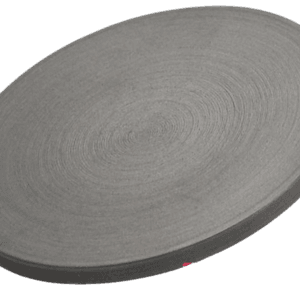

Aluminum Nitride Sputtering Target Description

Aluminum Nitride Sputtering Target from TFM is a ceramic sputtering material with the chemical formula AlN.

Aluminum, also known as aluminium, is a chemical element derived from the Latin word ‘alumen,’ meaning bitter salt. It was first identified in 1825 by H.C. Ørsted, who also succeeded in isolating it. The chemical symbol for aluminum is “Al,” and it is located in Period 3, Group 13 of the periodic table, classified within the p-block. Its atomic number is 13, and the relative atomic mass is 26.9815386(8) Dalton, with the figure in brackets representing the measurement’s uncertainty.

Aluminum, also known as aluminium, is a chemical element derived from the Latin word ‘alumen,’ meaning bitter salt. It was first identified in 1825 by H.C. Ørsted, who also succeeded in isolating it. The chemical symbol for aluminum is “Al,” and it is located in Period 3, Group 13 of the periodic table, classified within the p-block. Its atomic number is 13, and the relative atomic mass is 26.9815386(8) Dalton, with the figure in brackets representing the measurement’s uncertainty.

Related Product: Aluminum (Al) Sputtering Target

Nitrogen is a chemical element named after the Greek words ‘nitron’ and ‘genes,’ which mean nitre-forming. It was first identified in 1772 by Daniel Rutherford, who also successfully isolated the element. The chemical symbol for nitrogen is “N.” In the periodic table, nitrogen has an atomic number of 7 and is located in Period 2, Group 15, belonging to the p-block. The relative atomic mass of nitrogen is 14.0067(2) Dalton, with the number in brackets indicating the uncertainty in this measurement.

Nitrogen is a chemical element named after the Greek words ‘nitron’ and ‘genes,’ which mean nitre-forming. It was first identified in 1772 by Daniel Rutherford, who also successfully isolated the element. The chemical symbol for nitrogen is “N.” In the periodic table, nitrogen has an atomic number of 7 and is located in Period 2, Group 15, belonging to the p-block. The relative atomic mass of nitrogen is 14.0067(2) Dalton, with the number in brackets indicating the uncertainty in this measurement.

Aluminum Nitride Sputtering Target Specification

| Compound Formula | AlN |

| Appearance | White to pale yellow powder |

| Melting Point | 2200 °C |

| Boiling Point | 2517 °C |

| Density | 2.9 to 3.3 g/cm3 |

| Electrical Resistivity | 10 to 12 10x Ω-m |

| Specific Heat | 780 J/kg-K |

Aluminum Nitride Sputtering Target Packaging

Our aluminum nitride sputter targets are meticulously handled to prevent any damage during storage and transportation. This careful handling ensures the products remain in pristine condition, preserving their quality and integrity until they reach their final destination.

MSDS File

MSDS File

Reviews

There are no reviews yet.