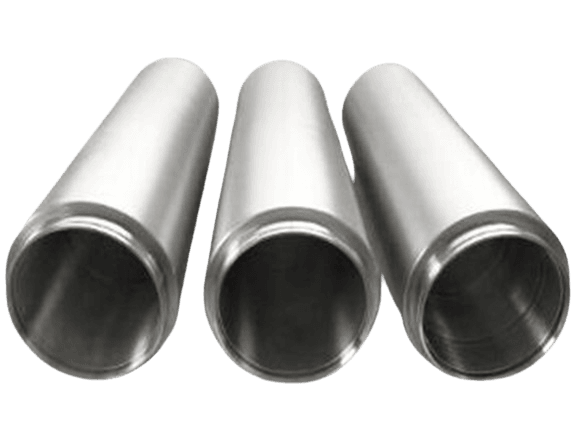

Rotatory Molybdenum Sputtering Target Description

The Rotatory Molybdenum Sputtering Target is a series of processed products made from high-purity molybdenum material, designed to have specific sizes and shapes. These targets are primarily used for vacuum coating applications. Molybdenum metal is silvery-white and very hard, with a melting point of 2623°C (4753°F), making it one of the elements with the highest melting points, only surpassed by tantalum, osmium, rhenium, and tungsten among natural elements. Additionally, molybdenum has one of the lowest coefficients of thermal expansion among metals in commercial use.

The Rotatory Molybdenum Sputtering Target is a series of processed products made from high-purity molybdenum material, designed to have specific sizes and shapes. These targets are primarily used for vacuum coating applications. Molybdenum metal is silvery-white and very hard, with a melting point of 2623°C (4753°F), making it one of the elements with the highest melting points, only surpassed by tantalum, osmium, rhenium, and tungsten among natural elements. Additionally, molybdenum has one of the lowest coefficients of thermal expansion among metals in commercial use.

Related Post: Molybdenum Sputtering Target

Rotatory Molybdenum Sputtering Target Specification

| OD | ID | L | |

| Dimension | 5.5”-7” | 5”-5.5” | <138” |

| Material Type | Molybdenum |

| Symbol | Mo |

| Color/Appearance | Grey, Metallic |

| Melting Point | 2,617 °C |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Films smooth, hard. Careful degas required. |

| Density | 10280 kg/m3 |

Rotatory Target VS. Planar Target

Compared to planar targets, rotary targets contain more material and offer greater utilization, resulting in longer production runs and reduced system downtime. This enhances the throughput of the coating equipment. Additionally, rotary sputter targets allow for the use of higher power densities because the heat build-up is spread evenly over the surface area of the target. Consequently, this leads to increased deposition speeds and improved performance during reactive sputtering.

Packaging

Our Rotatory Molybdenum (Mo) Sputtering Target are carefully handled to prevent damage during storage and transportation, ensuring the quality of our products is preserved in their original condition.

Reviews

There are no reviews yet.