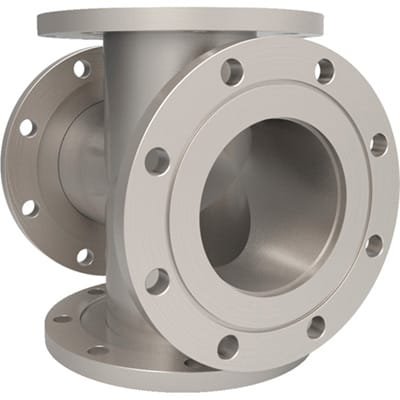

ASA HV 4-Way Crosses (flat flanges): Four-Port Vacuum Connectivity with All-Flat ASA Flanges for O-Ring Mating

ASA HV 4-Way Crosses (flat flanges) from TFM are engineered to provide consistent, sexed flange sealing in high-vacuum (HV) environments where grooved ASA flanges with o-rings are already in place. Fabricated from 304L stainless steel tubing, these crosses feature flat ASA flanges on all four orthogonal ports—making them ideal for mating with grooved flanges in systems that require secure, repeatable vacuum seals.

Each port is equipped with a rotatable flat flange, allowing precise alignment during assembly. This configuration supports vacuum compatibility down to 10⁻⁸ Torr and is well-suited for both industrial and laboratory use where cleanliness, mechanical strength, and system flexibility are key.

Key Features of ASA HV 4-Way Crosses (flat flanges):

All-Flat ASA Flange Design

Each of the four ports is fitted with a rotatable flat ASA flange, which pairs with grooved flanges that retain an elastomeric o-ring. This sealing method is trusted across high-vacuum systems for its simplicity and reliability.304L Stainless Steel Tubing

Ensures structural integrity, corrosion resistance, and long-term durability under thermal stress, aggressive gas environments, or frequent cycling.Rotatable Flanges for Easy Alignment

All flanges can be freely rotated to simplify installation and allow better orientation control in compact or custom assemblies.Leak-Tested and Vacuum Cleaned

Every ASA HV 4-Way Cross (flat flanges) is helium leak tested and cleaned to vacuum service standards, supporting ultra-clean applications.Available in Standard and Custom Sizes

Offered in common ASA flange sizes (4″, 6″, 8″, 10″, 12″), with custom tube lengths, wall thicknesses, and reducer configurations available upon request.

Common Applications:

Expansion of ASA vacuum systems using grooved flange standards

Diagnostic access ports and gas inlet/exhaust junctions

Multi-direction vacuum chamber interconnections

Foreline distribution hubs for HV systems

Modular assemblies in cleanrooms, analytical labs, or pilot lines

To complete your setup, TFM provides matching grooved ASA flanges, FKM or Buna-N o-rings, bolt kits, and blank flanges—ensuring full compatibility with ASA-style vacuum infrastructure.

In summary, ASA HV 4-Way Crosses (flat flanges) are the ideal solution for building or modifying high-vacuum assemblies where grooved flange interfaces and o-ring sealing are the standard. With rotatable flat flanges and stainless steel strength, these crosses provide dependable vacuum integrity in every direction.

Reviews

There are no reviews yet.