Germanium Phosphide Sputtering Target Description

Our Germanium Phosphide Sputtering Targets are engineered from top-tier materials to deliver exceptional performance and reliability. These advanced targets are designed to meet the precise demands of thin-film deposition technologies.

With their distinct Germanium Phosphide composition, these targets offer numerous advantages, including outstanding electrical conductivity, a high melting point, and remarkable chemical stability. These characteristics make them ideal for a wide range of applications, particularly in microelectronics, solar cell production, and other processes where precise material control is essential.

Whether you’re involved in cutting-edge research or advanced manufacturing, our Germanium Phosphide Sputtering Targets provide the quality and consistency you need. Our commitment to excellence ensures that these targets will enhance your thin-film deposition processes, delivering optimal results every time.

Related Product: Germanium Sputtering Target, Germanium Sulfide Sputtering Target

Germanium Phosphide Sputtering Target Specifications

| Compound Formula | GeP |

| Molecular Weight | 103.61 |

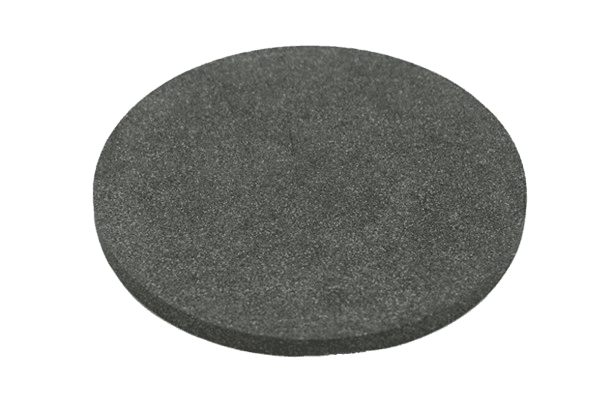

| Appearance | Black Target |

| Melting Point | 725 °C |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

Germanium Phosphide Sputtering Target Handling Notes

Indium bonding is highly recommended for Germanium Phosphide Sputtering Targets because certain characteristics of this material, such as brittleness and low thermal conductivity, make it challenging to sputter effectively. The low thermal conductivity also makes the material prone to thermal shock, which can compromise its integrity during the sputtering process. Indium bonding helps mitigate these issues, ensuring better performance and extending the target’s lifespan.

Germanium Phosphide Sputtering Target Application

Germanium Phosphide Sputtering Target Packaging

We take meticulous care in handling our Germanium Phosphide Sputtering Targets during both storage and transportation. Each target is packaged with precision to ensure it arrives in pristine condition, preserving its quality and performance throughout the delivery process.

Get Contact

TFM provides Germanium Phosphide Sputtering Targets in various forms, purities, and sizes to suit a wide range of applications. Our targets are meticulously crafted for high-purity physical vapor deposition (PVD) processes, ensuring exceptional density and minimal average grain sizes. These sputtering targets are ideal for use in semiconductor manufacturing, chemical vapor deposition (CVD), and PVD processes, as well as in display and optical applications.

Reviews

There are no reviews yet.