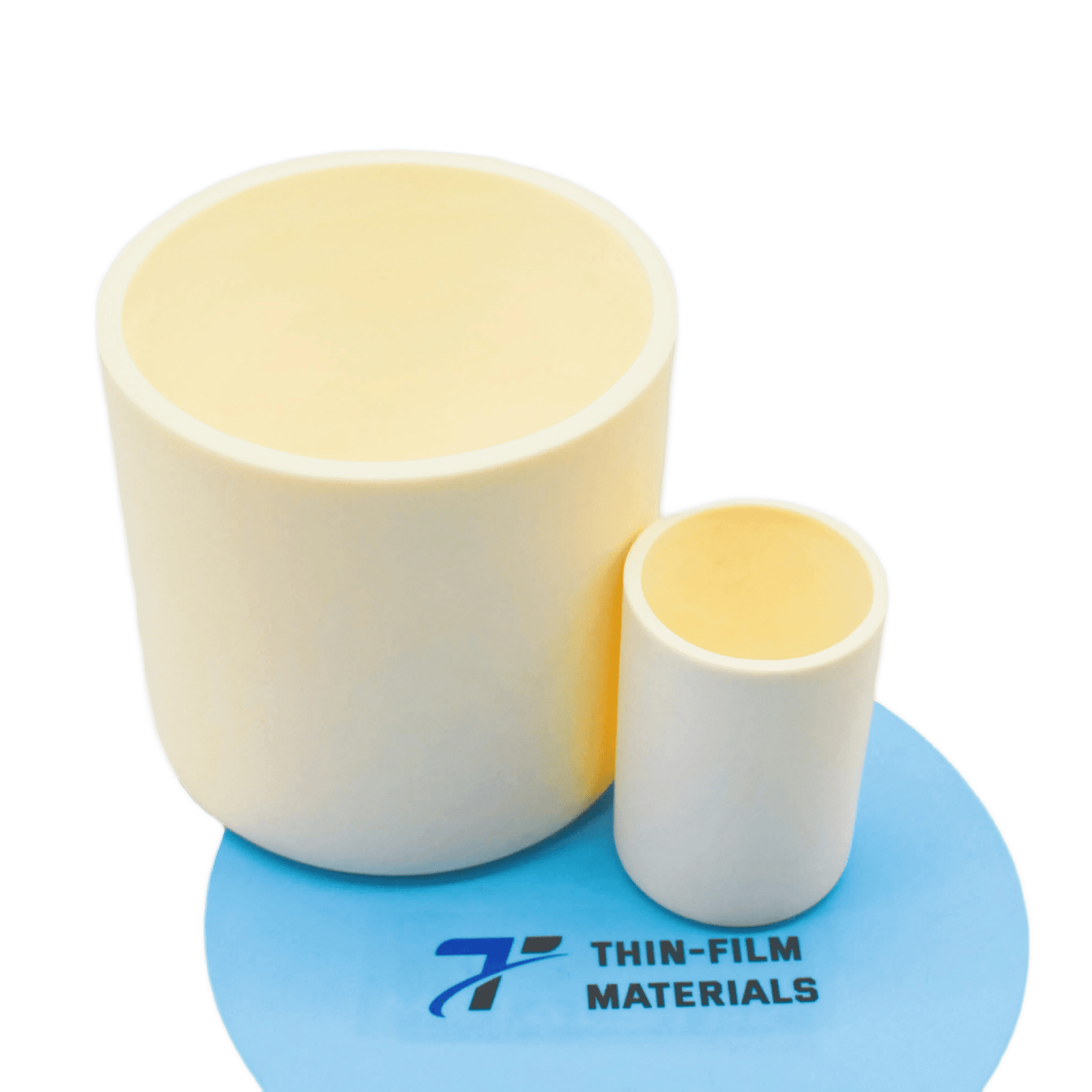

Overview of Alumina Crucibles

Alumina crucibles are ceramic components renowned for their excellent thermal conductivity, high compressive strength, and resistance to thermal shock. Their low thermal expansion rate makes them ideal for high-temperature applications, especially in furnaces, thermocouple sheaths, and tubes. Due to its exceptional hardness and wear resistance, alumina is commonly used in components like ball valves, piston pumps, and deep drawing tools. Furthermore, alumina can be bonded with metals and other ceramics through brazing and metalizing techniques. These crucibles withstand high temperatures without contaminating most molten metals, ensuring the purity of the materials being processed.

Alumina Crucible Properties

Key Specifications

| Specification | AL97 | AL98 |

|---|---|---|

| Al₂O₃ Content | 97% | 99.80% |

| Color | White | Ivory |

| Tensile Strength | 30 Kpsi | 32 Kpsi |

| Flexural Strength | 55 Kpsi | 60 Kpsi |

| Compressive Strength | 300 Kpsi | 330 Kpsi |

| Density | 3.70 g/cc | 3.92 g/cc |

| Hardness | 13.8 HV, GPa | 18 HV, GPa |

| Thermal Conductivity | 25 W/(m·K) | 32 W/(m·K) |

| C.O.T.E. | 7.7 In/In°C (x10⁷) | 7.8 In/In°C (x10⁷) |

| Operating Temperature | 1500 °C | 1750 °C |

| Dielectric Constant | 9.5 | 9.8 |

| Volume Resistivity | >10¹⁴ Ohm-cm | >10¹⁵ Ohm-cm |

| Dielectric Strength | 16 KV/mm | 20 KV/mm |

These properties demonstrate the versatility and durability of alumina crucibles, making them an ideal choice for various industries.

Common Applications of Alumina Crucibles

Alumina (Al₂O₃) crucibles are widely used across multiple sectors due to their durability and high-temperature performance. Here are some key applications:

- Semiconductor Manufacturing: Ideal for components in chemical vapor deposition (CVD), ion implantation, and photolithography processes.

- Industrial Equipment: Used for products like injector tubes, gas nozzles, and insulators in traditional industries.

- High-Temperature Furnaces: Maintains strength and hardness at elevated temperatures, making it perfect for industrial furnace parts.

- Thermocouple Protection: Serves as a protective layer for high-temperature thermocouples.

- Chemical Processing: Due to its resistance to corrosion, it is commonly employed in the chemical industry.

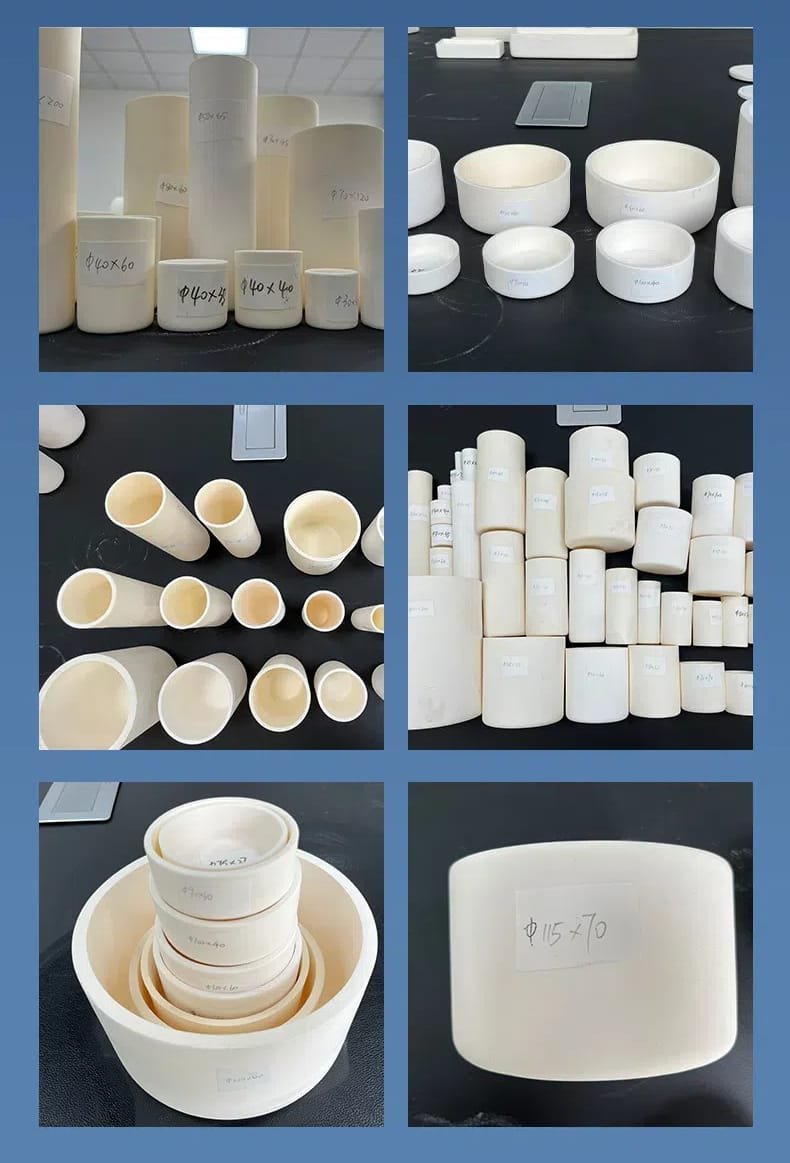

Alumina Crucible Productions (TFM Facilities)

Packaging and Handling

Alumina crucibles are packaged with the utmost care to prevent damage during transit and storage. This careful handling ensures the product arrives in optimal condition, preserving its integrity and performance.

This combination of properties and wide range of applications makes alumina crucibles essential in demanding industrial environments.

Reviews

There are no reviews yet.